Optimum design method applied to industrial camera circuit board

An optimized design and industrial camera technology, applied to color TV parts, TV system parts, TV, etc., can solve the problems of high production cost, poor utilization rate, large size, etc., and achieve weight reduction, size reduction, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

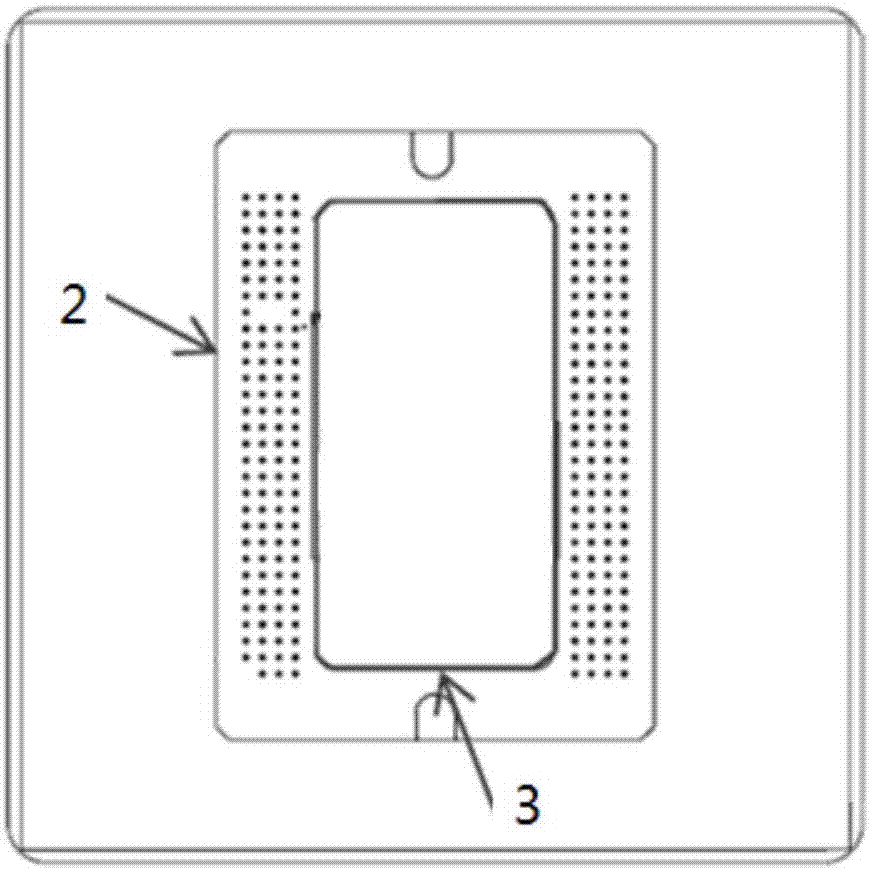

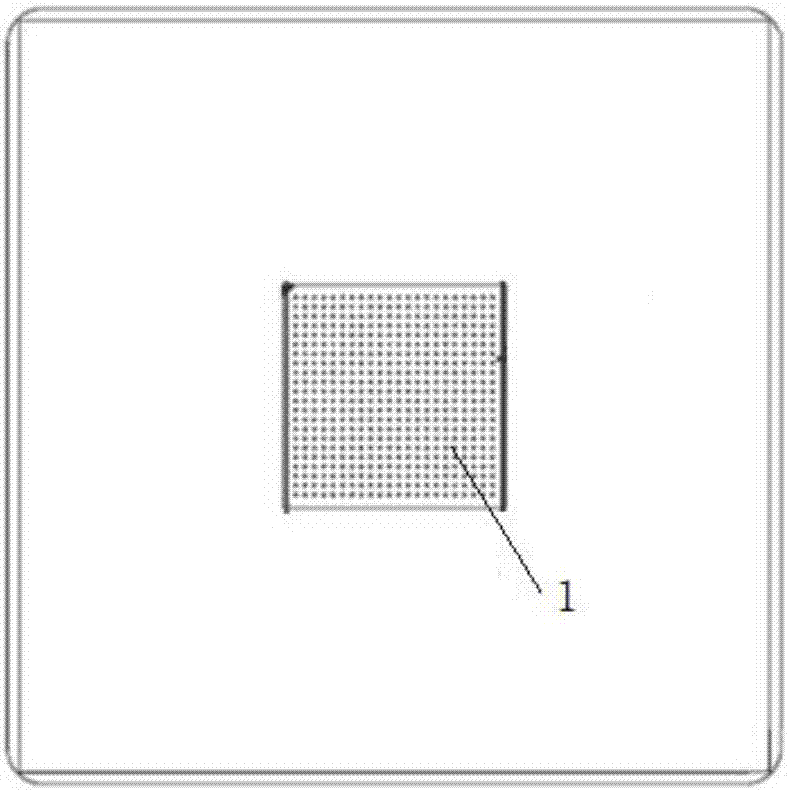

[0013] Specific implementation mode one, combination figure 1 with figure 2 The description of this embodiment is applied to the optimized design method of industrial camera circuit board, including image sensor and FPGA control chip. The FPGA control chip and the image sensor socket 2 are respectively laid out at the center of the front and the center of the back of the same circuit board. The image sensor socket 2 is packaged by BGA and has a leakage area 3 in the middle; the image sensor is inserted in the image On the sensor socket 2, the image sensor and the FPGA control chip are directly connected through a circuit board; the filter capacitor 1 of the FPGA control chip is arranged in the leakage area 3 of the image sensor socket.

[0014] In this embodiment, the FPGA control chip selects the smallest package model that meets the functional requirements, and the FPGAG control chip model selects the smallest package model as the XC6SLX100CSG484 model. A large number of filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com