Lens installation fixing device and installation fixing method thereof

A lens installation and fixing device technology, applied in installation, lens, optics and other directions, can solve the problems of low installation and fixation accuracy, poor stability, complex process, etc., and achieve the effects of easy installation and fixation of lenses, good stability, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

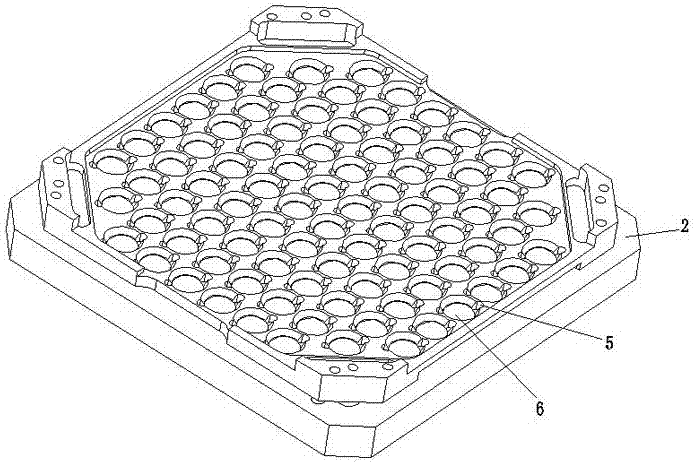

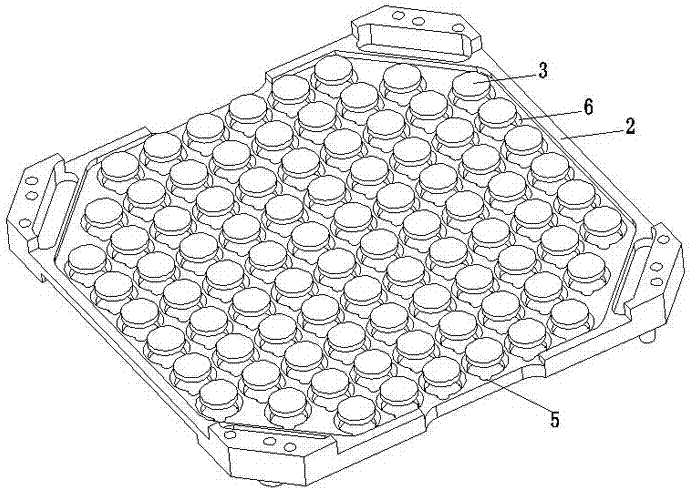

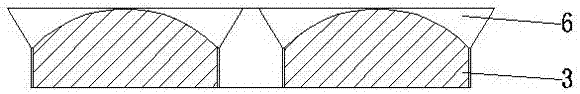

[0031] A schematic diagram of a lens installation and fixing device in this embodiment is as follows Figure 1 to Figure 3 As shown, the lens mounting bracket 2 is included, and the lens mounting bracket 2 is provided with several through holes 6 for placing the lens 3, and the lens mounting bracket 2 is also provided with a through hole 6 around each through hole 6. Connected glue injection hole 5. The glue injection hole 5 does not pass through the lens mounting bracket 2 .

[0032] A lens installation and fixing device of the present invention, by setting a through hole 6 and a glue injection hole 5 communicating with the through hole 6 in the lens installation bracket 2, after the lens 3 is placed in the through hole 6, glue is injected into the glue injection hole 5 , the glue permeates around the lens 3 and the through hole 6, and the lens 3 is adhered in the through hole 6, and the installation and fixing of the lens 3 can be completed after the glue is cured. The len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com