Emulsifying agent capable of improving compatibility of pigment and preparation method thereof as well as water-based fluorescent pigment color paste containing same and preparation method thereof

A fluorescent pigment and compatibility technology, applied in the field of fluorescent pigments, can solve the problems of spots, poor abrasion resistance of textiles, decreased washing resistance, etc., and achieve the effects of not easy to block the mesh, improved water resistance, and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

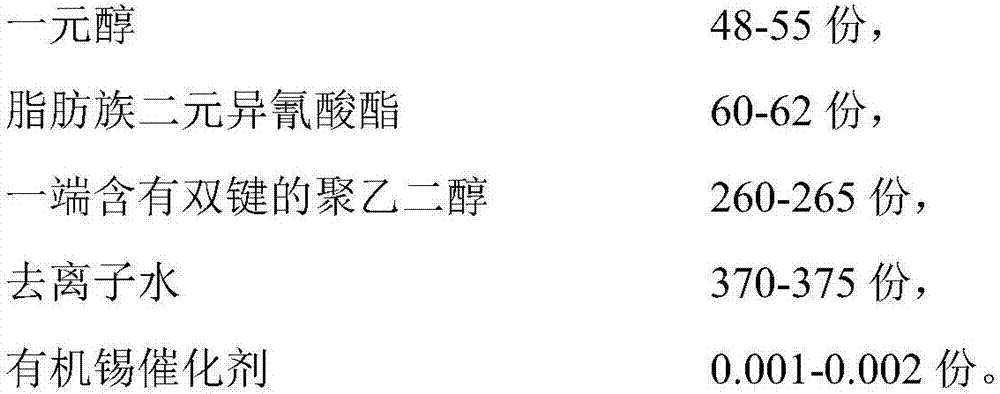

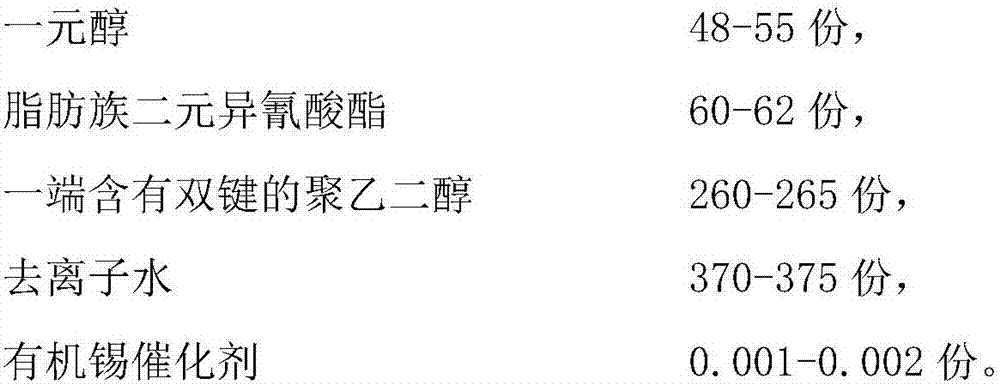

[0031] The preparation method of the emulsifier for improving the compatibility of pigments comprises the following steps: raising the temperature of the monohydric alcohol to 85±2°C, then adding an organic tin catalyst and an aliphatic diisocyanate, raising the temperature to 105-110°C and keeping it warm for 2-2.5 hours , after measuring that the NCO content reaches 10-20%, the temperature is lowered to 85±2°C (for the selection of different materials, the content of NCO groups after the completion of the reaction is different, such as the reaction with tridecyl alcohol and isophorone diisocyanate , NCO reaches 10% as the end point, and at this point in the reaction, the hydroxyl group of tridecyl alcohol reacts with the NCO group of isophorone diisocyanate to reach more than 95%, which meets the requirements of the follow-up reaction), and polyethylene glycol is dropped into the heat preservation reaction After 3.5-4.5 hours, add 370-375 parts of deionized water, cool down t...

Embodiment 1

[0057] 1) Preparation of non-ionic emulsifier: heat 50 parts of tridecyl alcohol to 85°C, then add 0.001 part of dibutyltin dilaurate and 61 parts of isophorone diisocyanate, heat up to 105 and keep it warm for 2 hours to measure the NCO content After reaching 10%, lower the temperature to 85°C, put in 262 parts of polyethylene glycol 1000, add 373 parts of deionized water after 4 hours of heat preservation reaction, drop to normal temperature and discharge, and obtain a nonionic emulsifier containing polyurethane segments.

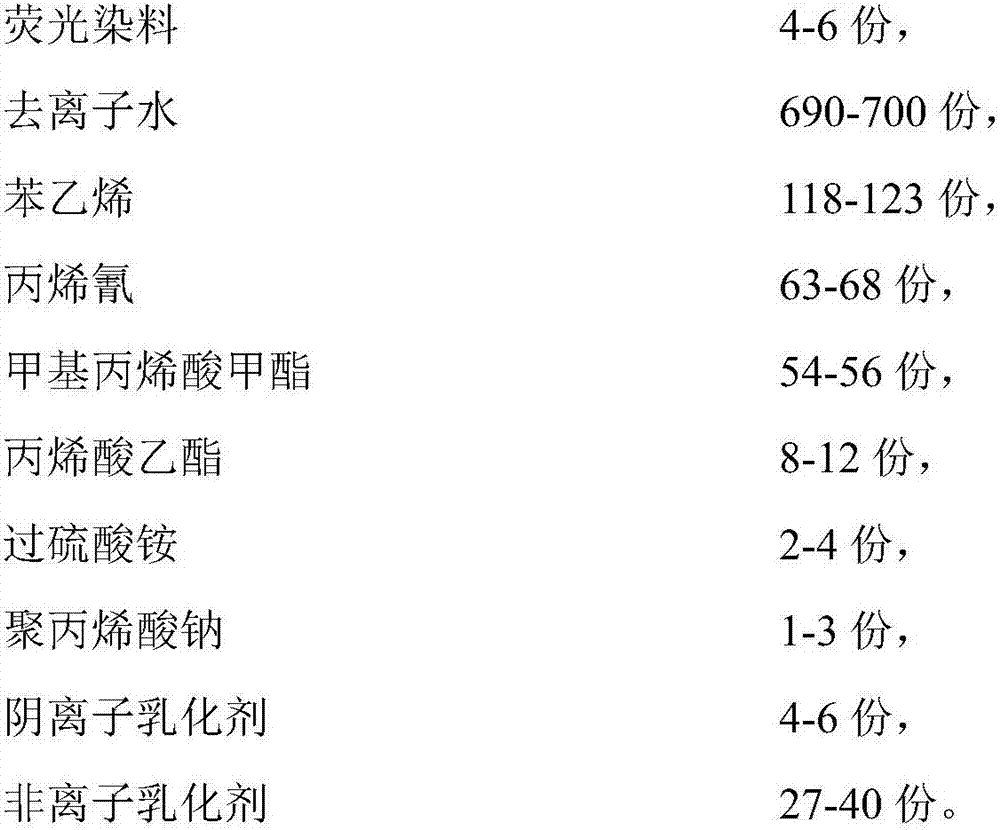

[0058] 2), preparation of aqueous phase liquid: 2 parts of sodium polyacrylate, 5 parts of sodium dodecylbenzenesulfonate, 5 parts of basic yellow 40 and 40 parts of nonionic emulsifier prepared above are dissolved in 635 parts of deionized water to obtain an aqueous phase liquid;

[0059] 3), prepare monomer solution: 120 parts of styrene, 65 parts of acrylonitrile, 55 parts of methyl methacrylate, 10 parts of ethyl acrylate, stir and dissolve to obtain ...

Embodiment 2

[0065] 1) Preparation of non-ionic emulsifier: heat 48 parts of dodecanol to 83°C, then add 0.0015 parts of dibutyltin diacetate and 60 parts of hexamethylene diisocyanate, heat up to 108°C and keep it warm for 2.5 hours. The measured NCO content reaches 15%. Afterwards, the temperature was lowered to 83° C., 260 parts of polyethylene glycol 1400 were put in, 370 parts of deionized water were added after 3.5 hours of heat preservation reaction, and the material was cooled to normal temperature to obtain a nonionic emulsifier containing polyurethane segments.

[0066] 2), preparation of aqueous phase liquid: 1 part of sodium polyacrylate, 4 parts of sodium dodecylbenzenesulfonate, 4 parts of rhodamine 6G and 27 parts of nonionic emulsifier prepared above are dissolved in 630 parts of deionized water to obtain aqueous phase liquid;

[0067] 3), prepare monomer solution: 118 parts of styrene, 63 parts of acrylonitrile, 54 parts of methyl methacrylate, 8 parts of ethyl acrylate, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com