Rotor for electric machine

A rotor and rotor body technology, applied in the direction of electromechanical devices, electrical components, electric components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

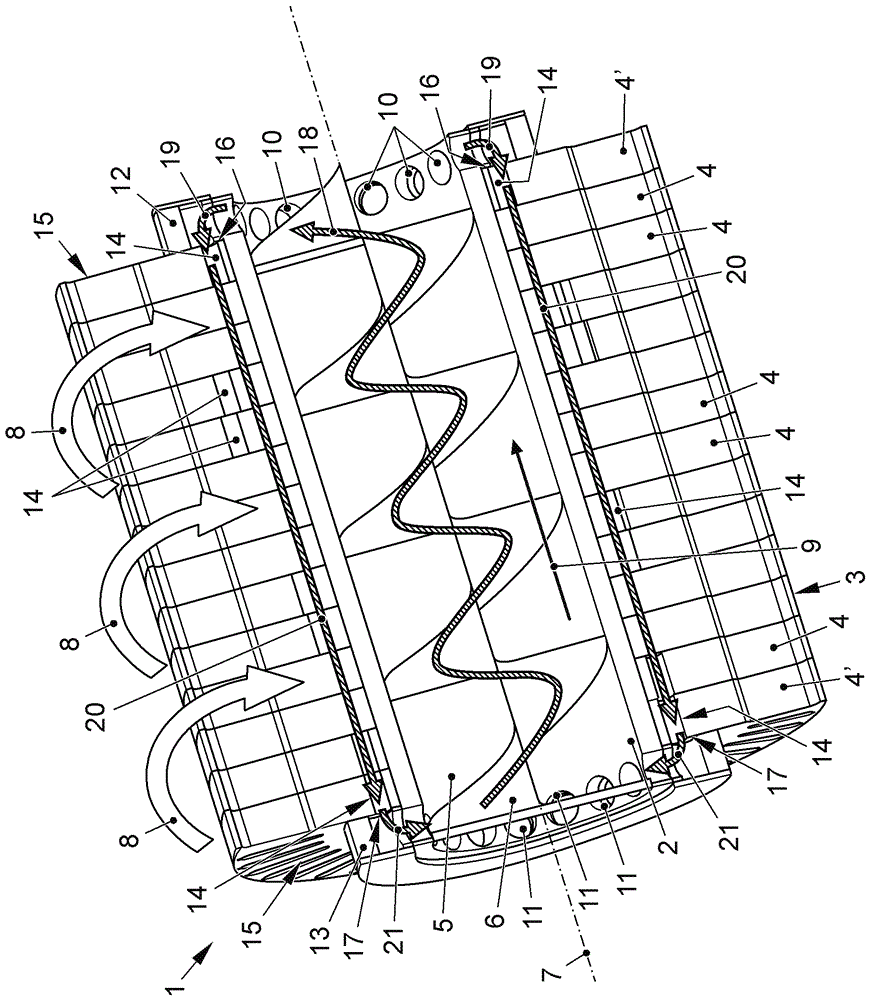

[0057] figure 1 and 2Different views of a rotor 1 for an electrical machine (not shown) with internal rotor cooling according to the invention are shown. The rotor 1 consists of a rotor shaft designed as a hollow shaft 2 and a rotor body 3 arranged on the rotor shaft in a rotationally fixed manner or connected thereto. The rotor body 3 is designed as a rotor lamination pack consisting of a plurality of rotor laminations 4 , 4 ′. In the inner space 5 of the hollow shaft 2 , the delivery spindle 6 is arranged in a rotationally fixed manner, in particular so as to be retracted into the hollow shaft 2 . During operation of the electric machine, the rotor body 3 , the hollow shaft 2 and the delivery spindle 6 jointly rotate about the axis of rotation 7 . This rotation is indicated by one or more directional arrows 8 .

[0058] In order to absorb the waste heat of the rotor 1 generated during the operation of the electric machine, a cooling fluid is provided which is guided or c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com