Gas stove

A technology of gas stove and fuel gas, which is applied in the direction of heating fuel, household appliances, household stove/stove, etc., which can solve the problems of fuel gas leakage and achieve the effect of suppressing false detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

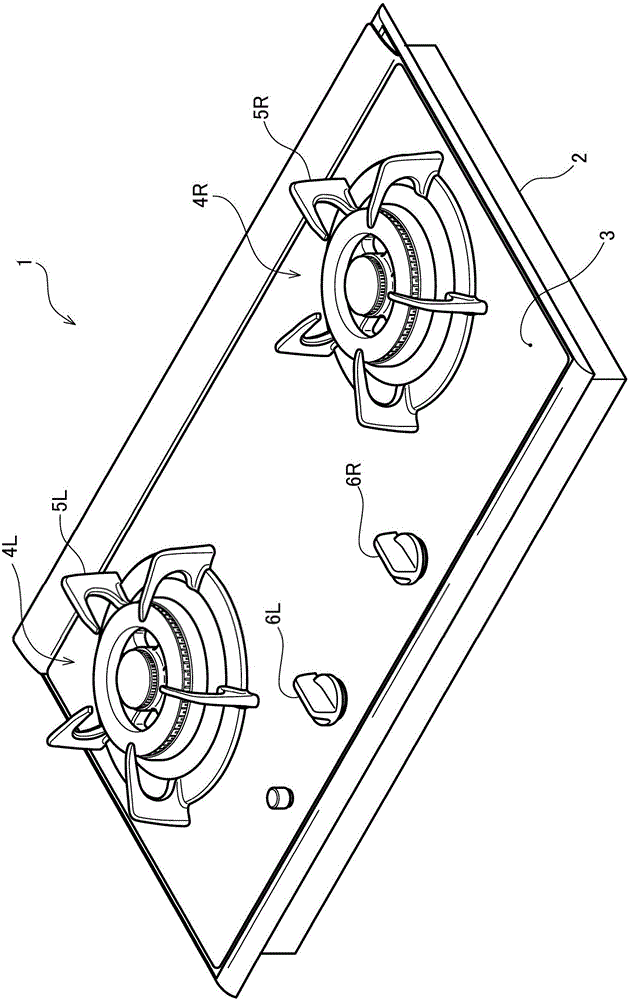

[0034] figure 1 It is a perspective view which shows the appearance of the gas stove 1 of this Example. The gas stove 1 of the present embodiment includes: a stove main body 2 formed in a thin box shape with an open upper surface side; a top plate 3 placed on the stove main body 2 and covering the upper surface of the stove main body 2 ; stove burners 4R, 4L, which are provided in such a way that their upper parts protrude from through holes formed in the top plate 3; For placing cooking containers such as pots.

[0035] In addition, on the top plate 3 , operation knobs 6R, 6L are provided corresponding to the stove burners 4R, 4L, respectively, and the operation knobs 6R, 6L are operated by the user when igniting, when adjusting the heating power, and the like. When the operation knobs 6R, 6L are pushed down and rotated in a predetermined direction (counterclockwise in this embodiment), fuel gas is supplied to the stove burners 4R, 4L and ignited by an unillustrated spark ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com