Outlet structure of pipeline of non-excavation type comprehensive pipe rack and method thereof

A comprehensive pipe gallery and non-excavation technology, applied in underwater structures, infrastructure engineering, water conservancy projects, etc., can solve problems such as high cost, large distance between working wells, and difficult to meet pipeline requirements, and improve construction efficiency , The effect of facilitating construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

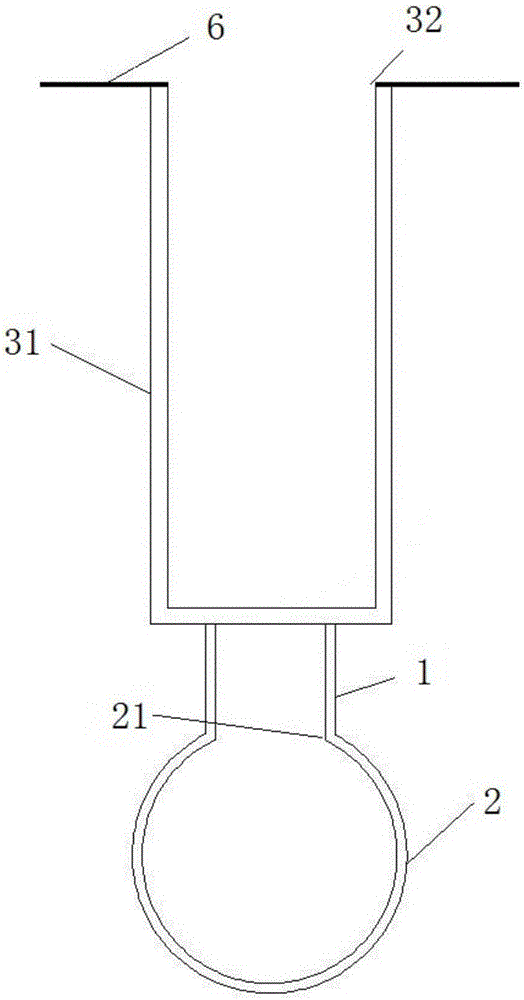

[0038] like figure 1 , 2 As shown in and 7, the outlet shaft is a shaft 3, the shaft 3 includes a shaft body 31, the first opening is a shaft lock 32 communicating with the ground 6, and the shaft lock 32 is connected to the shaft shaft The upper end of the body 31 is connected. When the comprehensive pipe gallery tunnel 2 is first constructed and penetrated, the second opening is opened on the side: the wellhead is excavated from the construction ground 6, and the shaft lock is constructed, and then excavated downwards, and the construction is carried out in sections along with the excavation. Initial support until the bottom cover; open the second opening on the top: to the top of the comprehensive utility tunnel 2 and reserve a certain safety distance; further, the shaft 3 also includes a transverse passage connected with the cable trench, and the transverse The passage is arranged at the upper end of the shaft shaft 31, and the transverse passage communicates with the sha...

Embodiment 2

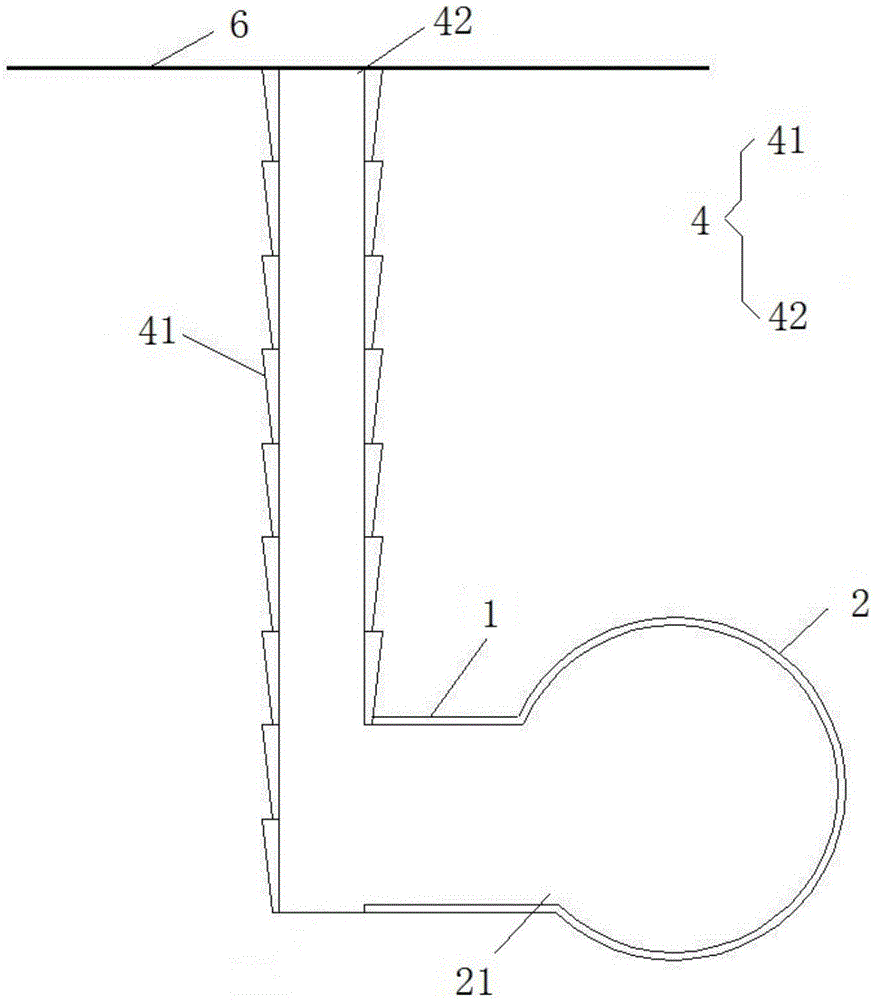

[0040] like image 3 , 4As shown in and 7, the outlet well is an artificial hole-digging pile 4, and the artificial hole-digging pile 4 includes a plurality of segmental reinforced concrete retaining walls 41, and the first opening is a transitional retaining wall 42 communicated with the ground 6, and a plurality of The segmental reinforced concrete retaining wall 41 is connected up and down sequentially, and the transitional retaining wall 42 is connected with the upper end of the segmental reinforced concrete retaining wall 41 at the top. When the comprehensive pipe gallery tunnel 2 is first constructed and penetrated, a second opening 43 is opened on the side: Excavate the wellhead from the construction ground 6, construct the shaft lock, excavate and sink in sections to form the retaining wall until the bottom seal; open the second opening at the top: excavate in stages and construct the retaining wall to the top of the comprehensive pipe gallery tunnel 2 and A certain s...

Embodiment 3

[0042] like Figures 5 to 7 As shown, the outlet well is an open cut working well 5, the open cut working well 5 includes a working well shaft 51, the first opening is a working well connecting section structure 52 communicating with the ground 6, and the working well The connecting section structure 52 communicates with the upper end of the working well shaft 51. After the comprehensive pipe gallery tunnel 2 is first constructed and penetrated, a second opening is opened on the side: the working well connecting section structure 52 is constructed on the ground 6, and the main structure or Directly adopt the caisson form; open the second opening at the top: to the top of the comprehensive utility tunnel 2 and reserve a certain safety distance; further, the open cut work shaft 5 also includes a transverse channel connected with the cable trench, so The transverse channel is arranged on the upper end of the working well body 51, and the transverse channel communicates with the w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com