Efficient mixing stirrer for molten iron desulphurization

A technology of mixing and stirring and molten iron desulfurization, which is applied in the field of molten iron pretreatment, can solve the problems of unbalanced rotation and stirring of agitators, reduce the speed of sticking slag, shorten the stirring time, etc. The effect of shearing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

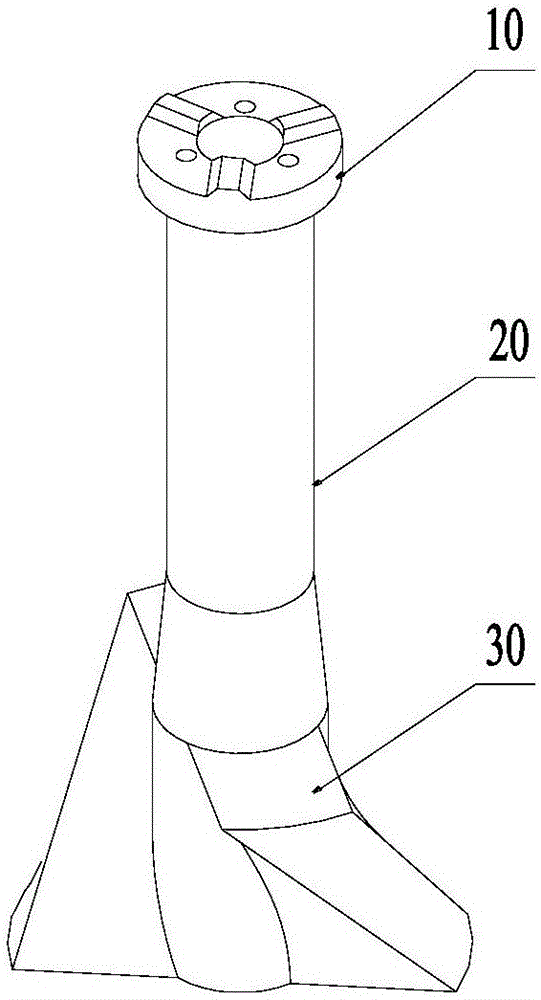

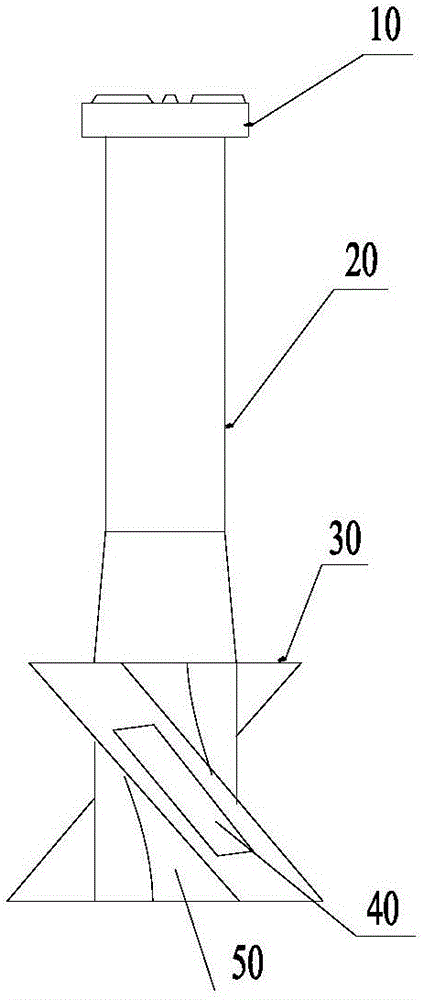

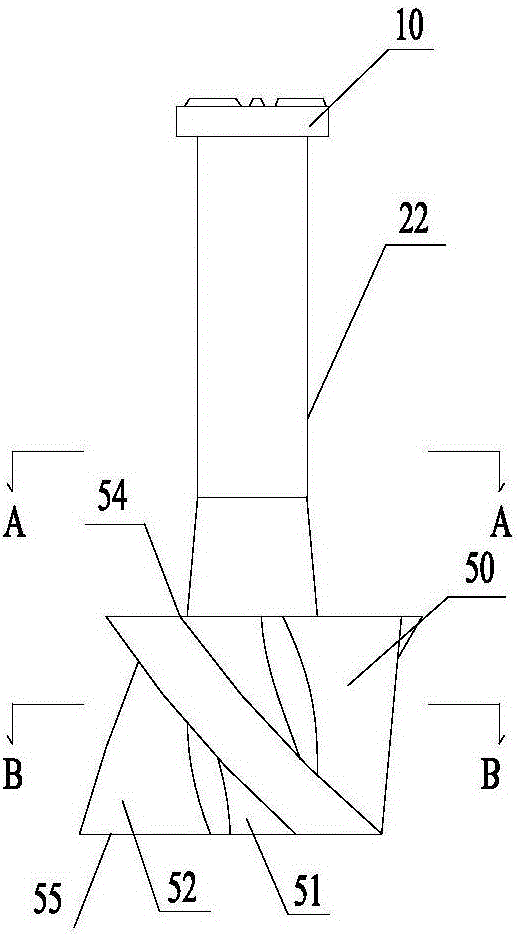

[0052]Two stirring blades 30 are evenly arranged around the circumference of the stirring shaft 20, and the refractory castable outer cylinder formed by extending vertically upward along the upper end surface of the outer circular platform of the refractory castable (that is, the bottom surface of the outer cylinder is the upper end surface of the outer circular platform, and the radius is the same Both are R1) circumference length, lead P1 and the length of the refractory castable outer cylindrical helix. The diagonal α of the lead P1 in the right triangle is 85-35°.

Embodiment 2

[0054] Three stirring blades 30 are uniformly arranged around the stirring shaft 20 in the circumferential direction, and the refractory castable outer cylinder formed by extending vertically upward along the upper end surface of the outer circular platform of the refractory castable (that is, the bottom surface of the outer cylinder is the upper end surface of the outer circular platform, and the radius is the same Both are R1) the circumference length, the lead P1 and the length of the refractory castable outer cylindrical helix. The diagonal α of the lead P1 in the right triangle is 75~45° or 70~55°, other content is the same as above content is exactly the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com