Non-mechanical-stirring sludge treatment anaerobic reactor and method for material circulation in reactor

An anaerobic reactor, sludge treatment technology, applied in biological sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. and other problems, to achieve the effect of harmless treatment, alleviation of environmental pressure, and difficult maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

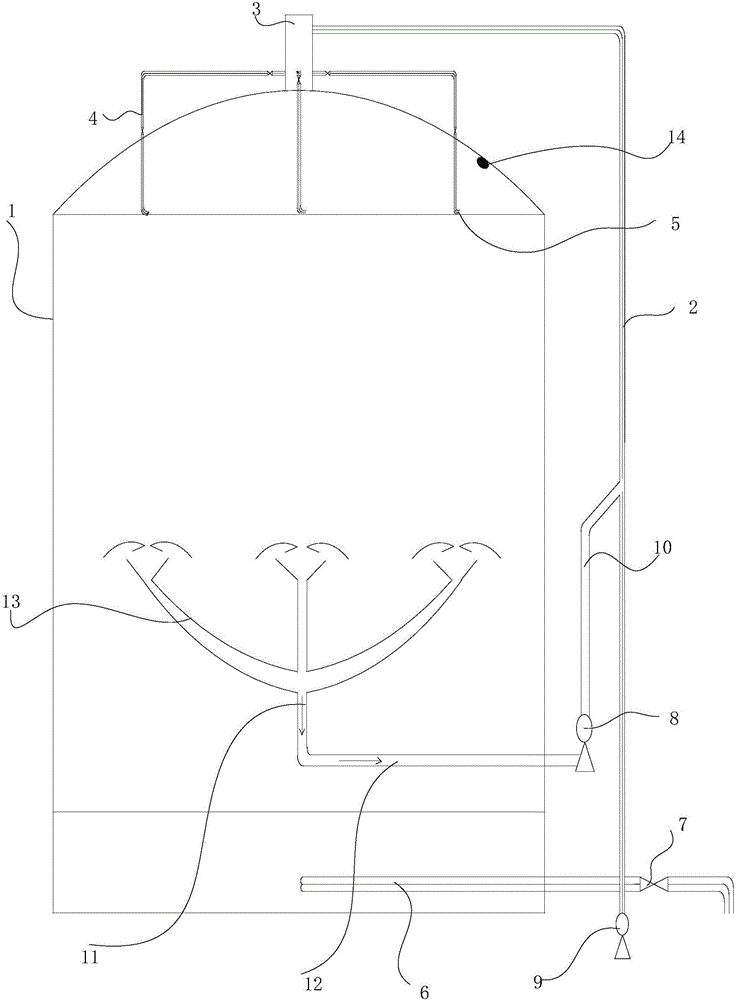

[0026] refer to figure 1 , the anaerobic reactor of the present invention includes a fermenter tank body 1, an inlet and outlet system, and a material circulation system; wherein, the inlet and outlet system includes a main feed pipe 2, a discharge pipe 6 connected to the bottom of the tank body 1, and a second A feeding pump 8, the first feeding pump 8 is used to pump external materials into the tank body 1 through the main feeding pipe 2; the top wall of the tank body 1 is provided with a feeding port, and the outlet of the main feeding pipe 2 The material end is connected with the feed port, so that the external material enters the tank body from the feed port at the top of the tank body 1; the material circulation system includes a material absorption main pipe arranged in the middle and lower part of the tank body 1, and a main The auxiliary feed pipe 10 connected by the feed pipe 2; the discharge end of the material absorption main pipe communicates with the auxiliary fe...

Embodiment 2

[0038] In addition, the present invention also proposes a method based on the material circulation in the above-mentioned anaerobic reactor, which can improve the circulation of the reaction material in the anaerobic reactor to ensure that the material is fully fermented, and can make full use of the organic waste generated by urban life, Especially domestic sludge.

[0039] It is achieved through the following steps:

[0040] Pump the pretreated reaction material from the top of the anaerobic reactor tank through the main feed pipe outside the anaerobic reactor, and when it reaches the specified height, stop feeding and start slag discharge. At this time, the second feed pump starts The material in the tank is continuously circulated at a certain flow rate;

[0041] When the liquid level in the reaction tank drops to a certain height, the slag discharge is stopped, and at the same time, the main feeding pipe and the auxiliary feeding pipe are fed to the designated height in ...

Embodiment 3

[0043] The method based on material circulation in the above-mentioned anaerobic reactor of the present embodiment, it comprises the steps:

[0044] First, pump the pretreated sludge into the anaerobic reactor tank from the top of the reactor tank through the main feed pipe. When the liquid level of the pumped material is 1.4 meters away from the tank top, the controller controls the feed valve and The first feed pump is turned off to stop feeding, and the discharge valve is controlled to open to discharge the discharge pipe and slag. At the same time, the second feed pump is controlled to open, and the second feed pump starts to circulate the material in the tank at a certain flow rate without interruption. ;

[0045] When the height of the liquid level in the tank detected by the liquid level detector is greater than or equal to 1.6 meters from the tank top, the controller controls the discharge valve to close to stop slag discharge, and at the same time controls the feed va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com