Monitoring device and method of axial force of shield tunnel joint bolt

A technology for shield tunneling and monitoring devices, which is used to measure torque/torsional force and other directions during tightening, which can solve the problem of extra bolt length and reserved installation space, difficulty in reducing the size of structural safety sensors, thickness of strain gauge pressure sensors, Large size and other problems, to achieve the effect of reduced thickness and size, wide application range, and meet the needs of bolt tightening force measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. This embodiment is carried out on the premise of the technical solution of the present invention, and detailed implementation and specific operation process are given, but the protection scope of the present invention is not limited to the following embodiments.

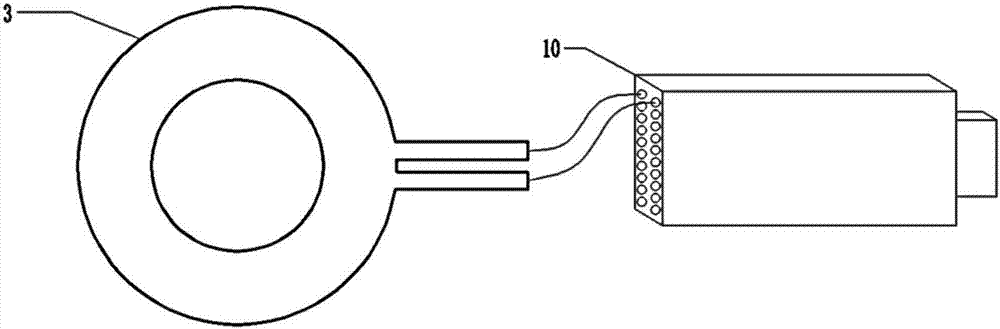

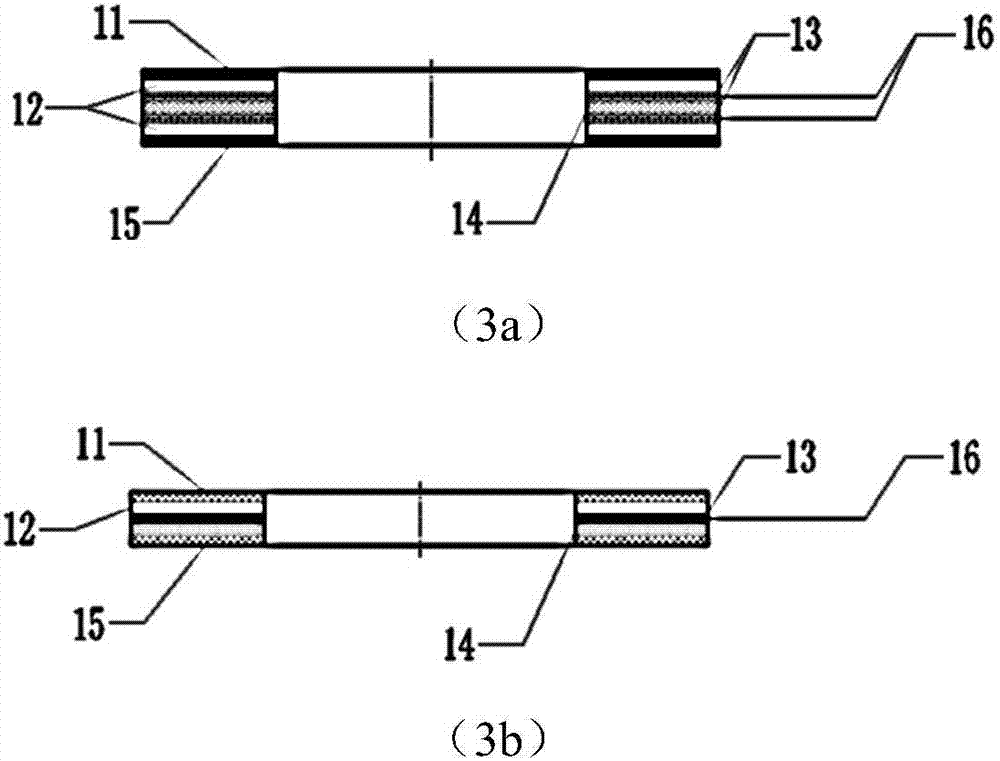

[0050] This embodiment provides a monitoring device and method for the axial force of the shield tunnel joint bolts. The monitoring device includes: a film type bolt axial force sensor 3, which is connected with the shield tunnel joint bolts and is used to withstand the shield tunnel joint bolts. The axial force is directly converted into an electrical signal; the signal processing device 10 is connected with the thin-film bolt axial force sensor 3 during monitoring, and is used to convert the electrical signal transmitted by the thin-film bolt axial force sensor 3 into a readable pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com