Construction engineering integrated 3D printing and building system and use method thereof

A 3D printing and construction engineering technology, which is applied in the direction of building construction, construction, and building material processing, can solve the problems that the 3D printing device cannot be used for deep foundation construction, and cannot realize the integrated printing and construction of the foundation and superstructure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

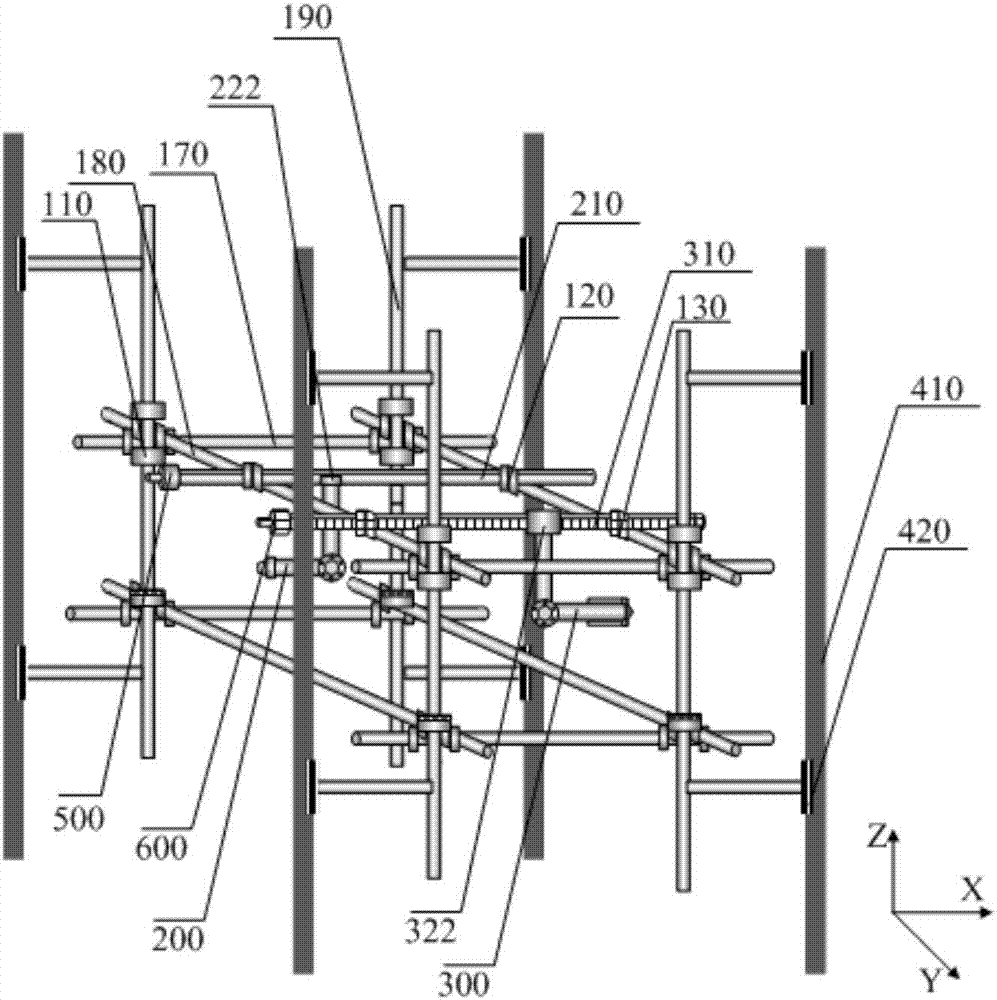

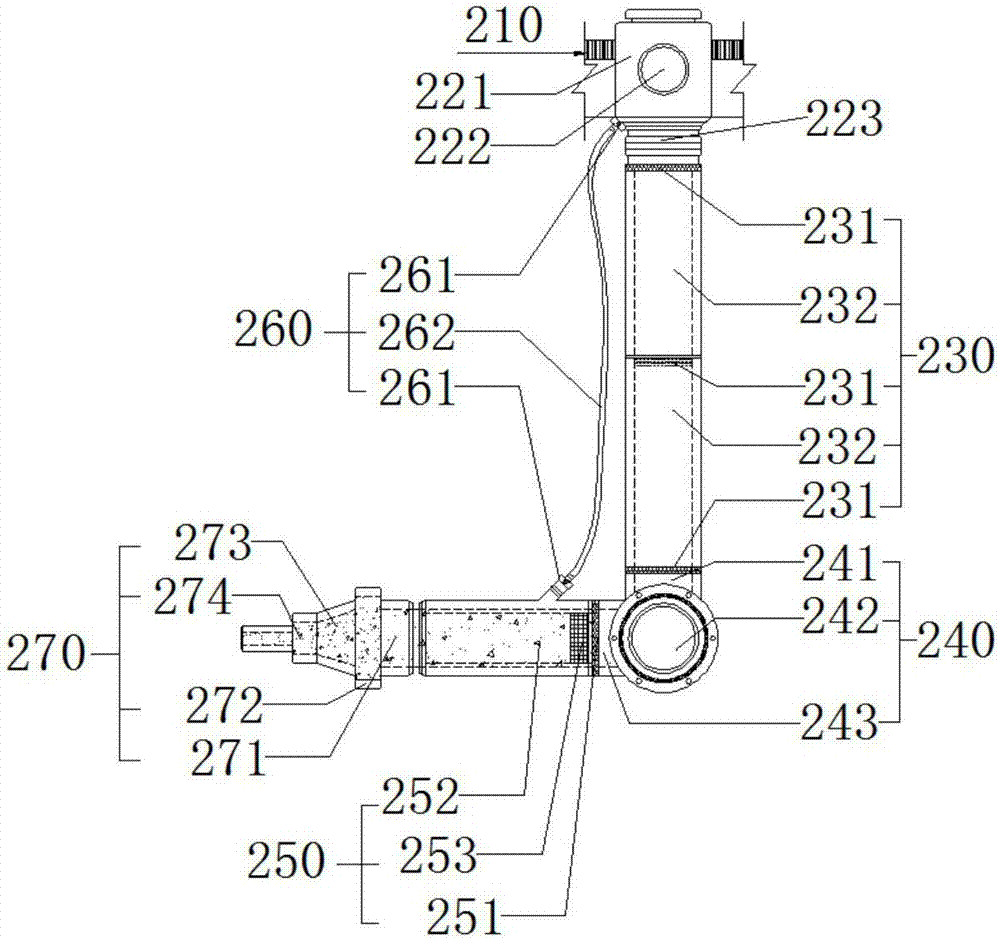

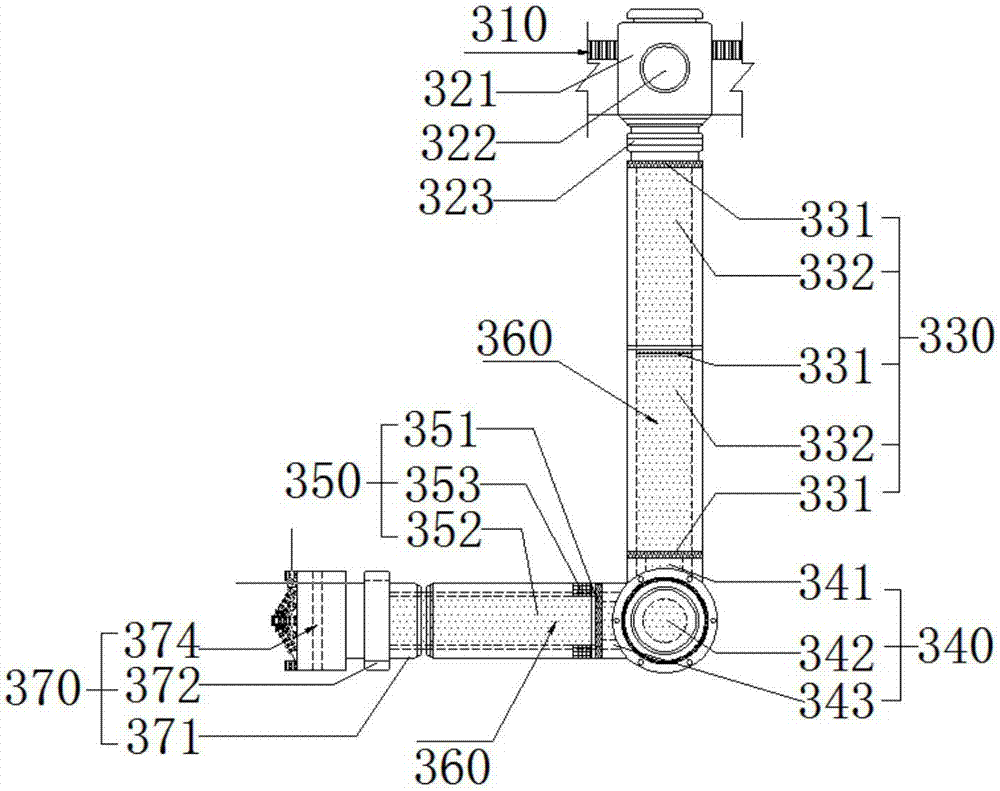

[0076] refer to figure 1 , a building engineering integrated 3D printing construction system in this embodiment, including a modular three-axis drive guide device 100, a flexible 3D printing head 200, a flexible excavation and soil removal device 300, and a lifting device 400;

[0077] The modularized three-axis drive guide device 100 includes, X-axis guide rail 170, Y-axis guide rail 180, Z-axis guide rail 190, print head guide rail beam 210, and excavation and soil removal device guide rail beam 310;

[0078] The X-axis guide rails 170 are connected with the Y-axis guide rails 180 in pairs to form an XY plane guide frame;

[0079] The Z-direction guide frame drive brake 110 is set on the Z-axis guide rail 190, and the end points of the XY plane guide frames are respectively connected with each Z-direction guide frame drive brake 110, and the XY plane guide frame is driven along the Z-axis guide rail 190 along with the Z-direction guide frame. Brake 110 moves;

[0080] The ...

Embodiment 2

[0106] The technical scheme of the method of using the construction engineering integrated 3D printing construction system of this embodiment is as follows:

[0107] A method for using a construction and engineering integrated 3D printing construction system, which is used for the construction of underground engineering, comprising the following steps:

[0108] refer to Figure 4 , the first step is to adjust the head 374 of the CNC tunneling and dumping machine to the vertical direction, and mill and excavate the ground layer by layer to form the cavity 911 of the first layer of enclosure structure, and the excavated soil and gravel pass through the soil and crushed Stone exit 600 is discharged;

[0109] refer to Figure 5 , the second step is to adjust the replaceable nozzle 274 to the vertical direction, and spray building materials layer by layer to the side wall of the first layer of enclosure structure cavity 911 from bottom to top to form the first layer of enclosure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com