Biological dispensing equipment

A batching equipment and biological technology, applied in the direction of biochemical equipment and methods, biomass post-treatment, biomass pre-treatment, etc., can solve the problems of difficult replacement and maintenance, unreasonable design, difficult assembly and manufacturing, etc., to improve uniformity, The effect of improving production efficiency and shortening batching time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

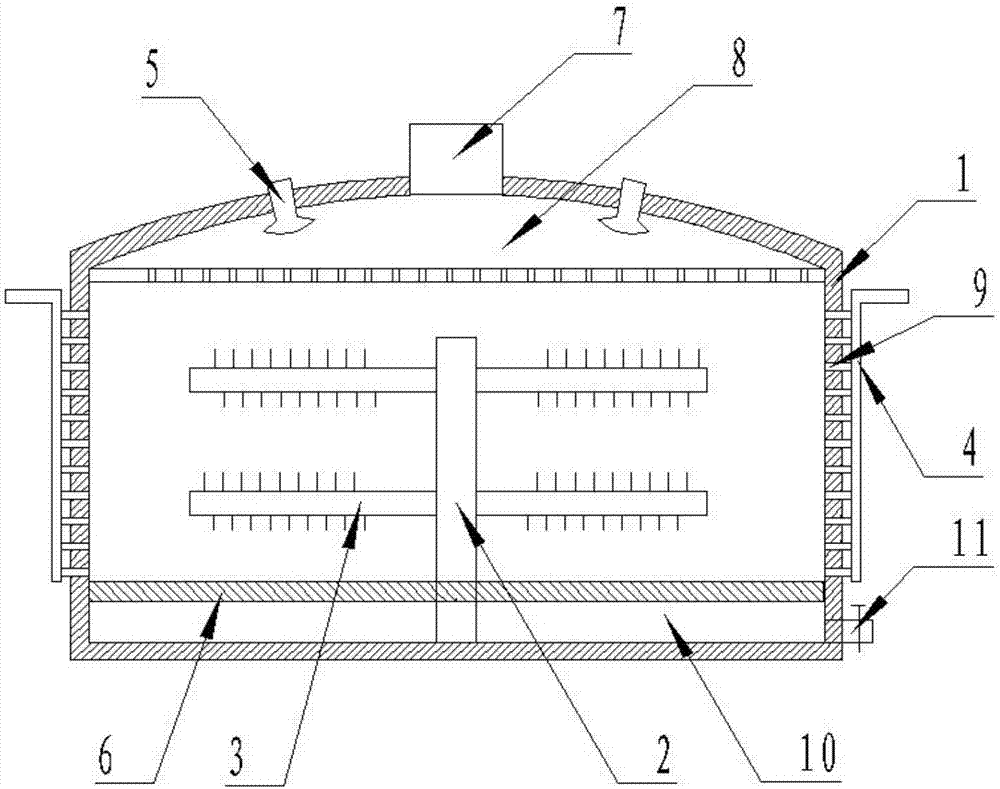

[0009] Such as figure 1 Shown, a kind of biological batching equipment, it comprises mixing tank 1, stirring shaft 2, stirring rod 3, water spray pipe 4, blowing pipe 5 and filter sieve body 6, the top of mixing tank 1 is provided with a decomposing enzyme inlet 7 A blowpipe 5 is evenly arranged on the top of the mixing cylinder 1, and the blowpipe 5 communicates with the inside of the mixing cylinder 1, and a fermentation gas mixing chamber 8 is arranged on the top of the mixing cylinder 1, and the fermentation gas mixing chamber 8 is connected to the mixing cylinder. The inside of the body 1 is connected, and the filter sieve body 6 is arranged on the bottom of the mixing cylinder body 1, and the stirring shaft 2 is arranged at the bottom of the mixing cylinder body 1, and the stirring shaft 2 is provided with a stirring rod 3 in the left and right direction, and at the bottom of the mixing cylinder body 1 Water spray ports 9 are provided on both sides, and the water spray p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com