High-temperature-resistant desulfurizer for oil-gas field and preparation method of desulfurizer

A technology for desulfurization agent and oil and gas fields, applied in the petroleum industry, gas fuel, fuel, etc., can solve the problems of low desulfurization efficiency, and achieve the effects of high desulfurization efficiency, high product cost performance, and simple synthesis process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

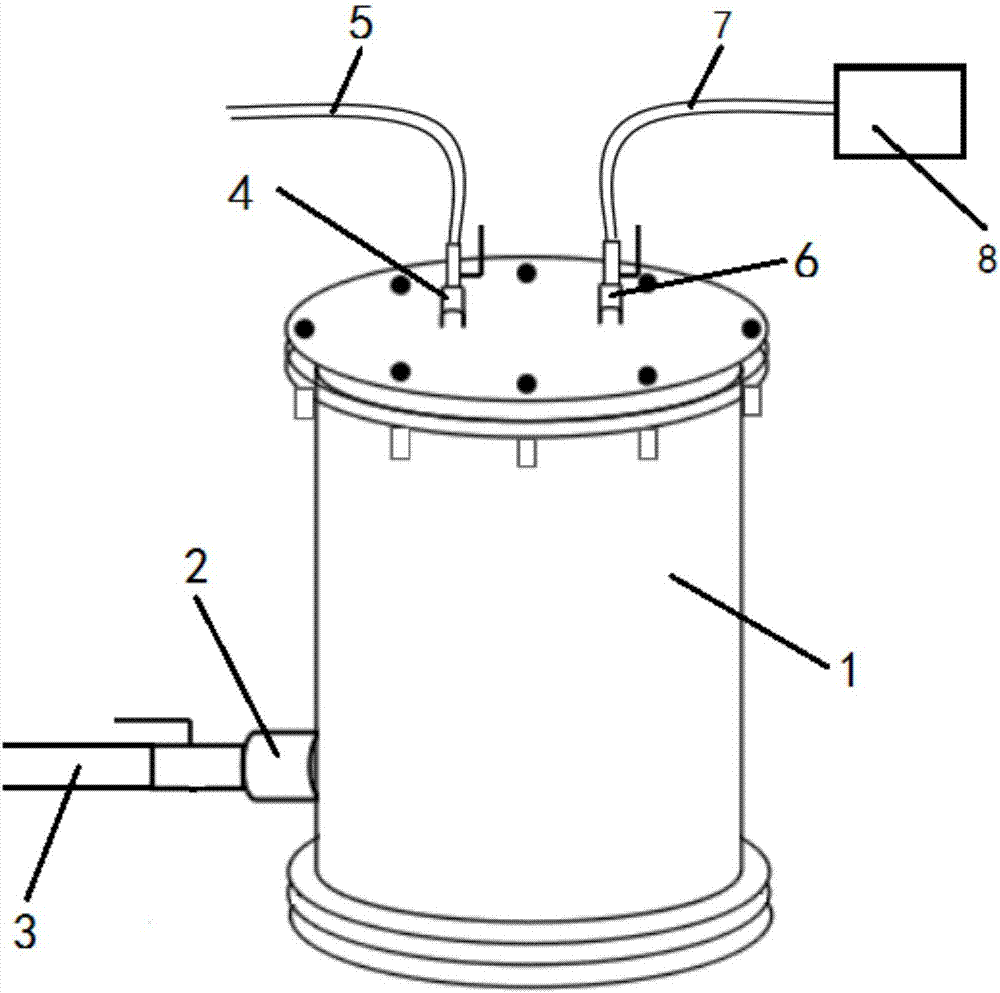

Image

Examples

preparation example Construction

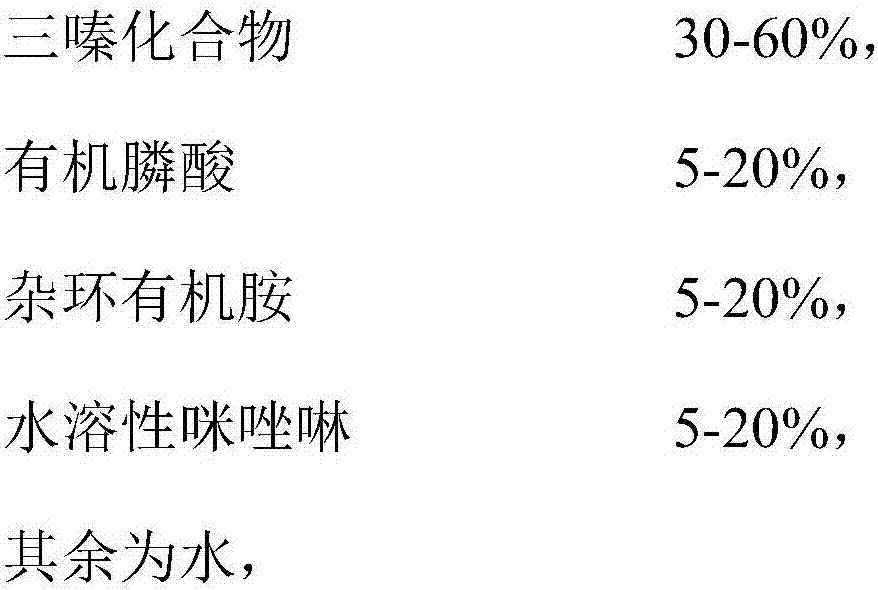

[0039] The invention provides a method for preparing a high-temperature-resistant desulfurizer for oil and gas fields, and its specific operation steps are as follows:

[0040] Step 1, the preparation of triazine compound

[0041] 1.1 Add polyethylene polyamine into the container, start stirring, and add formaldehyde condensate into polyethylene polyamine while stirring. Since formaldehyde condensate is added to polyethylene polyamine, aldolamine condensation reaction will occur, which is an exothermic reaction. In order Control the temperature of the mixture in the container at 60°C to 65°C, and add the formaldehyde condensate in batches; after the formaldehyde condensate is added, stir evenly to obtain mixture A;

[0042] 1.2 Continue to stir the mixture A. If the temperature of the mixture A is lower than 60°C, keep the temperature of the mixture A at 60°C~65°C by heating; under the condition of stirring, keep the mixture A at a temperature of 60°C~65°C for 2.5 ~3.5 hours,...

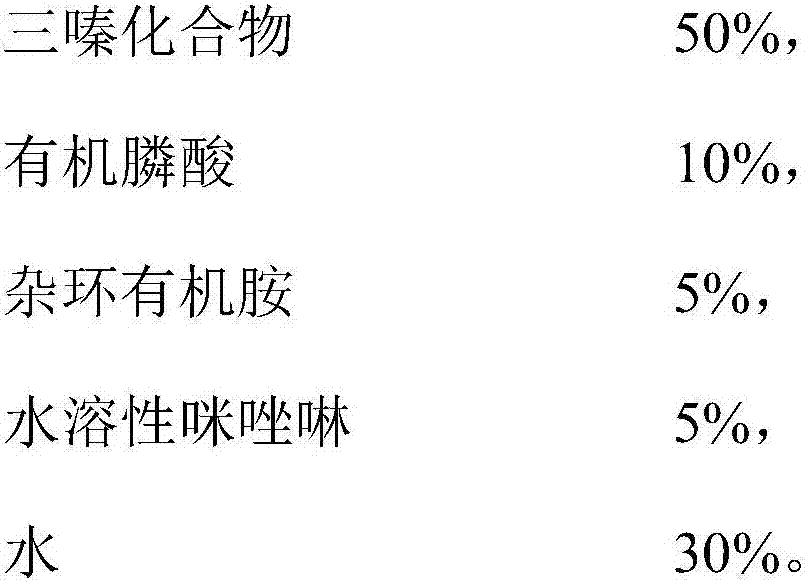

Embodiment 1

[0062] A method for preparing a high-temperature-resistant desulfurizer for oil and gas fields, the specific steps of which are as follows:

[0063] Step 1, the preparation of triazine compound

[0064] 1.1 Add 180g of diethylenetriamine into the four-necked flask, connect the feed liquid dropper and the electric stirrer; the electric stirrer starts stirring at a speed of 65rpm / min, and add methylal into the diethylenetriamine while stirring , since the aldolamine condensation reaction will occur when methylal is added to diethylenetriamine, it is an exothermic reaction. In order to control the temperature of the mixture in the four-necked flask and keep it at 60°C, add formaldehyde in four batches through the feed liquid dropper. For acetal, add 30g of methylal in each batch; after all 120g of methylal is added, stir evenly to obtain mixture A;

[0065] 1.2 The electric stirrer continues to stir mixture A at a speed of 65rpm / min. If the temperature of mixture A is lower than...

Embodiment 2

[0074] A method for preparing a high-temperature-resistant desulfurizer for oil and gas fields, the specific steps of which are as follows:

[0075] Step 1, the preparation of triazine compound

[0076] 1.1 Add 300g of triethylenetetramine into a four-necked flask, connect the feed liquid dropper and electric stirrer; the electric stirrer starts stirring at a speed of 58rpm / min, and add methylal to triethylenetetramine while stirring , since methylal is added to triethylenetetramine, an aldolamine condensation reaction will occur, which is an exothermic reaction. In order to control the temperature of the mixture in the four-necked flask and keep it at 62°C, add formaldehyde in five batches through the feed liquid dropper. For acetal, add 40g of methylal in each batch; after all 200g of methylal is added, stir evenly to obtain mixture A;

[0077] 1.2 The electric mixer continues to stir the mixture A at a speed of 58rpm / min. If the temperature of the mixture A is lower than 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com