Insulator material, insulator and preparation method

A technology of insulators and raw materials, applied in the field of composite material preparation, can solve problems such as easy accumulation of large surface charges along the surface, distortion of electric field on the surface of basin-type insulators, flashover, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A method for preparing the above-mentioned insulator material according to an embodiment is also provided, including the following steps S1-S2.

[0035] Step S1: mixing the raw materials of the insulator material to obtain a base material.

[0036] In one of the embodiments, the step of pulverizing and drying each raw material is also included. Specifically, the step of pulverizing and drying the micron silicon carbide filler and the nanometer silicon carbide filler is also included, so as to avoid the influence of residual moisture in the filler particles on the performance of the final base material. Preferably, the drying condition is drying at 80-100° C. for 12-24 hours. More preferably, the drying condition is drying at 100° C. for 12 hours.

[0037]In one embodiment, step S1 includes the following steps: adding micron silicon carbide fillers, nanometer silicon carbide fillers, and a curing agent to the epoxy resin in sequence under stirring conditions, and mixin...

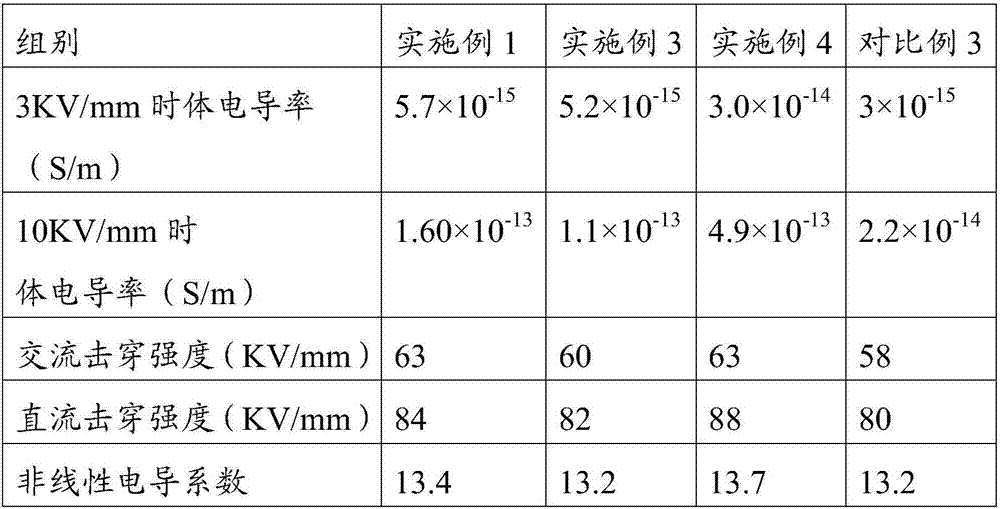

Embodiment 1

[0051] An insulator material, the raw material of which is mainly composed of 100 parts of epoxy resin, 30 parts of curing agent, 10 parts of micron silicon carbide filler, and 10 parts of nanometer silicon carbide filler. The epoxy resin is glycidyl ether bisphenol A epoxy resin; the curing agent is polyamide resin HY-651; the particle size of the micron silicon carbide filler is 30 μm, and the particle size of the nano silicon carbide is 50 nm. Among them, the micron silicon carbide filler and the nanometer silicon carbide filler are β-type silicon carbide provided by Hengxin Silicon Carbide Powder Co.Ltd.

[0052] The insulating material is made into an insulator, including the following steps:

[0053] Both the micron silicon carbide filler and the nanometer silicon carbide filler were ground and pulverized, and then both were dried at 100° C. for 12 hours.

[0054] Under the condition of stirring, add micron silicon carbide filler into the epoxy resin, continue to stir f...

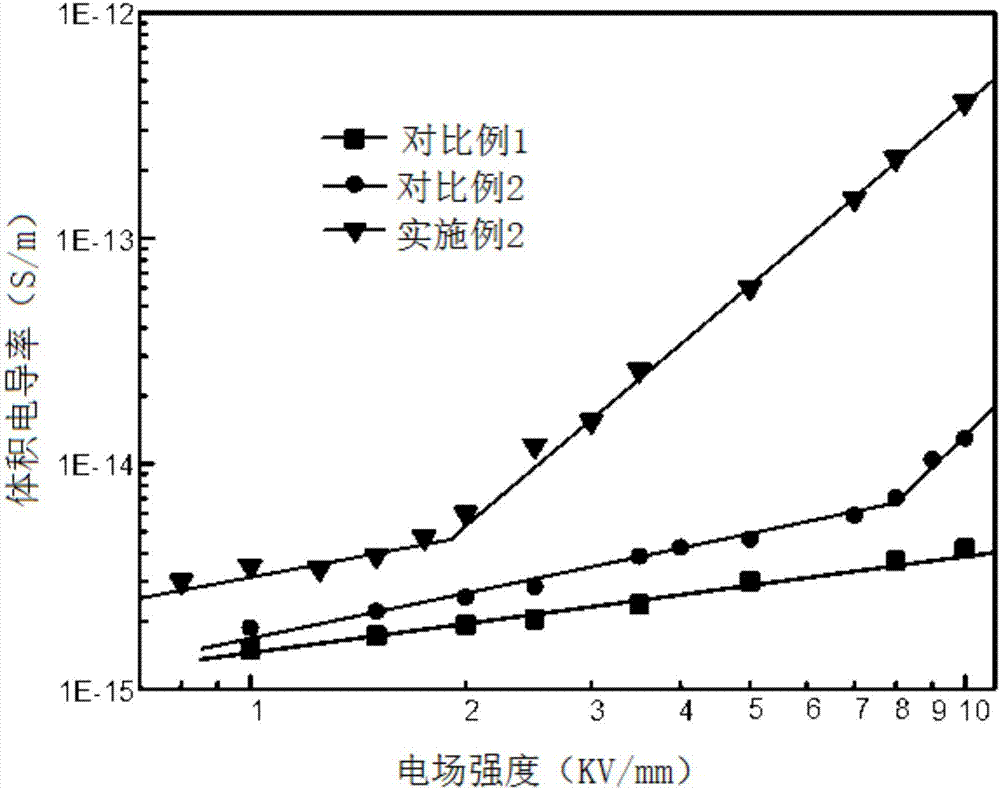

Embodiment 2

[0058] Embodiment 2 is basically similar to the insulator material and preparation method thereof in Embodiment 1, except that the number of parts of micron silicon carbide filler and nanometer silicon carbide filler is 30 parts, wherein the curing agent is phthalic anhydride, micron The particle size of the silicon carbide filler is 50 μm, and the particle size of the nano-silicon carbide is 80 nm. The degassing condition of the base material is degassing at 25°C for 2 hours, and then degassing at 55°C for 1 hour; the curing condition is curing at 60°C for 5 hours, and then curing at 140°C for 4.5 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com