Anti-static rubber and preparation method thereof

An antistatic and antistatic agent technology, applied in the field of rubber roller manufacturing, can solve problems such as poor heat generation, poor physical properties, and insufficient antistatic effect, and achieve improved wear resistance, high Green strength, good stretch and hardness effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

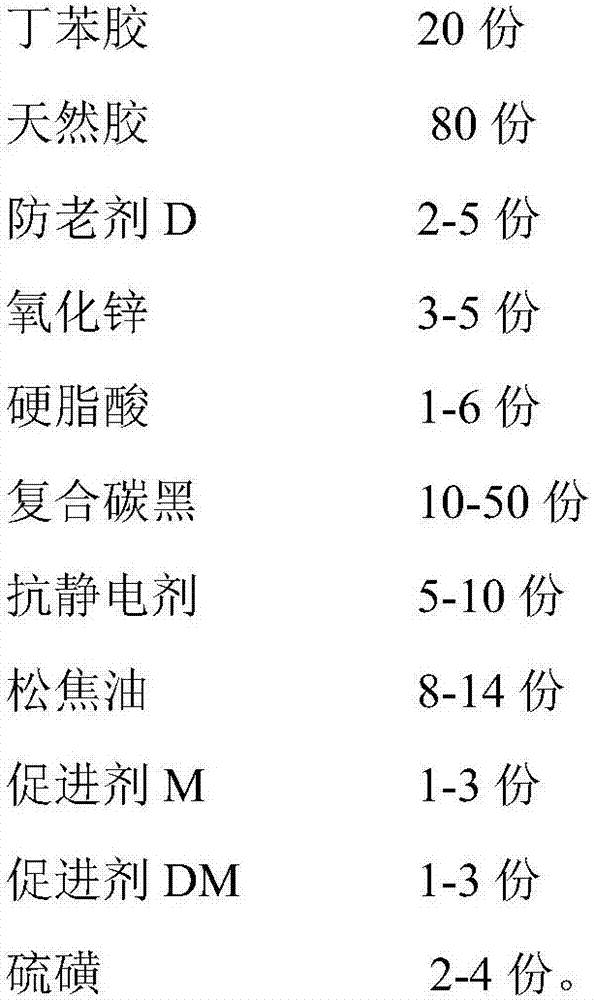

[0036] A kind of antistatic rubber, component and mass parts are as follows:

[0037]

[0038]

[0039] Described stearic acid is stearic acid 1801, stearic acid 1837 or stearic acid 1842. Its stearic acid uses animal fat as the main raw material. Furthermore, the composite carbon black is compounded from conductive carbon black, carbon black N330 and carbon black N774, and the ratio of parts by mass is (1-3):2:(1-3). The proportion used here is 1:2:1. N774 is suitable for all kinds of rubber with large particle size. The product particle size is 80-170nm and carbon black with low structure. It is mostly used for the buffer layer and ply rubber of tire carcass. , rubber hose, extruded products, various industrial rubber products, and wires, cables, etc., N774 can be filled in a large amount in the rubber without affecting the vulcanization characteristics of the rubber too much. The vulcanized rubber has high elongation, low heat generation, and high elasticity. , Good a...

Embodiment 2

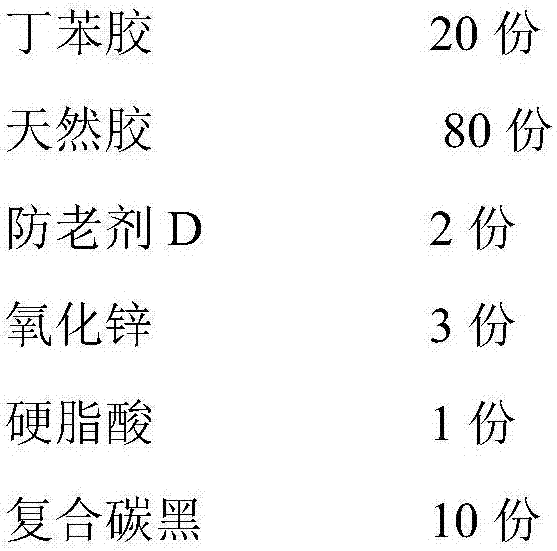

[0051] A kind of antistatic rubber, component and mass parts are as follows:

[0052]

[0053] Described stearic acid is stearic acid 1801, stearic acid 1837 or stearic acid 1842. Its stearic acid uses animal fat as the main raw material. The composite carbon black is compounded from conductive carbon black, carbon black N330 and carbon black N774, and the ratio of parts by mass is 3:2:3. N774 is suitable for all kinds of rubber, with large particle size, product particle size of 80-170nm, and low structure carbon black varieties. It is mostly used for buffer layer and ply rubber of tire carcass, rubber hose, extruded products, and various industrial rubber Products, as well as wires, cables, etc., N774 can be filled in a large amount in the rubber without affecting the vulcanization properties of the rubber too much. The vulcanized rubber has high elongation, low heat generation, high elasticity, and good aging resistance. The composite carbon black is acetylene carbon b...

Embodiment 3

[0057] Based on embodiment 1 or 2, embodiment 3 can also add high styrene resin therein to improve hardness, the mass fraction of addition ratio and conductive carbon black is 1:1, every time adding 1 part of high styrene resin rubber hardness improves about 1 Spend.

[0058] High styrene resins have a styrene content of 70%-90%. High styrene rubber is a special variety of styrene-butadiene rubber. It is latex produced by copolymerization of butadiene and styrene emulsion, then coagulated, washed, extruded and dehydrated, and dried to obtain the product. The styrene content in general styrene-butadiene rubber is 23.5 % ± 1%, the content is as high as 40% or more called high styrene rubber, combined with styrene 70% -90% is called high styrene resin. In this scheme, high styrene resin is used as a rubber additive for rubber production, which can improve the modulus, strength, hardness, tear resistance, flexion resistance and wear resistance of rubber, and the shape is about 3m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com