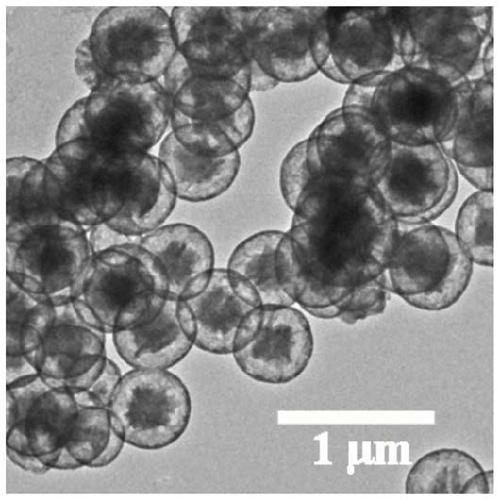

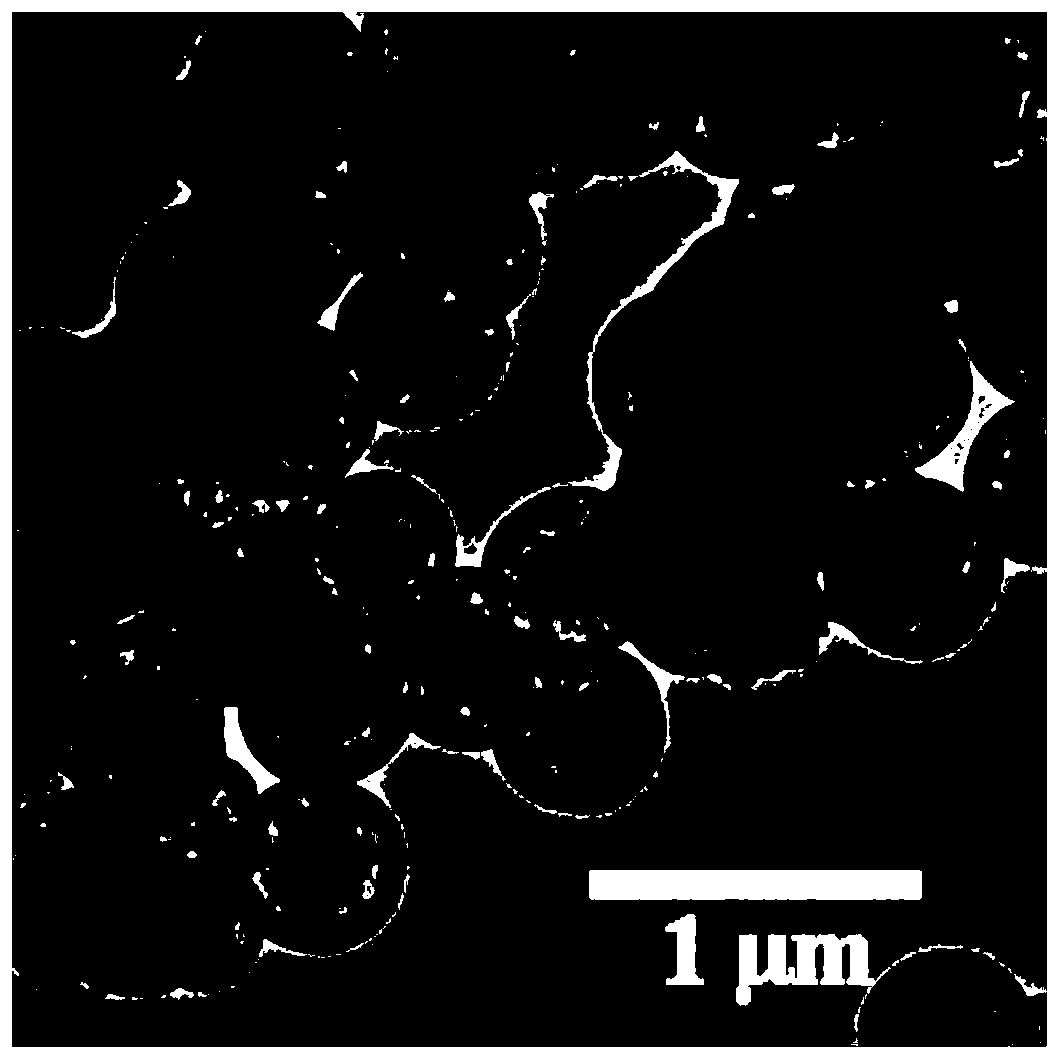

A kind of silicon dioxide egg yolk-eggshell structure material containing large spacing flower-shaped core and its preparation method

A technology of silicon dioxide and structural materials, applied in the direction of silicon dioxide, silicon oxide, chemical instruments and methods, etc., can solve the problem that the smooth surface is not conducive to loading or controlled release of guest molecules, is not conducive to increasing the specific surface area of materials, etc. The process is not easy to control and other problems, to achieve the effect of easy implementation of process operation, novel structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] As introduced in the background technology, the preparation method of the silicon dioxide material with egg yolk-eggshell structure in the prior art has certain deficiencies. In order to overcome the deficiencies of the prior art, the present invention provides a flower-shaped The preparation method of inner silicon dioxide egg yolk-eggshell structure comprises the following steps:

[0043] (1) Cetyltrimethylammonium bromide (CTAB) and polyvinylpyrrolidone (PVP) are fully dissolved in water and ethanol mixed solution, and it is formed into a transparent and uniform solution by stirring;

[0044] Wherein, the stirring temperature is 25-40° C., and the stirring speed is 400-600 r / min.

[0045] The molar ratio of CTAB and PVP is 1:(0.028-0.065).

[0046] The addition ratio of the CTAB, water and ethanol is 1 g: (300-320) mL: (180-200) mL.

[0047] (2) Ultrasonic dispersion of tetraethyl orthosilicate (TEOS) in cyclohexane;

[0048] Wherein, the addition amount ratio of ...

Embodiment 1

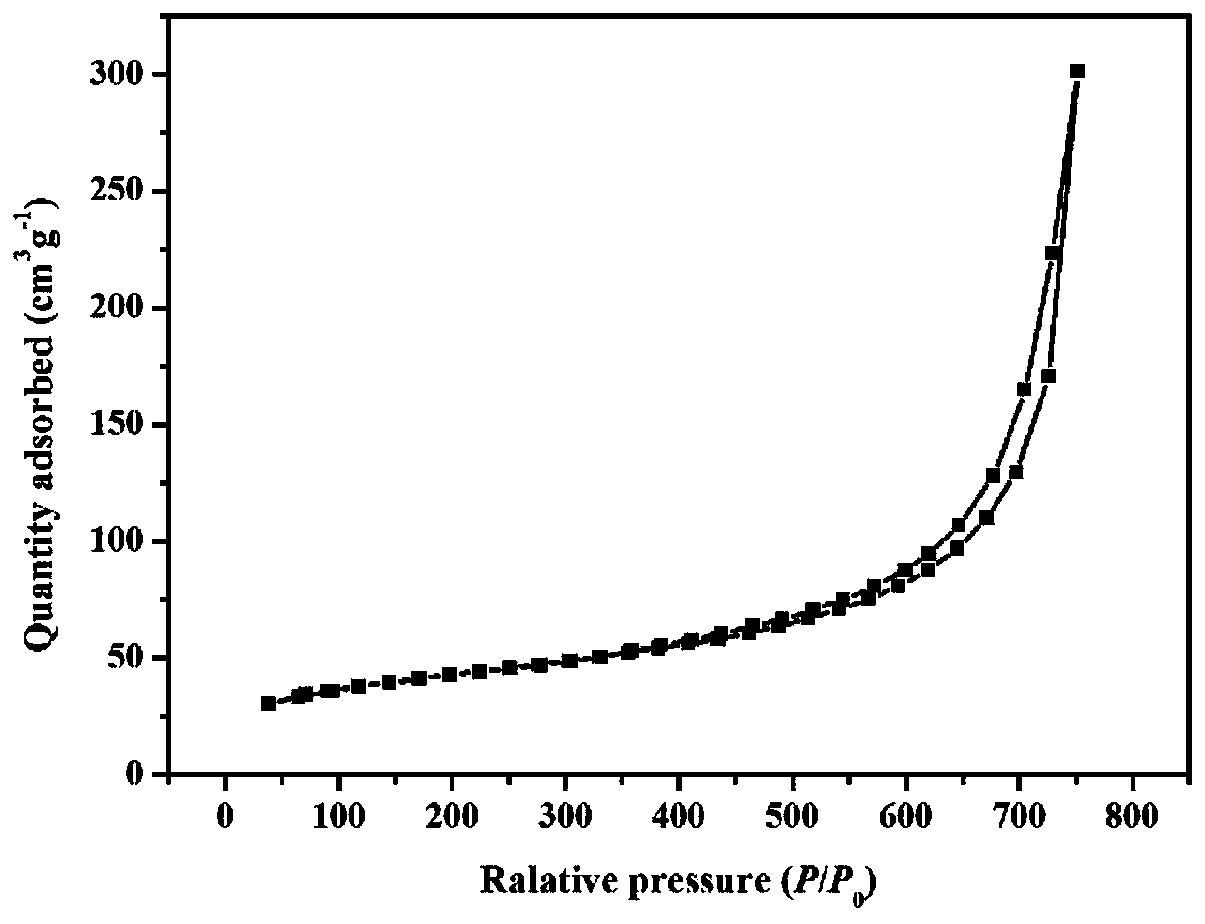

[0058] Add 0.08g CTAB and 0.4g PVP into a 100mL beaker and place it on a magnetic stirrer, add 25mL deionized water and 15mL ethanol to raise the temperature to 35°C, adjust the rotation speed to 500r / min to completely dissolve and form a uniform solution; gTEOS was ultrasonically dispersed in 3mL cyclohexane solution and the mixture was quickly added to the above solution under stirring, and 0.6mL ammonia water with a mass concentration of 23%-25% was added to the solution, followed by stirring reaction for 4h. The obtained white suspension was transferred to a 100mL reaction kettle, and placed in a thermostat at 160°C for 24h. After cooling, the white precipitate was filtered, and the obtained precipitate was repeatedly filtered and washed with distilled water. The obtained precipitate was dried at 55° C. for 10 h, and then the precipitate was calcined in a tubular calciner at 550° C. for 4 h to obtain a silica yolk-eggshell structure containing a flower-like core with large...

Embodiment 2

[0061] Add 0.08g CTAB and 0.4g PVP into a 100mL beaker and place it on a magnetic stirrer, add 25mL deionized water and 15mL ethanol to raise the temperature to 35°C, adjust the rotation speed to 500r / min to completely dissolve and form a uniform solution; The gTEOS was ultrasonically dispersed in 5 mL of cyclohexane solution and the mixture was quickly added to the above solution under stirring, and 0.6 mL of ammonia water with a mass concentration of 23%-25% was added to the solution, followed by a stirring reaction for 4 h. The obtained white suspension was transferred to a 100mL reaction kettle, and placed in a thermostat at 160°C for 24h. After cooling, the white precipitate was filtered, and the obtained precipitate was repeatedly filtered and washed with distilled water. The obtained precipitate was dried at 55°C for 10 hours, and then calcined in a tubular calciner at 550°C for 4 hours to obtain a silica egg yolk-eggshell structure with a flower-like core at large inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com