A kind of microspherical hollow structure nickel-based hydrogenation catalyst and preparation method thereof

A hydrogenation catalyst, spherical technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, preparation of organic compounds, etc., can solve destructive, environmental pollution, reduce material integrity and mechanical Strength and other issues, to achieve the effect of large internal cavity, simple preparation technology, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

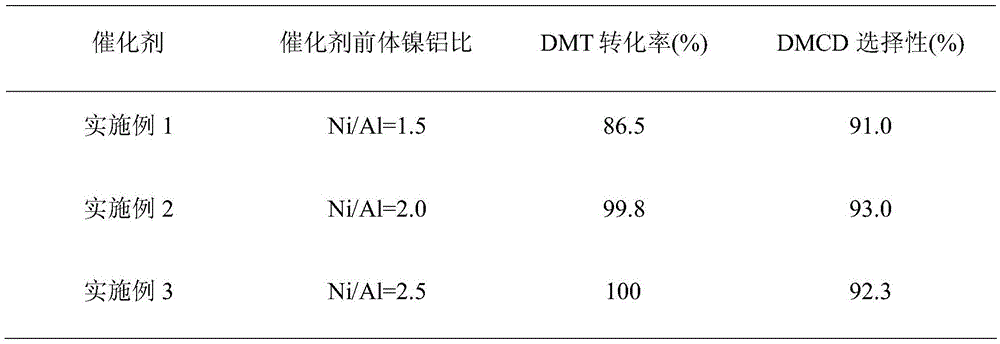

Examples

Embodiment 1

[0015] Weigh 1.2716g of Al(H 2 PO 4 ) 3 Dissolve in 40mL deionized water, then sonicate to completely dissolve into a clear and clear solution, reflux and stir in an oil bath at 90°C for 6 hours to obtain a white turbid colloidal solution, then pour it into the polytetrafluoroethylene liner of the high-pressure hydrothermal reactor; Weigh 0.9608g urea and 2.1028g NiSO 4 ·6H 2 O was dissolved in 40mL of deionized water, then sonicated to completely dissolve into a clear solution, poured into the PTFE liner of the above high-pressure hydrothermal reactor, stirred evenly and sealed, moved to a constant temperature oven at 100℃, reacted for 12h Take it out and cool it to room temperature; wash with deionized water and absolute ethanol to neutrality, and place the resulting product in a 70°C constant temperature drying oven for 48 hours to obtain a micron-sized hollow spherical nickel-aluminum hydrotalcite assembly material.

Embodiment 2

[0017] Weigh 0.9853g aluminum sec-butoxide and dissolve it in 40mL deionized water, sonicate it to completely dissolve into a transparent clear solution, reflux and stir in an oil bath at 100°C for 4h to obtain a white turbid colloidal solution, then pour it into a high-pressure hydrothermal reactor for polymerization In the tetrafluoroethylene liner; weigh 1.9216g urea and 3.1542g NiSO 4 ·6H 2 O was dissolved in 40mL deionized water, and ultrasonic washer was sonicated until it was completely dissolved to obtain a green transparent solution. This solution was transferred to the aforementioned inner tank and stirred until it was evenly mixed. The high-pressure hydrothermal kettle was sealed and moved to 150℃. In a constant temperature oven, after reacting for 12 hours, take it out and cool to room temperature; wash with deionized water and absolute ethanol to neutrality, and place the product in a constant temperature drying oven at 70°C for 48 hours to obtain a micron-sized holl...

Embodiment 3

[0019] Weigh 2.6657g of Al 2 (SO 4 ) 3 ·18H 2 O was dissolved in 40mL deionized water, sonicated to completely dissolve into a clear and clear solution, refluxed in an oil bath at 70°C and stirred for 4h. After the reaction, it was cooled to room temperature and transferred to a 100mL high-pressure hydrothermal reactor polytetrafluoroethylene liner Medium for use; then weigh out 2.2430g hexamethylenetetramine and 4.2056g NiSO 4 ·6H 2 Dissolve O in 40mL deionized water, sonicate it in an ultrasonic scrubber until it is completely dissolved, and obtain a green clear solution. Move it to the inner tank described before and stir it evenly; seal the high-pressure hydrothermal kettle and place it in a 140℃ constant temperature oven Reaction for 24h; after the reaction, take out the reaction kettle and cool it to room temperature, wash with deionized water and absolute ethanol until the pH of the system is about 7, and then dry the obtained precipitate in a constant temperature drying o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com