A method for preparing table tennis racket by adopting hsm molding process

A table tennis racket and molding process technology, which is applied in the field of fiber composite molding, can solve problems such as inconsistent bonding force between layers, increase equipment investment, and stress concentration, and achieve improved bonding force between layers, product yield, and good dimensional accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the preparation of table tennis racket

[0027] In the first step, put the heat self-expanding high-energy adhesive HR-330, which can be molded and preformed, into the core material mold of the product and tighten the mold, heat at 80°C for 15 minutes, and expand slightly. The volume ratio before and after the expansion is 1.1, filling the mold Cavity, cooling, obtains the prefabricated core material of table tennis racket;

[0028] The second step is to wrap three layers of carbon fiber prepreg cloth on the outside of the prefabricated core material of the table tennis racket to obtain the prefabricated body of the table tennis racket, put it into the molding mold and tighten the mold, and heat to 150°C for 30 minutes; at this time, the internal heat self-expands After being heated, the high-energy adhesive will generate an expansion force from the inside out. At the same time, the carbon fiber prepreg is solidified and formed, and the table tennis racket...

Embodiment 2

[0031] Embodiment 2: the preparation of table tennis racket

[0032] In the first step, put the heat self-expanding high-energy adhesive HR-313, which can be molded and preformed, into the core material mold of the product and tighten the mold, heat at 100°C for 3 minutes, and expand slightly. The volume ratio before and after the expansion is 1.01, and the mold is filled Cavity, cooling, obtains the prefabricated core material of table tennis racket;

[0033] The second step is to wrap three layers of carbon fiber prepreg cloth on the outside of the prefabricated core material of the table tennis racket to obtain the prefabricated body of the table tennis racket, put it into the molding mold and tighten the mold, and heat to 180°C for 10 minutes; at this time, the internal heat self-expands After being heated, the high-energy adhesive will generate an expansion force from the inside out. At the same time, the carbon fiber prepreg is solidified and formed, and the table tennis r...

Embodiment 3

[0036] Embodiment 3: the preparation of table tennis racket

[0037] The first step is to shape the preformed thermal self-expanding high-energy adhesive HR-313, put it into the core material mold of the product and tighten the mold. The temperature is 90°C, heated for 30 minutes, and slightly expanded. The volume ratio before and after the expansion is 1.5 , fill the mold cavity, cool, and obtain the core material of the table tennis racket;

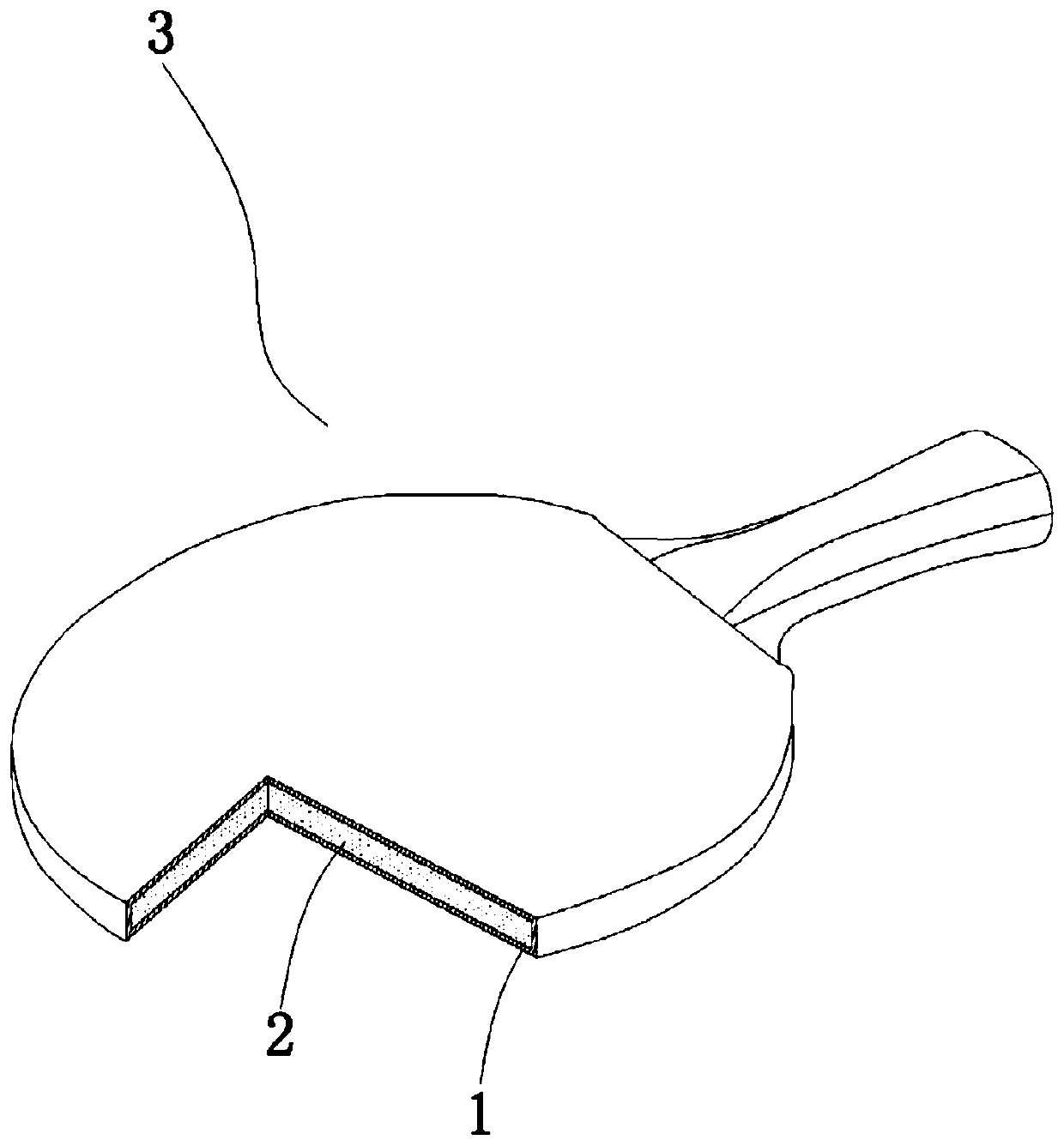

[0038] The second step is to wrap three layers of glass fiber prepreg cloth on the outside of the core material of the table tennis racket; put it into the molding mold and close the mold, and heat it to 120°C for 60 minutes; at this time, the thermal self-expanding high-energy adhesive will produce Expansion force from inside to outside, at the same time, the glass fiber prepreg is solidified and molded, and the table tennis racket is obtained after cooling and demoulding. structure see figure 1 and figure 2 . Among them, 1 is a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com