Double-faced indexable four-cutting-edge milling insert

A milling insert and indexing technology, used in milling cutters, milling machine equipment, manufacturing tools, etc., can solve the problems of poor economy and less use, and achieve the effects of good economy, simple mechanism, and simple adjustment mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

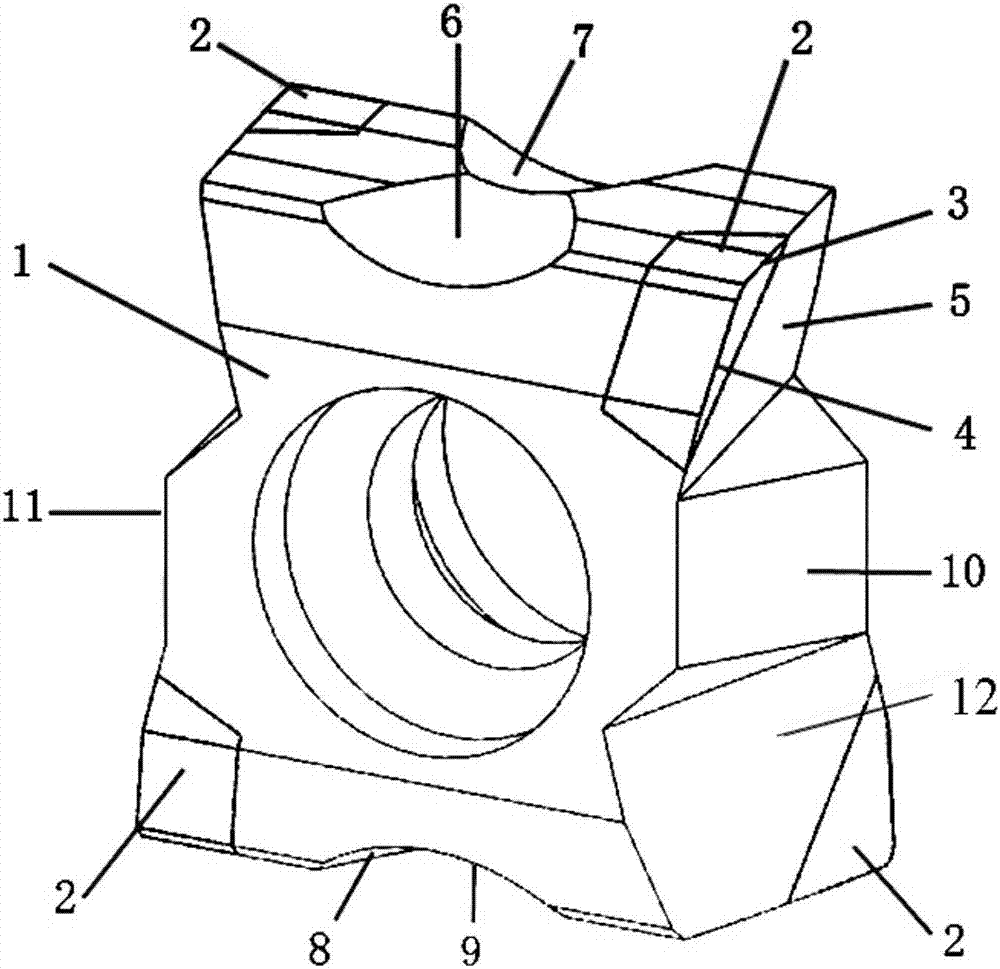

[0026] The present invention will be further described in detail below in conjunction with the drawings. Following figure 1 The first tapered surface 6 in the upper side defines the direction, which is only for describing the present invention more clearly, rather than limiting the present invention.

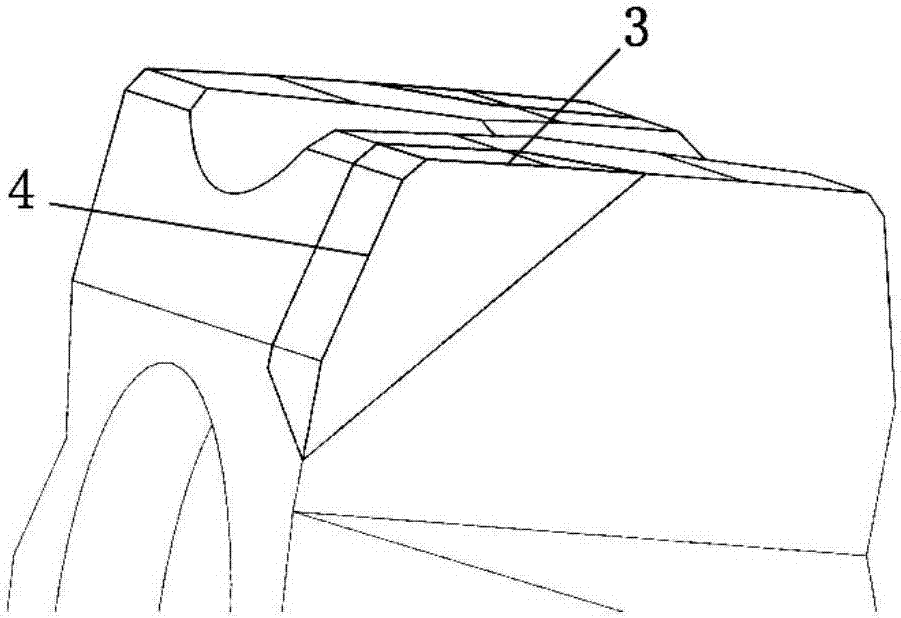

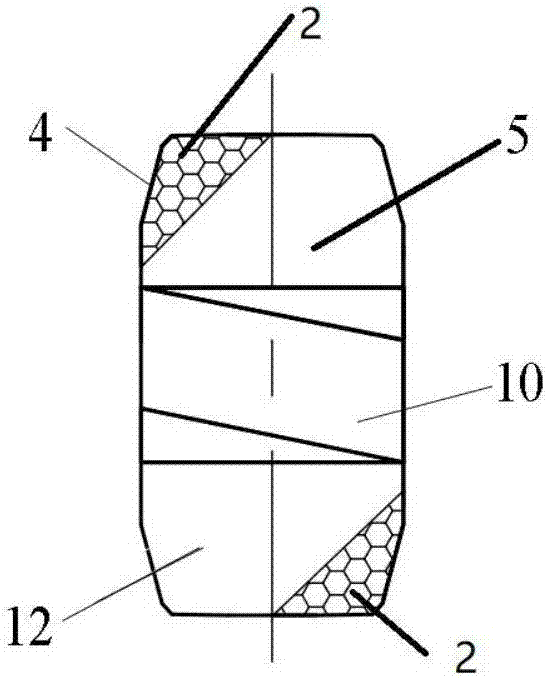

[0027] See Figure 1 to Figure 5 The present invention includes a base 1 and four welded sheets 2 staggered on the four vertices of the base 1. Each welded sheet 2 is provided with a cutting edge; each cutting edge includes a main cutting edge 3 and a secondary The cutting edge 4, the main cutting edge 3 and the secondary cutting edge 4 have an included angle of 100-110°, preferably 106°, so that the main cutting edge 3 involved in cutting is located at the highest point, while the secondary cutting edge 4 is not located in the entire insert The highest point can effectively protect the cutting edge, especially when it is installed on the cutter head, which can avoid protecting th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Taper | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com