Demolding assembly and method for beam

A demoulding and assembly technology, applied in the direction of unloading devices, manufacturing tools, etc., can solve the problems of high damage rate and low demoulding efficiency of beams, and achieve the effect of stable contact and simple and easy-to-operate adjustment mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

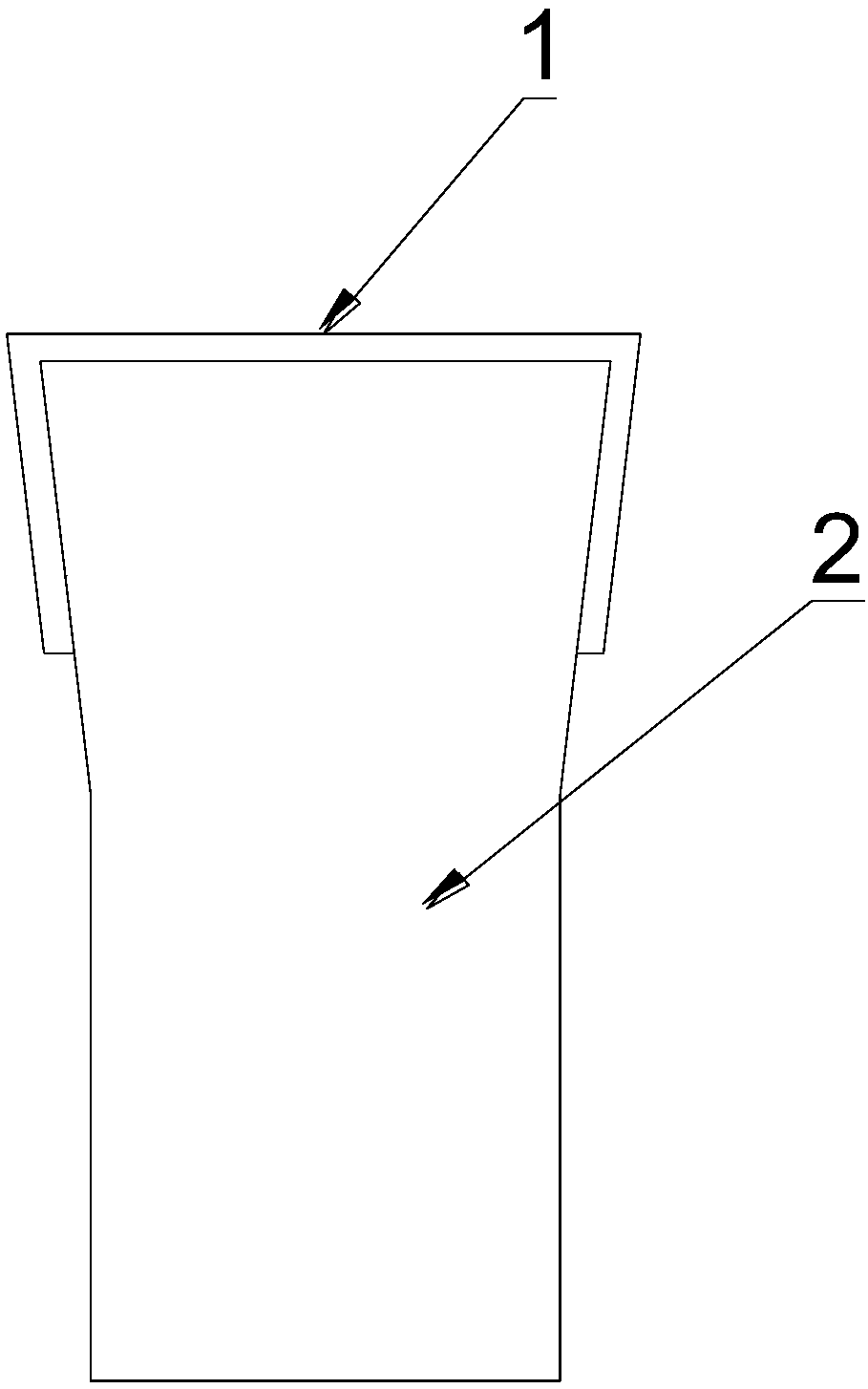

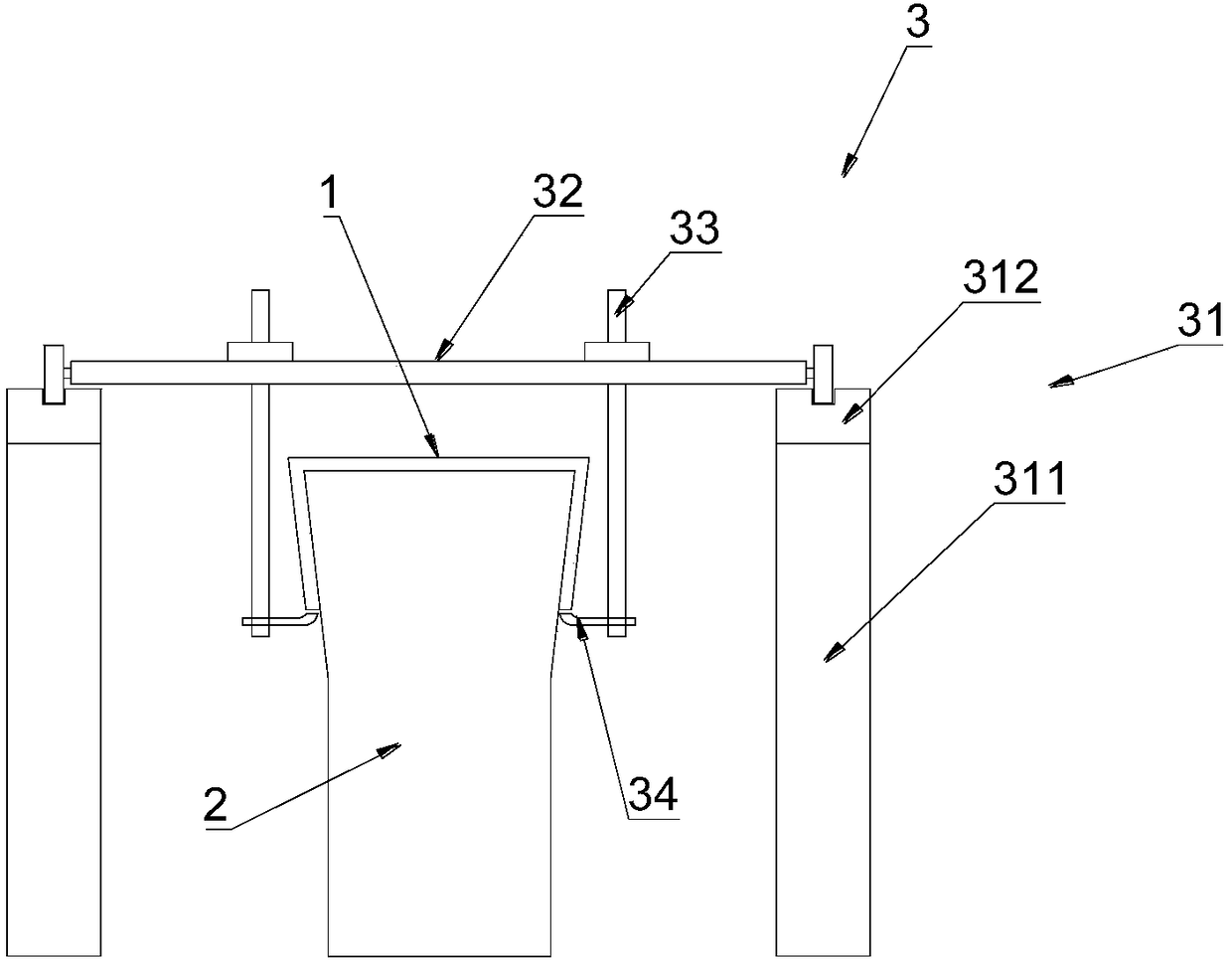

[0032] Such as figure 2 , image 3 As shown, a demoulding assembly for beams includes a lifting mechanism 3 for beams 1 and a separating and pushing mechanism 4 for beams 1 . The beam 1 is buckled on the mold 2 .

[0033] The lifting mechanism 3 includes a bracket 31 and a moving beam 32 fixed on the first bracket 31; the bracket 31 includes rails 312 fixed on both sides of the beam 1 through a vertical rod 311, and the moving beam 32 is perpendicular to the axis of the beam 1 Crossing the beam 1 ; the two ends of the moving beam 32 are fixed with rollers 321 that cooperate with the track, so that the moving beam 32 can move forward and backward along the axis of the beam 1 . A lifting part is fixed on the moving beam 32, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com