Copper pipe shrinking equipment

A technology of copper tube and necking, which is applied in the direction of shearing machine equipment, metal processing equipment, pipe shearing device, etc., can solve the problems of low degree of automation and unsatisfactory necking quality, achieve high degree of automation and reduce production and processing procedures , Ease of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments:

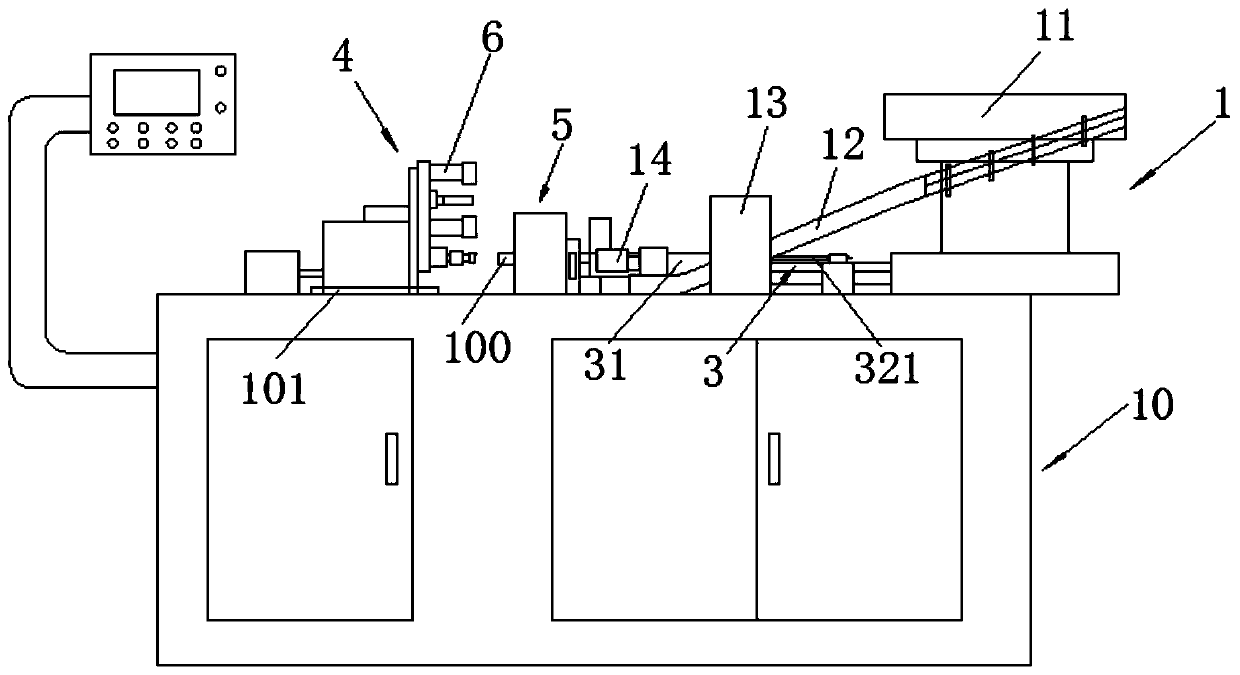

[0032] See figure 1 , A copper pipe necking device, comprising a machine 10 and a feeding mechanism 1, a pushing mechanism 3 and a necking mechanism 4 provided on the machine 10;

[0033] The feeding mechanism 1 sorts the chaotic copper pipes 100 put into it and sends them to the pushing mechanism 3 one by one. The first implementation of the feeding mechanism 1 is as follows:

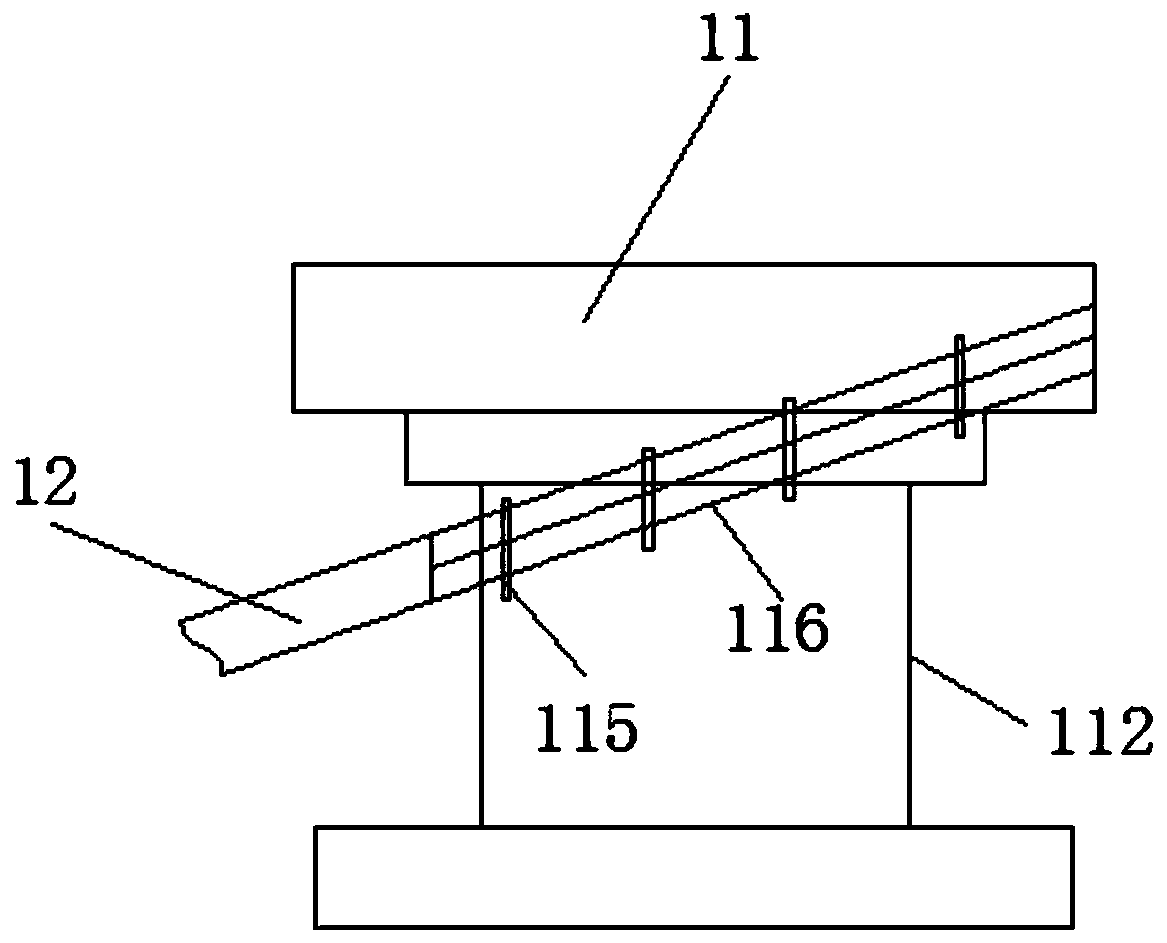

[0034] The feeding mechanism 1 includes a disc hopper 11, a linear track 12, a linear feeder 13 and a clamping mechanism 14;

[0035] See Figure 1 to Figure 3 , The disc hopper 11 is provided with a spiral upward spiral track 111; below the disc hopper 11 is provided a chassis housing 112, the chassis housing 112 is provided with a pulse electromagnet 113 and a tilted spring plate 114, one end of the spring plate 114 It is fixedly connected to the disc hopper 11, and the other en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com