Rotary type spinning reducing device

A rotary and rotating body technology, applied in the field of metal pipe processing equipment, can solve the problems of metal pipe hardness requirements and inapplicability, and achieve the effect of improving the quality of necking finished products, good necking quality, and improving processing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

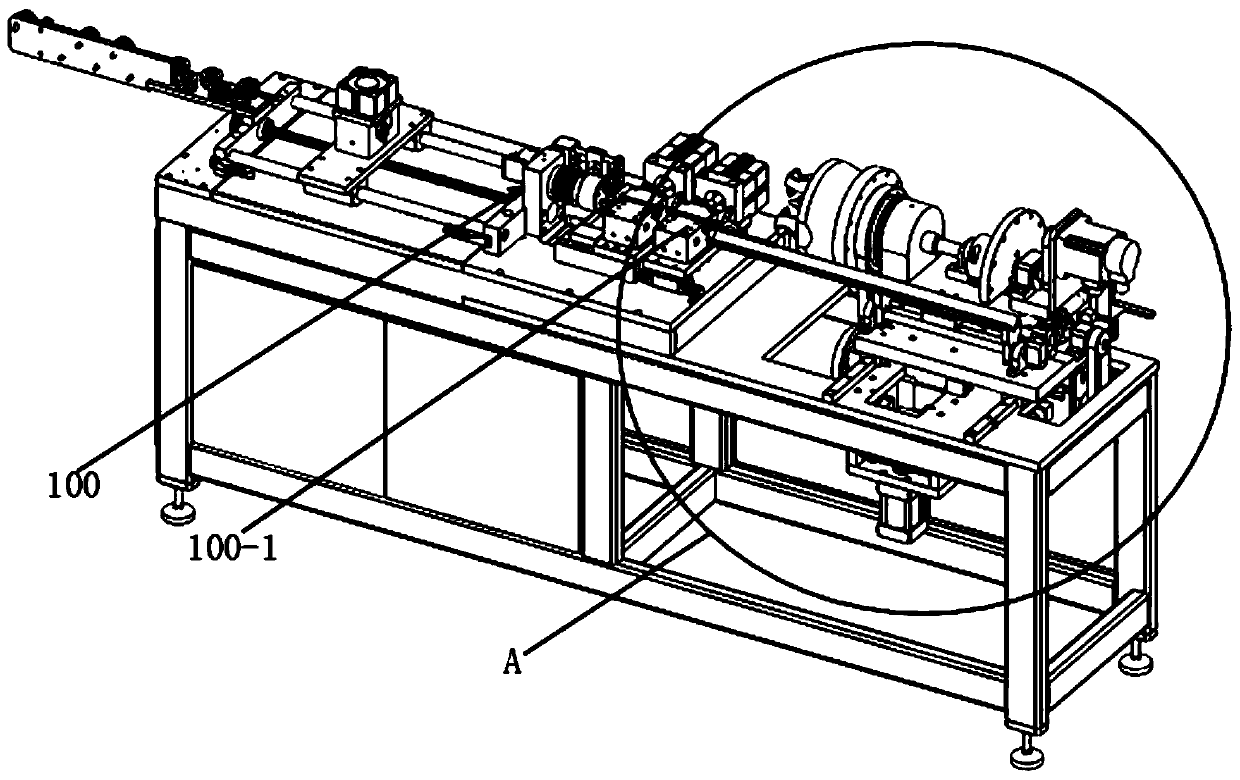

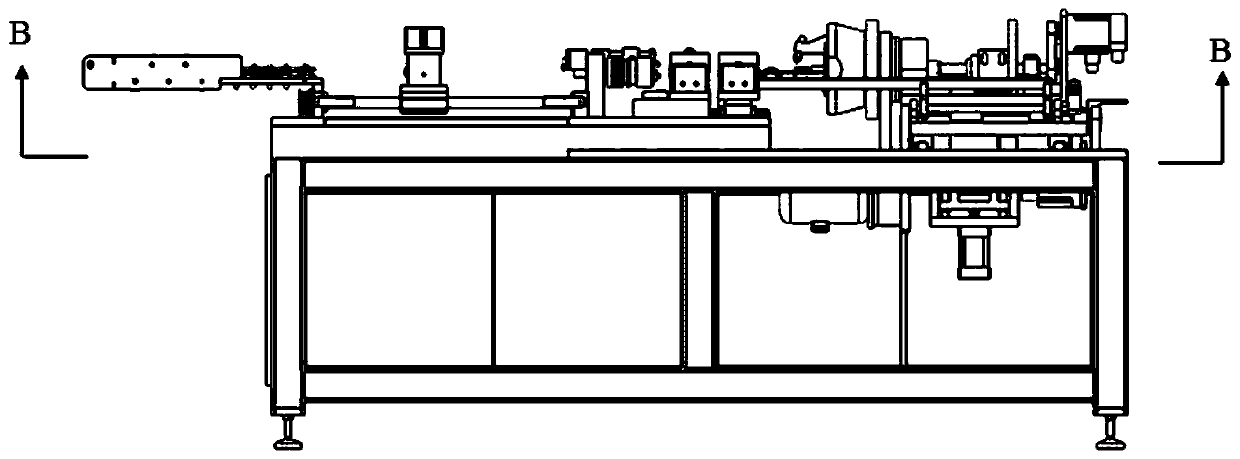

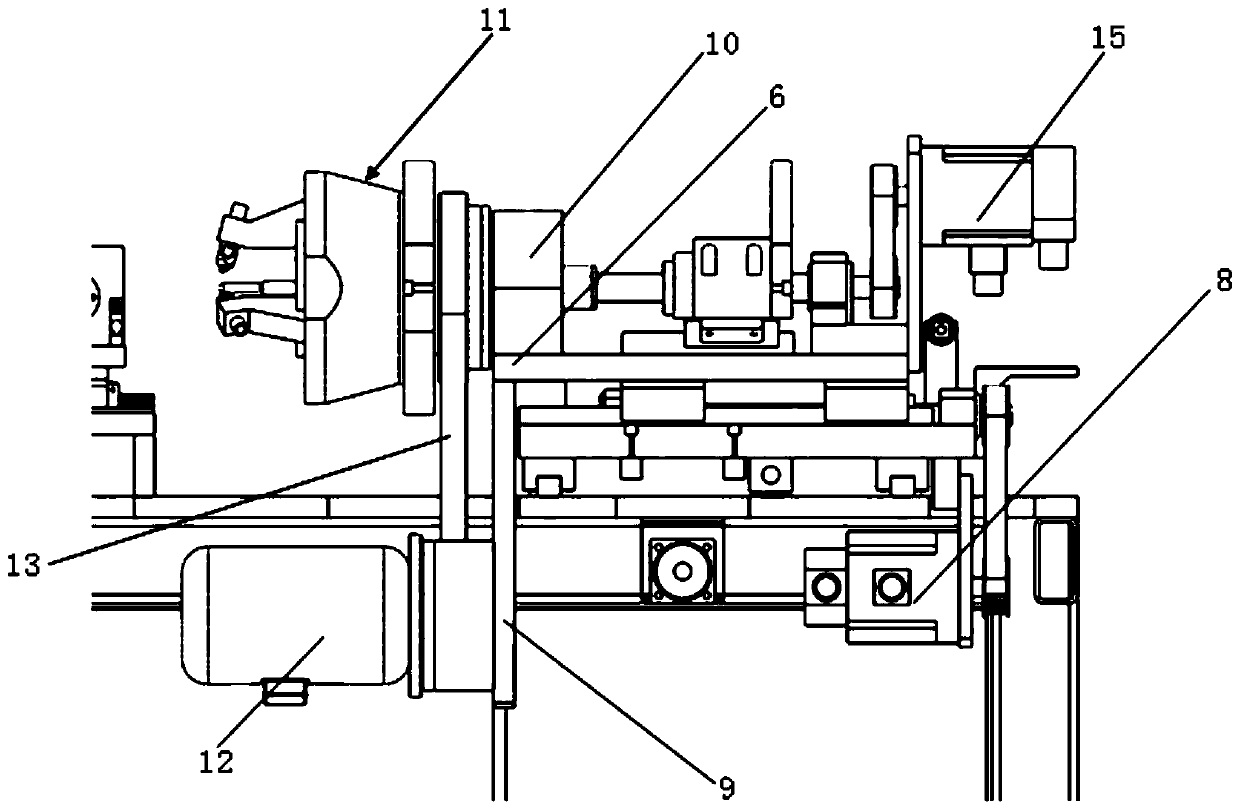

[0018] See attached Figure 1-8 As shown, the rotary compression port device includes a blanking machine 100 and a rotary rotary compression port device located on the side of the blanking machine 100. The rotary rotary compression port device includes a frame 1 and is located on the The first slide rail 2 on the frame 1, the offset plate 3 is installed on the first slide rail 2, the first cylinder 4 is arranged on the frame 1 and connected to the offset plate 3, What is installed on the described offset plate 3 is the second slide rail 5, and the base plate 6 is installed on the described second slide rail 5, and what links to each other with the described base plate 6 is the first leading screw 7, drives described first wire What the bar 7 rotates is the first servo motor 8, a mounting plate 9 is provided on the side of the base plate 6, a bearing 10 is installed at the junction of the base plate 6 and the mounting plate 9, and the rotary compression head 11 is installed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com