Can cleaning and air-drying device

An air-drying device and canned technology, which is applied in the directions of drying gas arrangement, drying, drying machine, etc., can solve the problems of only washing the side wall and upper surface of the tank body, unable to clean the bottom of the tank body, and incomplete cleaning, etc. Achieve the effect of reducing plant area, saving energy and avoiding wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

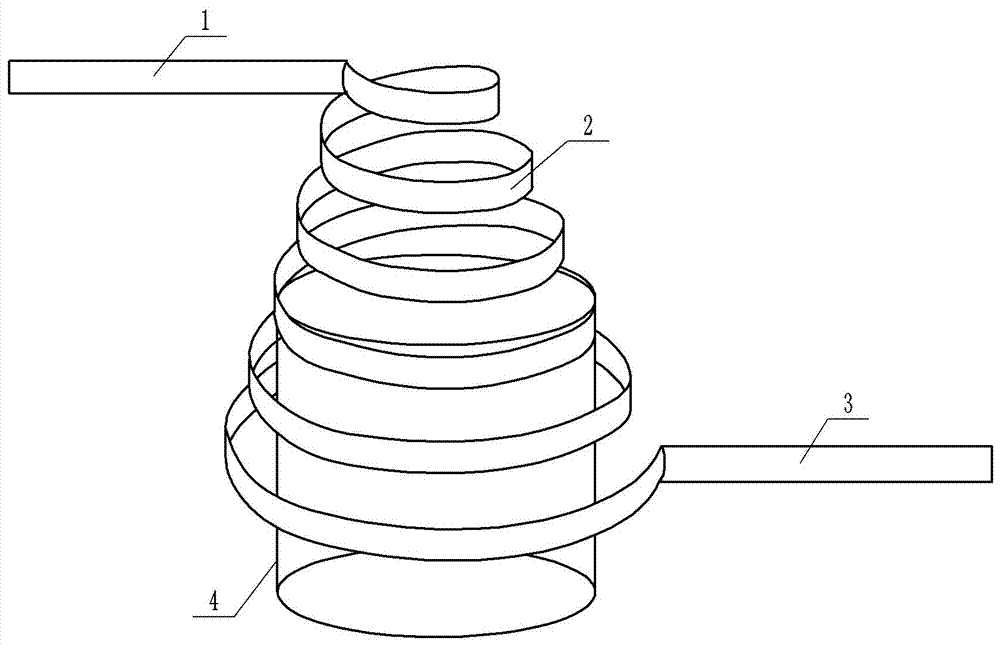

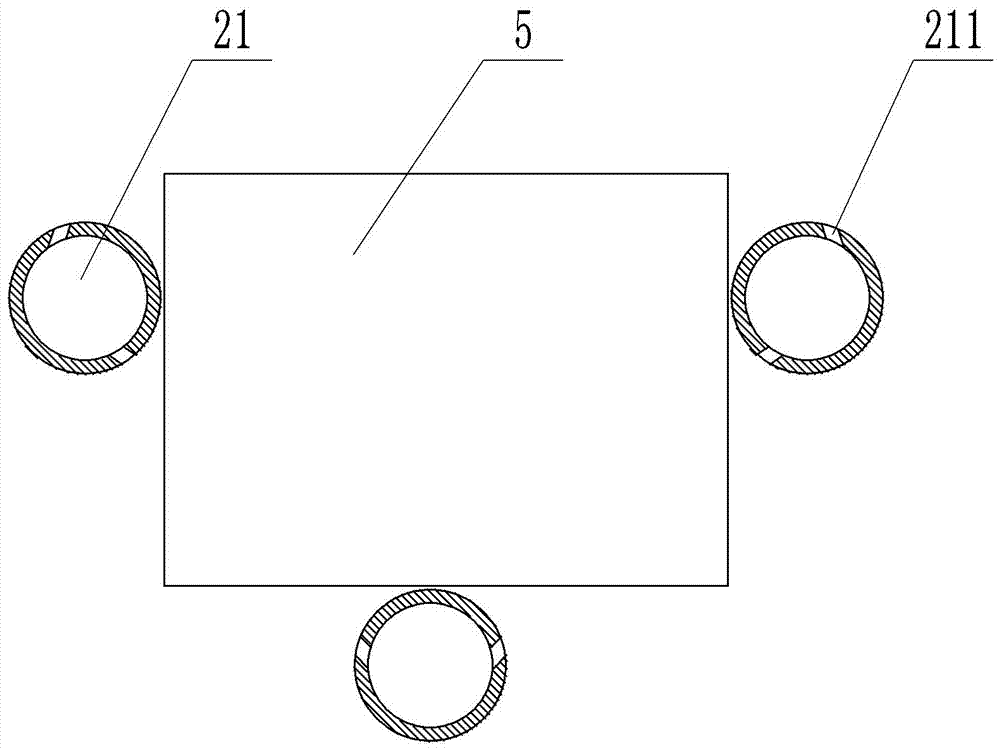

[0022] Such as figure 1 As shown, the can washing and air-drying device includes an upper transmission device 1, a spiral track 2 and a lower transmission device 3 from top to bottom, the upper transmission device 1 is located on the side of the entrance above the spiral track 2, and the lower transmission device 3 is located on the spiral track 2 side of the lower exit. Such as figure 2 As shown, the spiral track 2 includes 3 pipes 21, the 3 pipes 21 are respectively located on the left and right sides and the bottom of the can 5 to be transported, and the 3 pipes 21 form a whole by welding, and the 3 pipes 21 are used for supporting and Canned food 5 is conveyed; the spiral track 2 is designed as a spatial spiral as a whole, and the diameter of the spiral increases gradually from top to bottom. The spiral track 2 includes an upper part and a lower part, and a barrel-shaped support 4 is arranged at the junction of the upper part and the lower part. A drain valve is install...

Embodiment 2

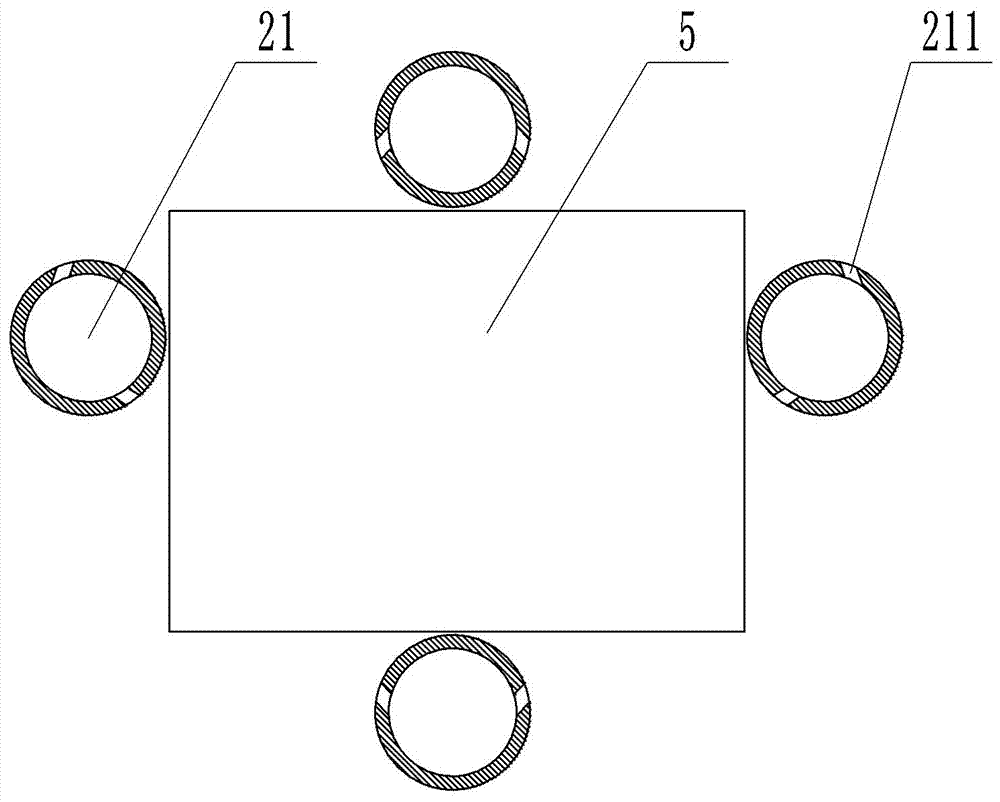

[0025] The difference between embodiment 2 and embodiment 1 is that the spiral track 2 of embodiment 2 includes four pipes 21, which are respectively located on the four sides of the cans 5 to be transported, up, down, left, and right, as image 3 shown. There are four pipelines 21, and the canned food 5 will not be thrown out of the spiral track 2 during the transmission process, which ensures the reliability and safety of the transportation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com