Electrostatic powder spraying technique for part of child dinning chair

A technology for electrostatic powder and dining chairs, applied in coatings, devices for coating liquids on surfaces, and surface pretreatment, etc., can solve the problems of low aesthetics of the coating, easy damage to the coating, rough hand feeling, etc., to increase the aesthetic feeling. , Improve safety performance, bright and uniform attractive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

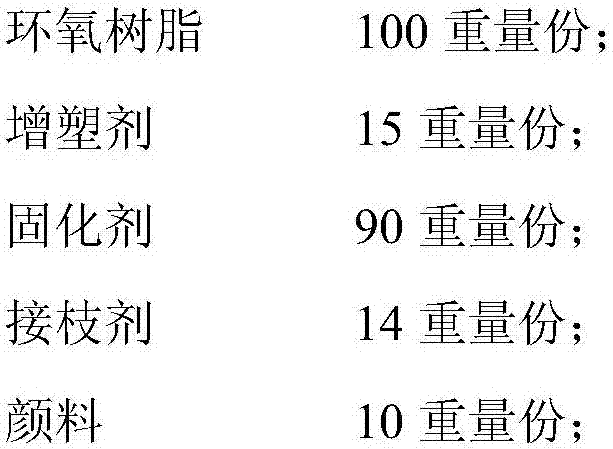

Embodiment 1

[0050] An electrostatic powder spraying process for children's dining chair accessories, step S1 specifically includes the following steps:

[0051] S1.1 Substrate surface pretreatment:

[0052] S1.1.1 Perform two liquid blasting treatments on the surface of the substrate. The first liquid sand blasting uses a sand particle size of 0.1 mm, the second liquid sand blasting uses a sand particle size of 0.5 mm, and the first liquid sand blasting uses a sand particle size of 0.5 mm. The duration of the liquid blasting treatment is 30s, the duration of the second liquid blasting treatment is 10s, and the angle between the blasting direction of the first liquid blasting treatment and the blasting direction of the second liquid blasting treatment is greater than 0° And less than 180°;

[0053] S1.1.2 Degreasing the surface of the substrate after the treatment in step S1.1.1;

[0054] S1.1.3 Dry the base material after degreasing treatment in step S1.1.2 with hot air at 40°C for 3 mi...

Embodiment 2

[0073] An electrostatic powder spraying process for children's dining chair accessories, step S1 specifically includes the following steps:

[0074] S1.1 Substrate surface pretreatment:

[0075] S1.1.1 Perform two liquid blasting treatments on the surface of the substrate. The first liquid sand blasting uses a sand particle size of 0.2 mm, the second liquid sand blasting uses a sand particle size of 1 mm, and the first liquid sand blasting uses a sand particle size of 1 mm. The duration of the sandblasting treatment is 30s, the duration of the second liquid sandblasting treatment is 10s, the angle between the sandblasting direction of the first liquid sandblasting treatment and the sandblasting direction of the second liquid sandblasting treatment is greater than 0° and Less than 180°;

[0076] S1.1.2 Degreasing the surface of the substrate after the treatment in step S1.1.1;

[0077] S1.1.3 Dry the base material after degreasing treatment in step S1.1.2 with hot air at 50°C...

Embodiment 3

[0096] An electrostatic powder spraying process for children's dining chair accessories, step S1 specifically includes the following steps:

[0097] S1.1 Substrate surface pretreatment:

[0098] S1.1.1 Perform two liquid blasting treatments on the surface of the substrate. The first liquid sand blasting uses a sand particle size of 0.1 mm, the second liquid sand blasting uses a sand particle size of 0.8 mm, and the first liquid sand blasting uses a sand particle size of 0.8 mm. The duration of the liquid blasting treatment is 30s, the duration of the second liquid blasting treatment is 10s, and the angle between the blasting direction of the first liquid blasting treatment and the blasting direction of the second liquid blasting treatment is greater than 0° And less than 180°;

[0099] S1.1.2 Degreasing the surface of the substrate after the treatment in step S1.1.1;

[0100] S1.1.3 Dry the base material after degreasing treatment in step S1.1.2 with hot air at 45°C for 4 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com