Processing technology of black tea

A processing technology, black tea technology, applied in the field of black tea processing technology, can solve the problems of black tea fragrance not lasting, unfavorable market sales, affecting tea quality, etc., to increase the formation of water-soluble pectin and monosaccharide, and the ratio of phenolic ammonia Reduced, lingering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

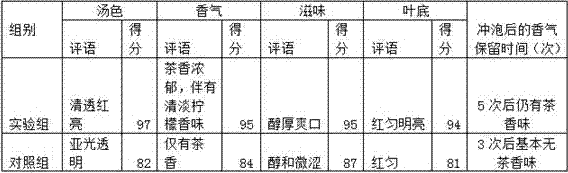

Examples

Embodiment 1

[0019] Embodiment 1: a kind of processing technology of black tea, comprises the following steps:

[0020] Step 1. Withering: After 5:00 p.m., spread the picked fresh tea leaves on a withering mat and place them at room temperature for withering. The thickness of the spread leaves is 0.8-1.3 cm. After spreading for 0.5-1 hour, put the tea leaves into fresh-keeping After sealing the fresh-keeping bag, place it in a freezer at -20°C for 2 to 2.5 hours to obtain withered leaves;

[0021] Step 2, kneading: put the withered leaves in the kneading machine and knead; prepare fresh lemons, use fresh lemons to prepare lemon juice, and after the tea leaves are kneaded for 5 to 6 minutes, spray the lemon juice in the tea leaves. The weight of the lemon juice sprayed is 20% of the weight of the tea leaves; then continue to knead for 5-6 minutes;

[0022] Step 3. Fermentation: Put the rolled tea leaves into a fermenter, and ferment for 2-3 hours at a temperature of 28°C and a relative hum...

Embodiment 2

[0024] Embodiment 2: a kind of processing technology of black tea, comprises the following steps:

[0025] Step 1. Withering: After 5:00 p.m., spread the picked fresh tea leaves on a withering mat and place them at room temperature for withering. The thickness of the spread leaves is 0.8-1.3 cm. After spreading for 0.5-1 hour, put the tea leaves into fresh-keeping After sealing the fresh-keeping bag, place it in a freezer at -18°C for 2 to 2.5 hours to obtain withered leaves;

[0026] Step 2, kneading: put the withered leaves in the kneading machine and knead; prepare fresh lemons, use fresh lemons to prepare lemon juice, and after the tea leaves are kneaded for 5 to 6 minutes, spray the lemon juice in the tea leaves. The weight of the lemon juice sprayed is 18% of the weight of the tea leaves; then continue rolling for 5-6 minutes;

[0027] Step 3. Fermentation: Put the rolled tea leaves into a fermenter, and ferment for 2-3 hours in an environment with a temperature of 22°C...

Embodiment 3

[0029] Embodiment 3: a kind of processing technology of black tea, comprises the following steps:

[0030] Step 1. Withering: After 5:00 p.m., spread the picked fresh tea leaves on a withering mat and place them at room temperature for withering. The thickness of the spread leaves is 0.8-1.3 cm. After spreading for 0.5-1 hour, put the tea leaves into fresh-keeping After sealing the fresh-keeping bag, place it in a freezer at -17°C for 2 to 2.5 hours to obtain withered leaves;

[0031] Step 2, kneading: put the withered leaves in the kneading machine and knead; prepare fresh lemons, use fresh lemons to prepare lemon juice, and after the tea leaves are kneaded for 5 to 6 minutes, spray the lemon juice in the tea leaves. The weight of the lemon juice sprayed is 24% of the weight of the tea leaves; then continue to knead for 5-6 minutes and then take it out, put the kneaded tea leaves in a container equipped with a blower and blow them for 5-8 minutes.

[0032] Step 3. Fermentati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com