Electrical connector and manufacturing method thereof

A technology of electrical connectors and abutting parts, which is applied in the field of electrical connectors and its manufacturing, can solve problems such as spot welding failure, affecting use, and deformation at bending places, and achieves good strength and rigidity, is not easy to deform, and enhances the holding effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

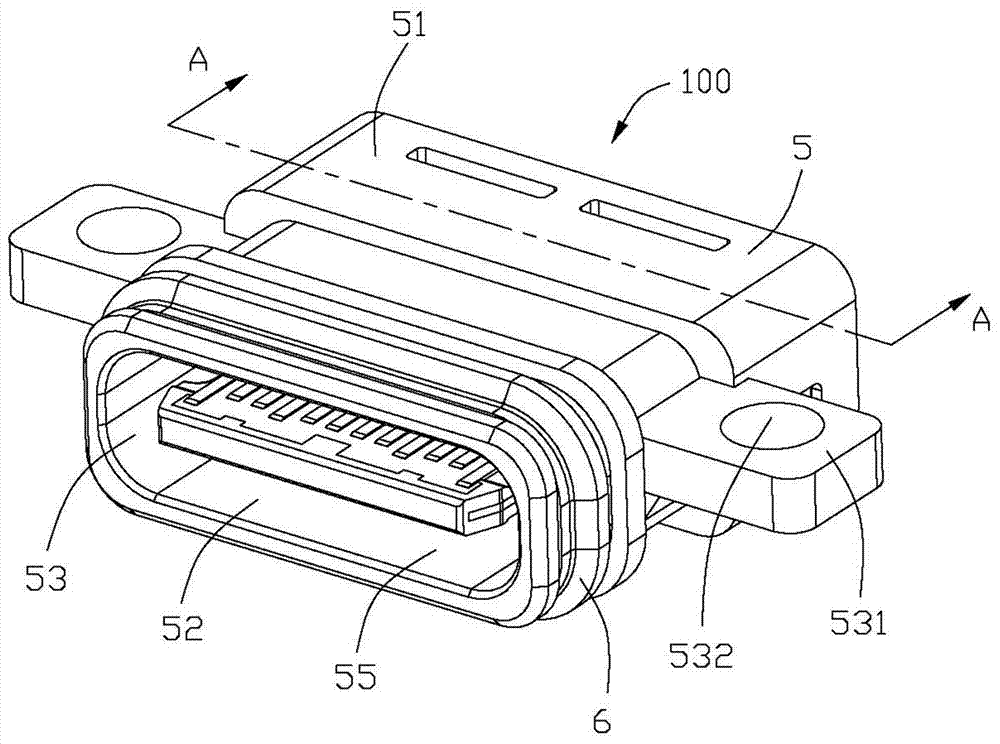

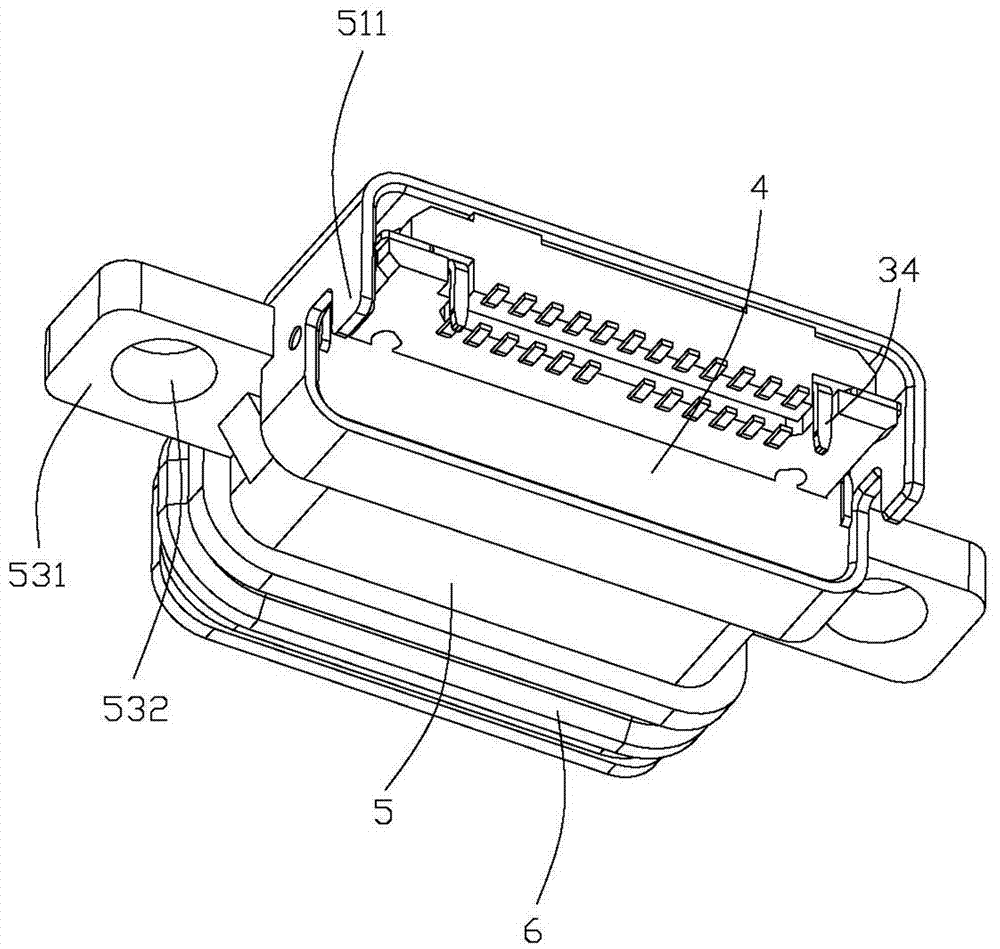

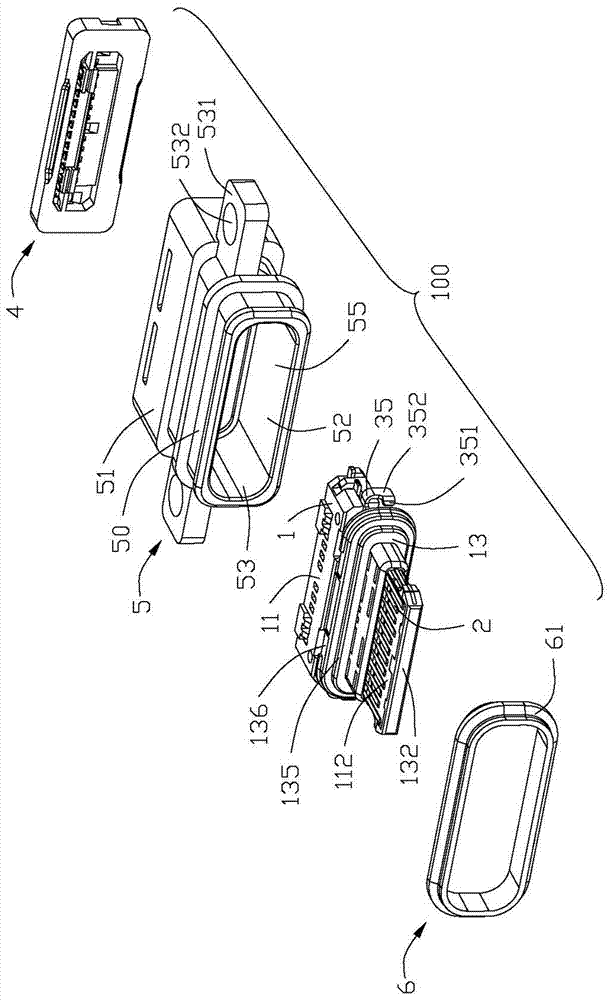

[0027] Below, will combine Figure 1 to Figure 8 A specific implementation manner of the electrical connector 100 of the present invention is introduced. The port where the electrical connector 100 is plugged with the mating connector is defined as the plug-in end. Define a docking direction, a transverse direction, and a vertical direction perpendicular to both the docking direction and the transverse direction, and the plane where the docking direction and the transverse direction are located constitutes a horizontal plane.

[0028] Please refer to Figure 1 to Figure 7 As shown, the electrical connector 100 of the present invention includes an insulating body 1, a plurality of terminals 2 held in the insulating body 1, a metal shielding sheet 3 held in the insulating body 1, a rubber plate 4 formed at the rear end of the insulating body 1, and a sleeve The shielding case 5 outside the insulating body 1 and the waterproof gasket 6 sleeved outside the port of the shielding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com