Transport equipment steel ladle path compilation method of considering production equipment scheduling plan constraints

A technology for scheduling planning and production equipment, applied in computing, manufacturing computing systems, instruments, etc., can solve the problems of continuous casting and pouring, affecting the smooth operation of steelmaking production, and idle equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

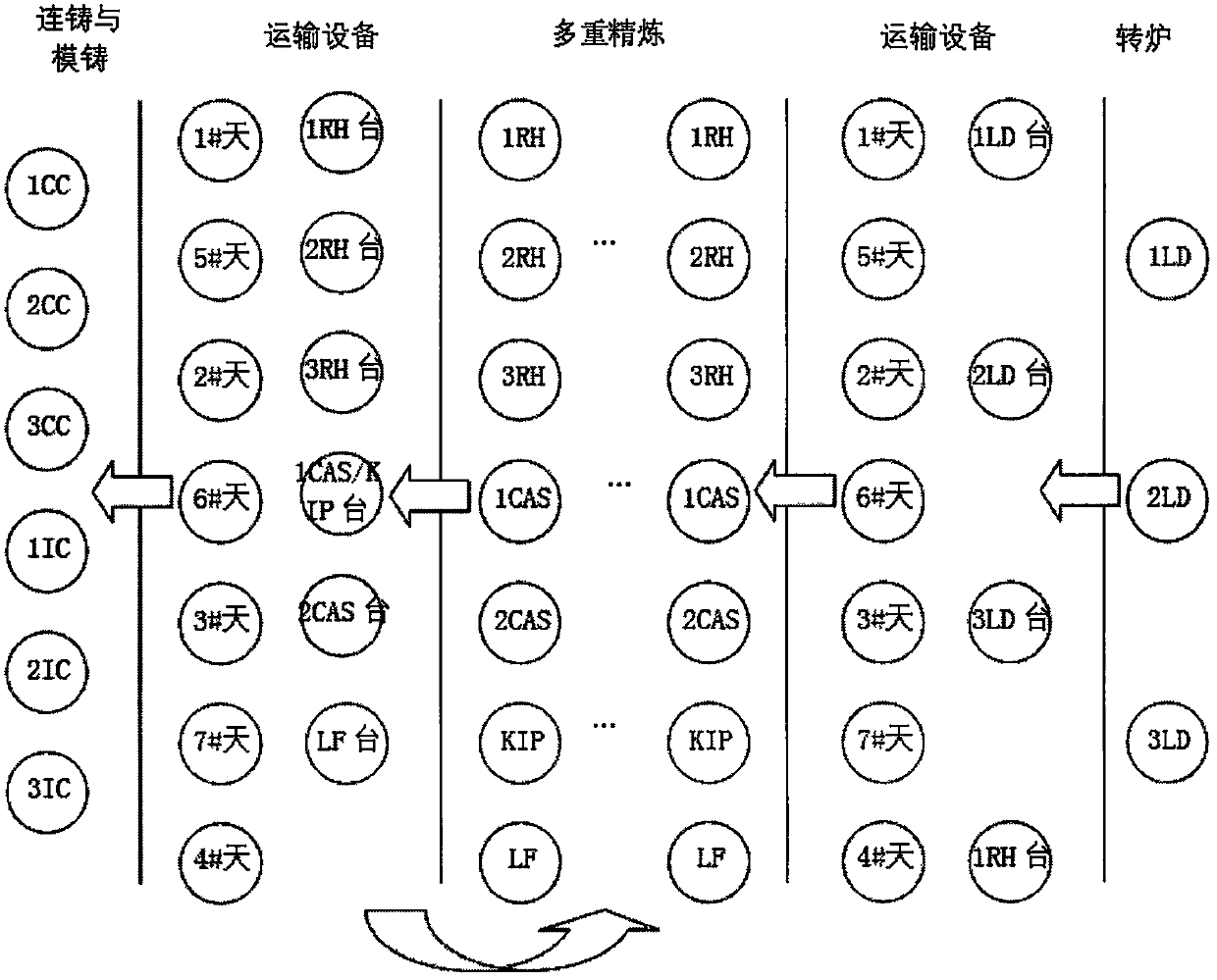

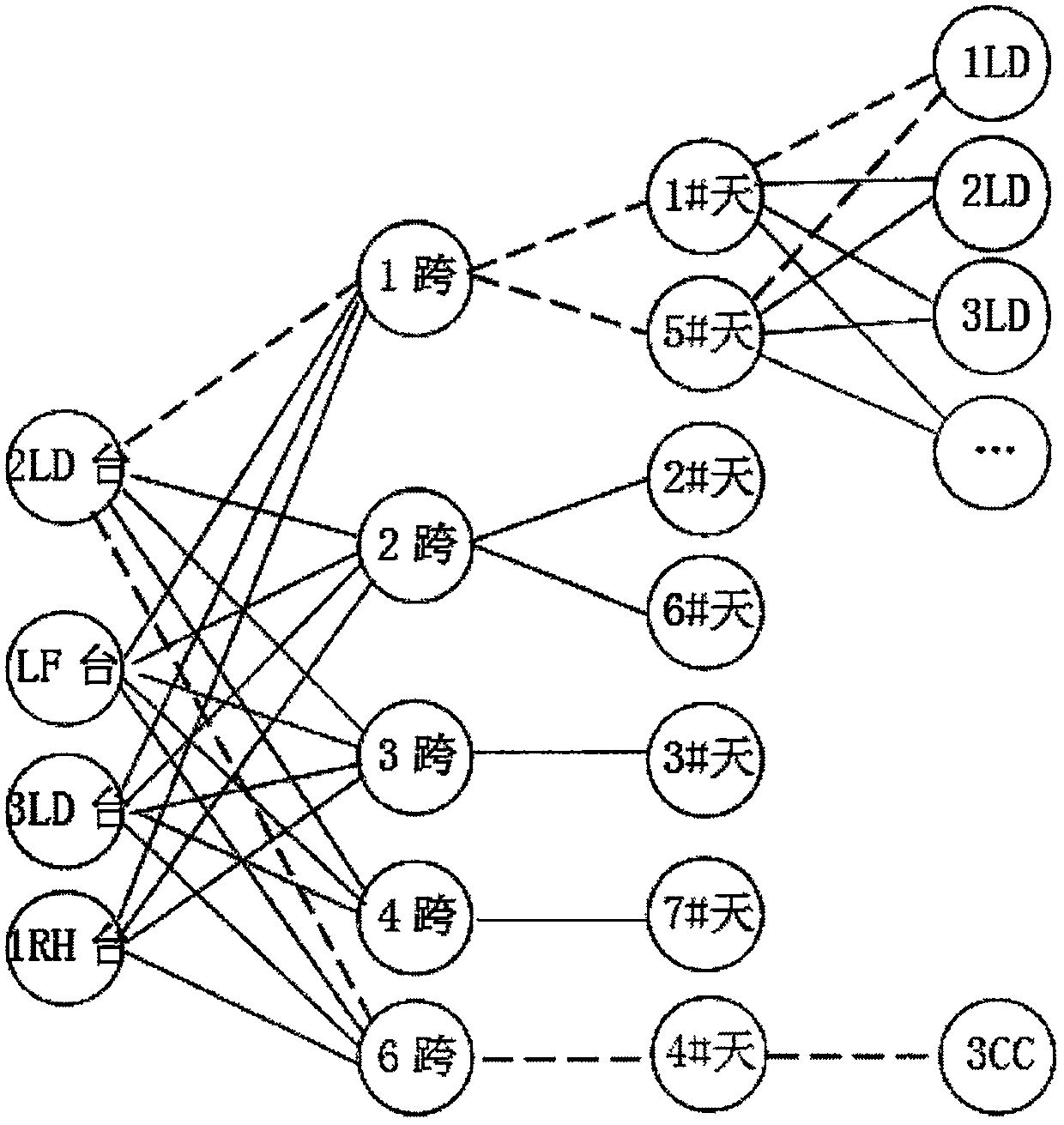

[0137] There are 7 cranes and 9 trolleys on site. The analysis of determining the ladle path strategy is as follows:

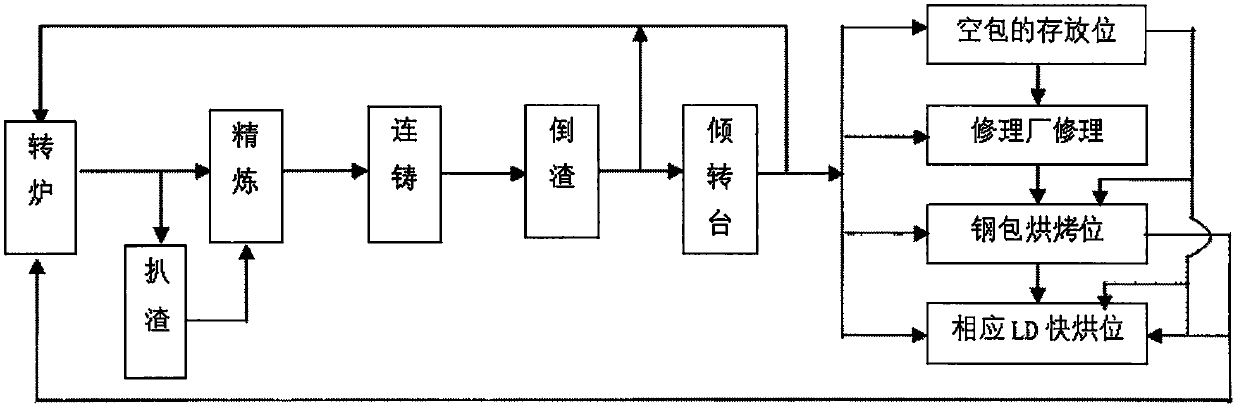

[0138] (1) The ladle plan at the time of full ladle has been programmed, and the ladle transportation that will occur will be obtained according to the route and time of the scheduled steel delivery plan (the work that causes the position of the ladle to move is considered as ladle transportation). Obtain the starting point S and the ending point T of ladle movement according to the predetermined steel tapping sequence plan, and search for the basic path set φ to judge whether it can be reached.

[0139] (2) According to the equipment status and agreement, delete unavailable path nodes to obtain the available path set φ′. If the starting point S and the ending point T can be directly reached, go to step (8), otherwise go to step (3).

[0140] (3) According to the steel tapping plan and ladle plan, decompose the available path into several ladle operation int...

Embodiment 2

[0220] The initial data is described as follows: the production equipment scheduling plan contains 3 pouring times, and each pouring time includes 4 heats, that is, J 1 =J 2 =J 3 =4. The heat processing sequence sets of the 3 pouring times are respectively Among them, furnace number L 11 , L 12 , L 21 , L 22 , L 23 , L 31 Ladle routing has been programmed.

[0221] Step1: Initialize the heat set Φ to be empty. Obtain all the heats L currently produced through the production equipment scheduling plan ij (i=1,2,3; j=1,2,...,N i ) into the set Φ, as shown in Table 1.

[0222] Table 1 Casting plan

[0223]

[0224] Step2: Initialize the transport interval set Ψ to be empty, for the heat L in the set Φ ij (i=1,2,3; j=1,2,...,N i ) According to the heat L ij Total number of operations from converter to continuous casting process Divide the transportation interval and put it into the set Ψ;

[0225] Step3: Remove the transportation interval set Ψ={ψ 1 , ψ 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com