Automatic oil absorbing and oil changing equipment

An automatic and equipment technology, applied in special dispensing devices, packaging, dispensing devices, etc., can solve the problems of oil leakage and adhesion, inaccurate oil filling volume, dust adhered to the outer wall of the oil filling port, etc., and achieve oil filling Intelligent, free from manual oiling operations, saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

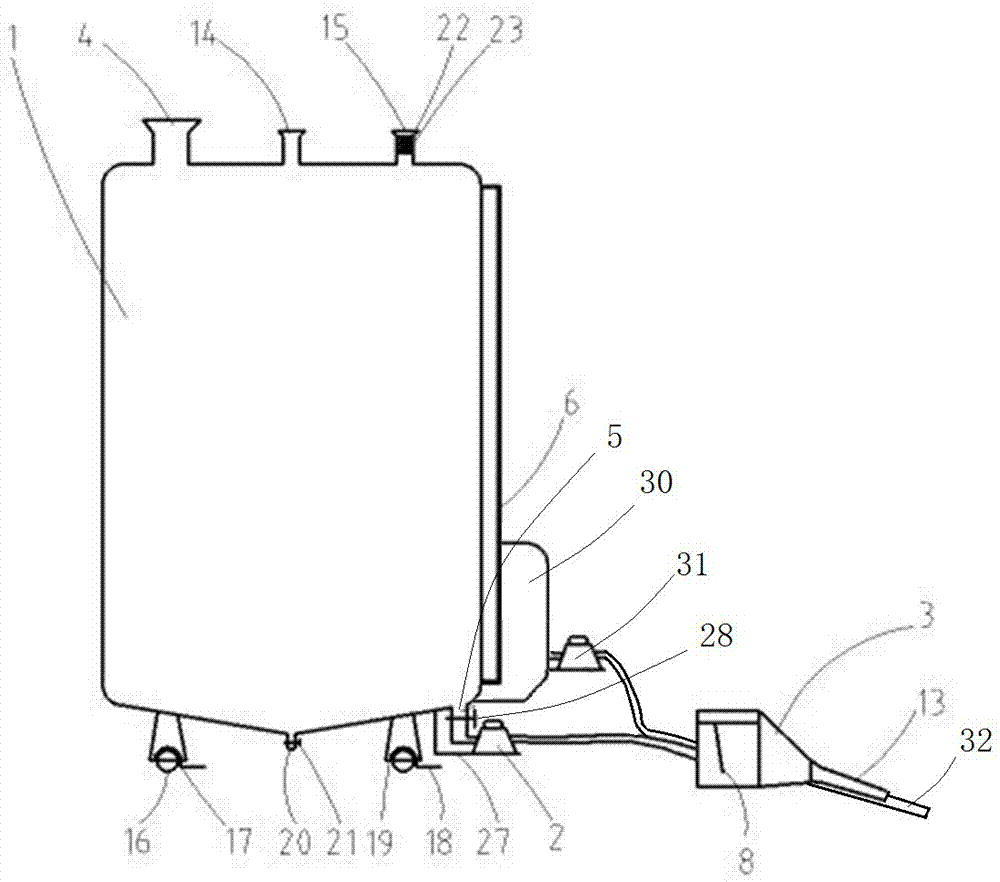

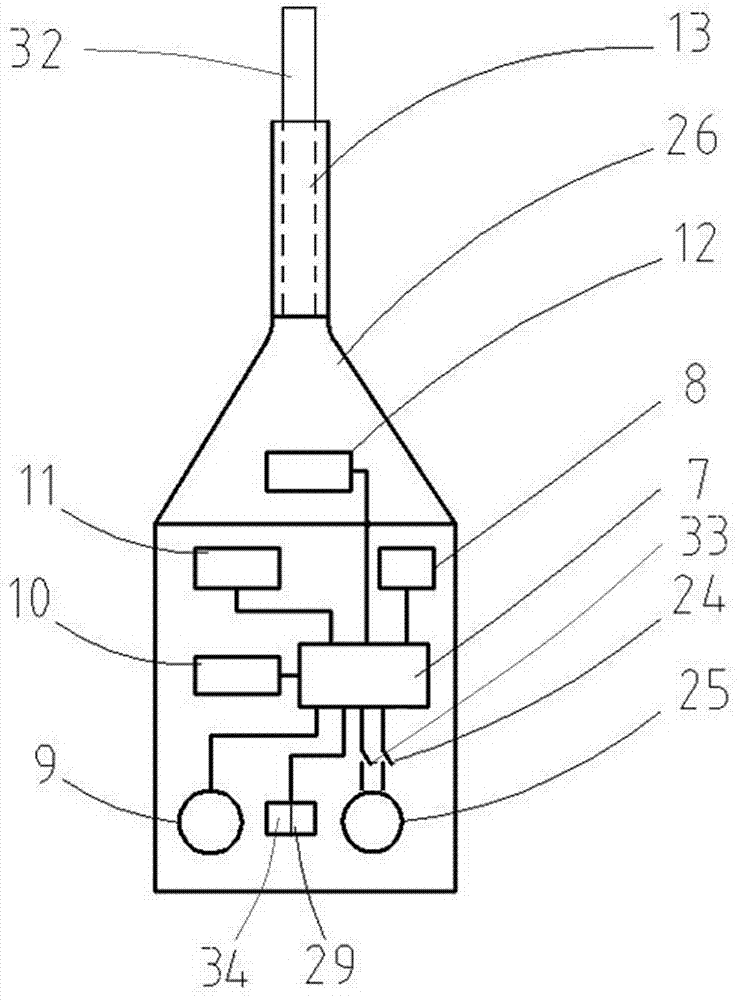

[0026] The invention discloses an automatic oil suction and oil change equipment, such as figure 1 and figure 2 As shown, it includes an oil storage tank 1, an oil injection pump 2, an oil gun 3, a waste oil tank 30 and an oil suction pump 31, wherein the oil storage tank 1 includes an oil inlet 4 and an oil outlet 5; one end of the oil injection pump 2 is connected to the outlet The oil port 5 is connected, and the other end is connected with the oil gun 3; one end of the oil suction pump 31 is connected with the waste oil tank 30, and the other end is connected with the oil gun 3; The oil injection nozzle 13 , and the oil suction nozzle 32 connected with the oil suction pump 31 , the oil suction nozzle 32 protrudes from the oil injection nozzle 13 .

[0027] The oil storage tank 1 also includes an oil gauge 6 , a cleaning port 14 , a breathing port 15 and a set of wheels 16 . The oil gauge 6 is connected to the oil storage tank 1 according to the principle of a connector....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com