Ultrafine powder packaging machine

A technology of ultra-fine powder and packaging machine, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items. It can solve the problems of flying powder, high production cost, and respiratory diseases, so as to prevent inhalation of dust, prevent dust from flying, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The content of the present invention will be described below in conjunction with specific embodiments.

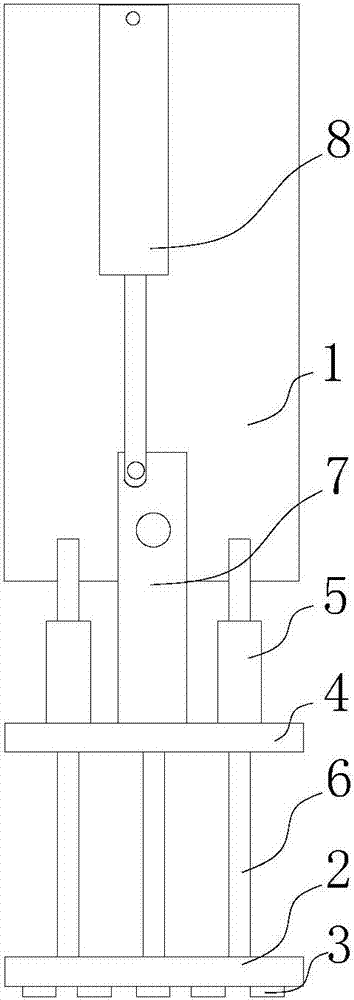

[0028] Such as Figure 1~4 as shown, figure 1 It is a structural schematic diagram of an ultrafine powder packaging machine proposed by the present invention; figure 2 It is a structural schematic diagram of the part where the film feeding system of a superfine powder packaging machine proposed by the present invention is located; image 3 yes figure 1 Partially enlarged schematic diagram of the part where the packaging system is located; Figure 4 It is a structural schematic diagram of the feeding mechanism of a superfine powder packaging machine proposed by the present invention.

[0029] refer to Figure 1~4 , the ultrafine powder packaging machine proposed by the present invention is used to pack ultrafine powder into plastic films, and includes a film feeding system, a packaging system and a holding system arranged on the frame 1 from the first to the las...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com