Heavy duty tires

A technology for heavy loads and tires, applied to heavy tires, special tires, tire parts, etc., can solve problems such as increased rolling resistance, and achieve the effects of preventing tire weight from increasing, improving wear resistance, and preventing rolling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

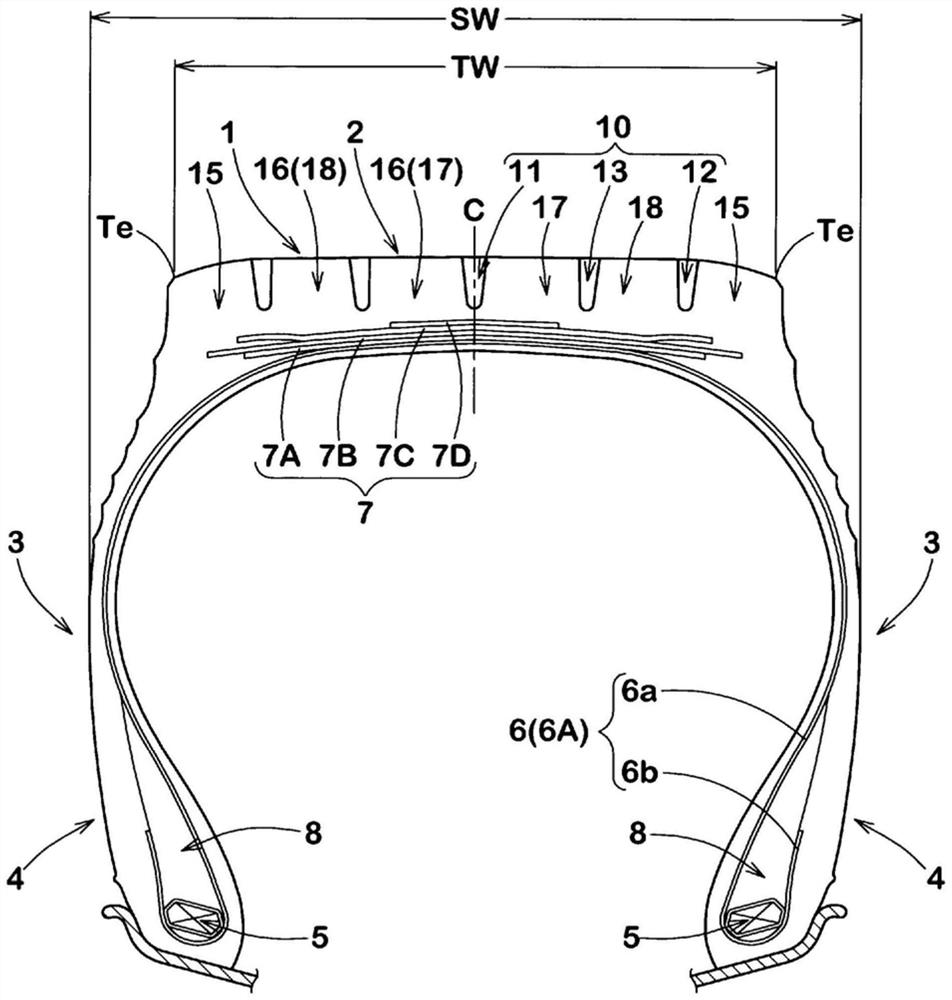

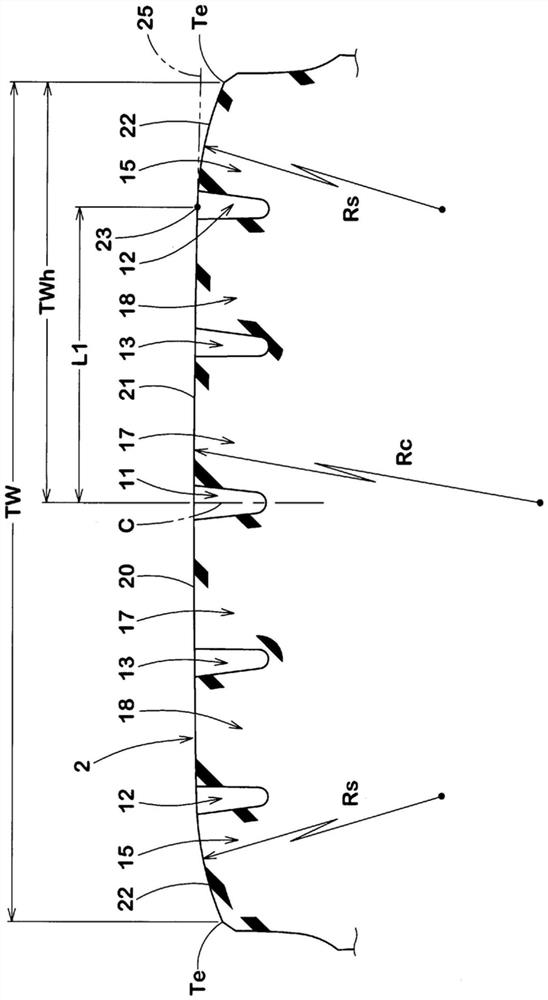

[0061] Based on the specifications in Table 1, manufactured with figure 1 The basic structure of the heavy-duty tire of size 12R22.5. As Comparative Example 1, a heavy duty tire having a ratio Rc / Rs of the radius of curvature Rc of the crown profile to the radius of curvature Rs of the shoulder profile Rs of less than 7.0 was manufactured. As Comparative Example 2, a heavy duty tire in which the distance L1 from the tire equator to the junction point was less than 0.70 times the tread half width TWh was manufactured. For each test tire, the wear amount and rolling resistance of the crown land portion were measured.

[0062] Common specifications of the respective test tires are as follows.

[0063] Tire size: 12R22.5

[0064] Rim size: 8.25×22.5

[0065] Tire internal pressure: 800kPa

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com