Antiseptic treatment technology for woodware

A technology for anti-corrosion treatment and wood products, applied in wood treatment, wood heat treatment, wood treatment details, etc., can solve the problems of reduced antibacterial effect, loss of active ingredients, hazards, etc., to improve antibacterial performance, increase service life, improve The effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

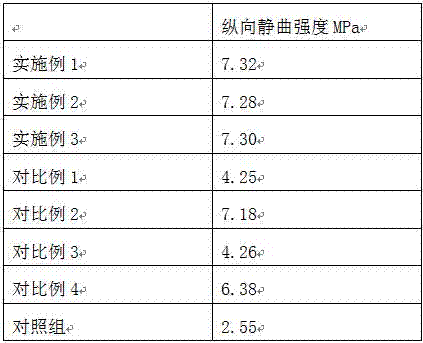

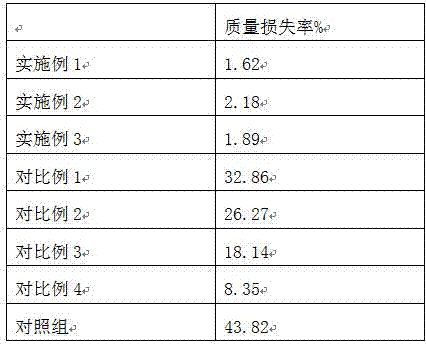

Examples

Embodiment 1

[0017] A wood product antiseptic treatment process, comprising the following steps:

[0018] (1) Surface treatment: Clean the surface of the wooden product and then polish it with sandpaper;

[0019] (2) Pre-impregnation treatment: The wood products treated in step (1) were vacuum-impregnated with chitosan solution for 2 hours, and vanillin was dissolved in ethanol to prepare a vanillin solution with a mass fraction of 5.5%. Pear leaves are crushed to 120 mesh, then added to distilled water with 5 times its mass, heated to 95°C, kept warm for 1 hour, and then filtered to obtain Pear leaf extract; after wood products are vacuum-impregnated in chitosan solution for 2 hours, the The vanillin solution is added to the chitosan solution, the mixing volume ratio of the chitosan solution and the vanillin solution is 2:1.2, ultrasonic treatment is performed for 10min, and then the quince leaf extract is added, and the amount of the quince leaf extract is chitosan 18% of the solution m...

Embodiment 2

[0027] A wood product antiseptic treatment process, comprising the following steps:

[0028] (1) Surface treatment: Clean the surface of the wooden product and then polish it with sandpaper;

[0029] (2) Pre-impregnation treatment: The wood products treated in step (1) were vacuum-impregnated with chitosan solution for 2 hours, and vanillin was dissolved in ethanol to prepare a vanillin solution with a mass fraction of 6.5%. Pear leaves are crushed to 120 mesh, then added to distilled water 5-8 times its mass, heated to 95°C, kept warm for 1 hour, and then filtered to obtain pear leaf extract; wood products are vacuum-impregnated in chitosan solution for 2 hours , the vanillin solution is added in the chitosan solution, the mixing volume ratio of the chitosan solution and the vanillin solution is 2: 1.5, ultrasonic treatment 15min, then add the quince leaf extract, the quince leaf extract addition amount is shell 20% of the mass of the polysaccharide solution, then continue t...

Embodiment 3

[0037] A wood product antiseptic treatment process, comprising the following steps:

[0038] (1) Surface treatment: Clean the surface of the wooden product and then polish it with sandpaper;

[0039] (2) Pre-impregnation treatment: The wood products treated in step (1) were vacuum-impregnated with chitosan solution for 2 hours, and vanillin was dissolved in ethanol to prepare a vanillin solution with a mass fraction of 5.8%. Pear leaves are crushed to 120 mesh, then added to distilled water with 6 times its mass, heated to 95°C, kept warm for 1 hour, and then filtered to obtain pine leaf extract; after wood products are vacuum-impregnated in chitosan solution for 2 hours, the Add the vanillin solution to the chitosan solution, the mixing volume ratio of the chitosan solution and the vanillin solution is 2:1.3, ultrasonic treatment for 12min, and then add the extract of the quince leaf, the amount of the extract of the quince leaf is chitosan 19% of the solution mass, then con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com