Supersonic swirling capture treatment system for flue gas

A processing system, supersonic technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of high investment cost, large greenhouse gas, large floor space, etc., and achieve low energy consumption and large processing capacity. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

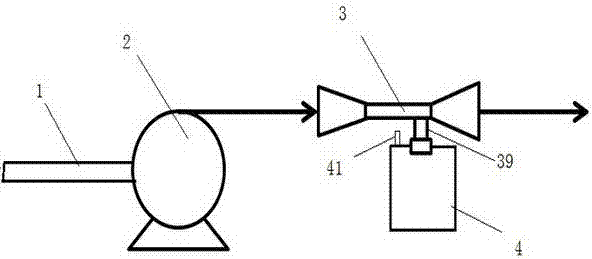

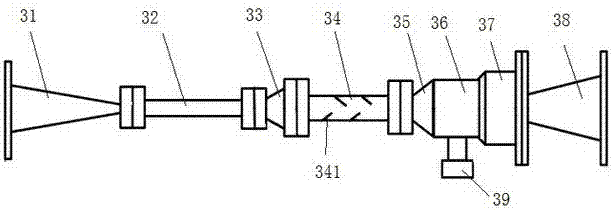

[0023] A supersonic cyclone capture and treatment system for flue gas, comprising a flue gas pipeline 1 , a compressor 2 , a cyclone separation pipe 3 and a collection device 4 . One end of the flue gas pipe 1 is connected to the flue gas pipe of the production system, the other end is connected to the inlet of the compressor 2, the outlet of the compressor 2 is connected to the inlet of the cyclone separation pipe 3, and the cyclone separation pipe 3 includes a jet expansion section, a swirl separation section and a diffusion deceleration section. The jet expansion section includes a first tapered pipe 31 and a first straight pipe 32. The large end of the first tapered pipe 31 is connected to the compressor 2 Outlet flange connection; the small end of the first tapered pipe 31 is flanged to one end of the first straight pipe 32, and the cyclone separation section includes a second tapered pipe 33, a second straight pipe 34 and a second straight pipe 34. The third composite pi...

Embodiment 2

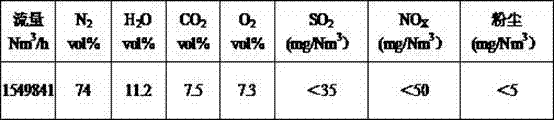

[0034] The flue gas treated in the first stage is stripped of moisture, but the gas contains a large amount of CO 2 , if discharged directly into the atmosphere, it will lead to a large amount of greenhouse gas emissions. CO 2 Captured, stored or rationally utilized, can greatly reduce carbon emissions and achieve CO 2 Turning waste into wealth, so the supersonic swirl capture and treatment system of flue gas can be used to treat CO 2 Perform capture processing.

[0035] 1. Use the compressor 2 to increase the pressure of the flue gas treated in Example 1 to 10 MPa, so as to provide power for the next step of the flue gas to enter the cyclone separation pipe. After the flue gas is pressurized, a pressure difference is formed before and after the first conical tube to allow the gas to flow. The greater the pressure difference, the greater the gas velocity. After passing through the injection expansion section, the temperature drops more (expansion refrigeration), normal pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com