Intermittent planting device for rice transplanter

An intermittent, rice transplanter technology, applied in planting methods, transplanting machinery, agriculture, etc., can solve problems such as unfavorable seedling growth, messy seedling transplanting, and unstable operation of rice transplanters, so as to achieve perfect edge pressing effect and lower ground The effect of unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

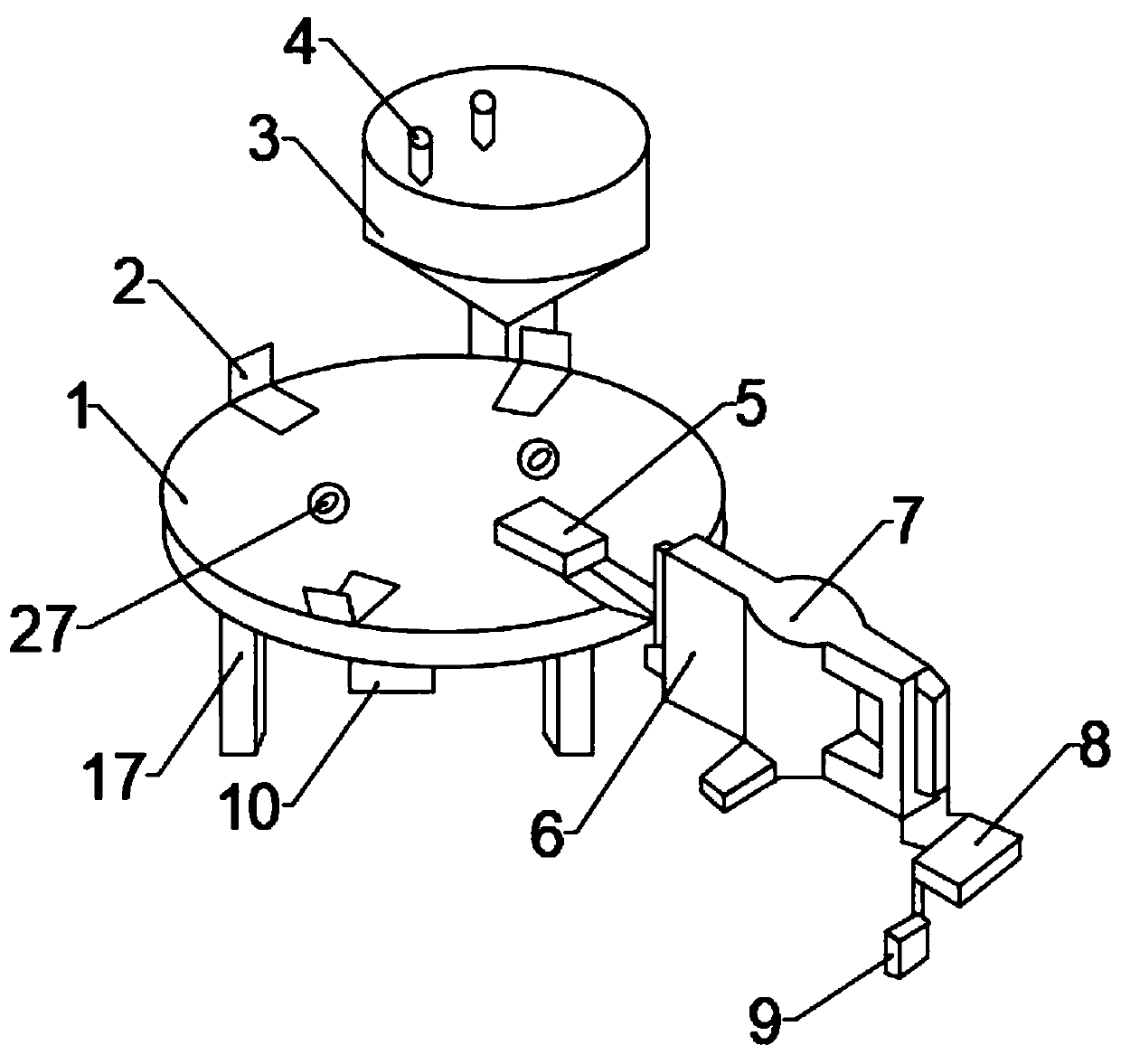

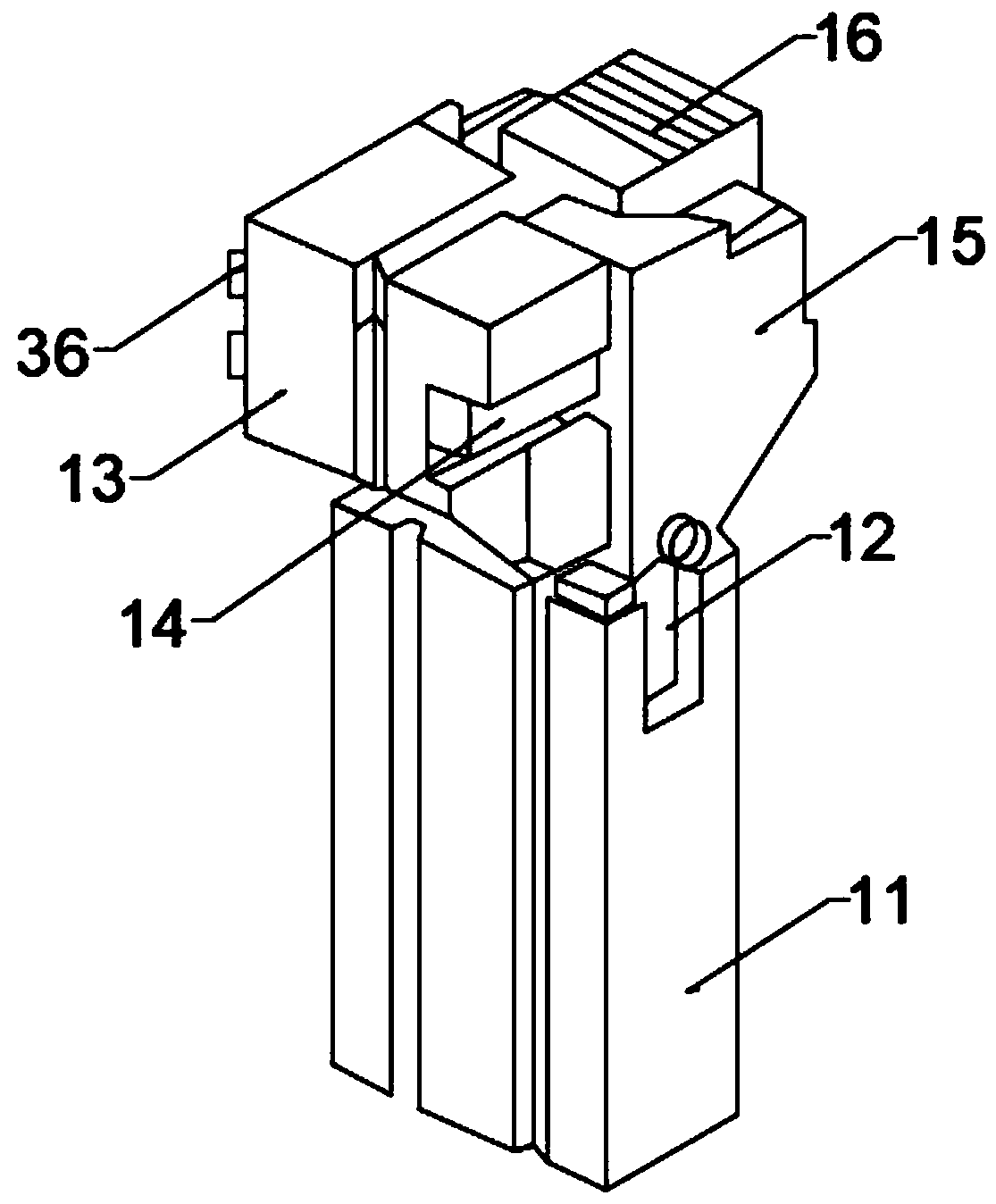

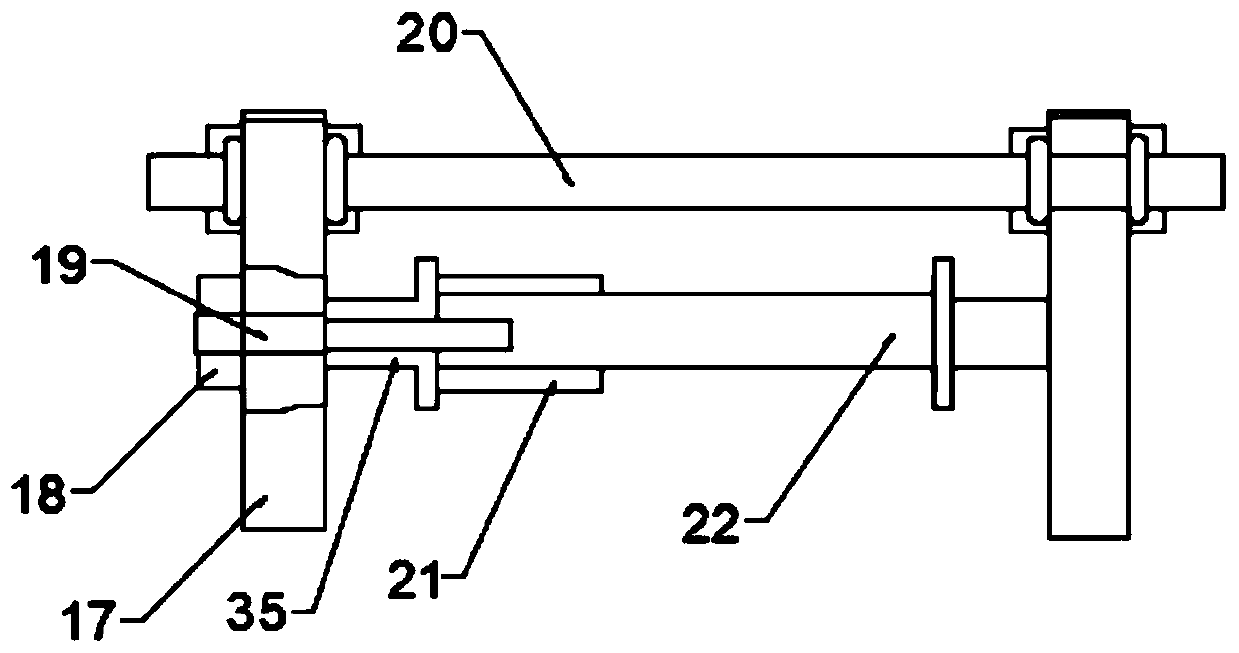

[0027] Such as figure 1 and figure 2 As shown, the present invention provides an intermittent planting device of a rice transplanter, comprising a distribution tray 1 and a mechanical clamping mechanism 10, the upper surface of the distribution tray 1 is fixedly equipped with a plurality of blanking stations 2, And the front end of the distribution tray 1 is connected with the plug-in box 6 through the feeding connecting plate 5, and the plug-in box 6 is fixedly installed on the wire box rotating table 7, and the front part of the wire box rotating table 7 is connected with the hopper 8 , and a terminal machine rotating shaft 9 is provided on the side of the hopper 8, the upper end of the distribution tray 1 is also connected with the vibrating disc 3 through the rotating shaft, and a vibrating motor 4 is also arranged on the upper surface of the vibrating disc 3, The lower surface of the distribution tray 1 is also axially connected with a mechanical clamping mechanism 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com