Testing method for testing building structural materials under thermal-mechanical coupling effect

A technology for building structure and material testing, which is applied in the field of testing, can solve the problems that loading instruments are easy to corrode and occupy land, can not truly reflect impermeability, and the testing methods and devices of building structural materials are less involved, so as to avoid damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

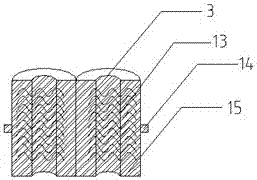

Image

Examples

specific example

[0051] experiment procedure:

[0052] ① MTS 810 material testing system can realize the pre-set load on the specimen in advance, and raise the temperature through the supporting high-temperature equipment under the action of maintaining a constant load. The experimental method of presetting the load first and then raising the temperature can simulate the real situation that the concrete structure material has been loaded in the actual fire. During the heating process, the system can accurately record the thermal expansion displacement and heating time of the concrete material, which is beneficial to analyze the variation law of the thermal expansion of the concrete material under the action of high temperature load with the heating time.

[0053] ② After the concrete material is thermally expanded at high temperature, the bearing capacity performance of the concrete material under high temperature load can be studied. The concrete specimen under high temperature load is subj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com