Backlight luminosity and heat dissipation detection device

A testing equipment and backlight technology, which is applied in the testing of optical instruments, measuring devices, and testing of machine/structural components, etc., can solve the problems of large error in testing results, inability to observe internal conditions, slow heat dissipation, etc. The effect of detection error, improved detection accuracy and high airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

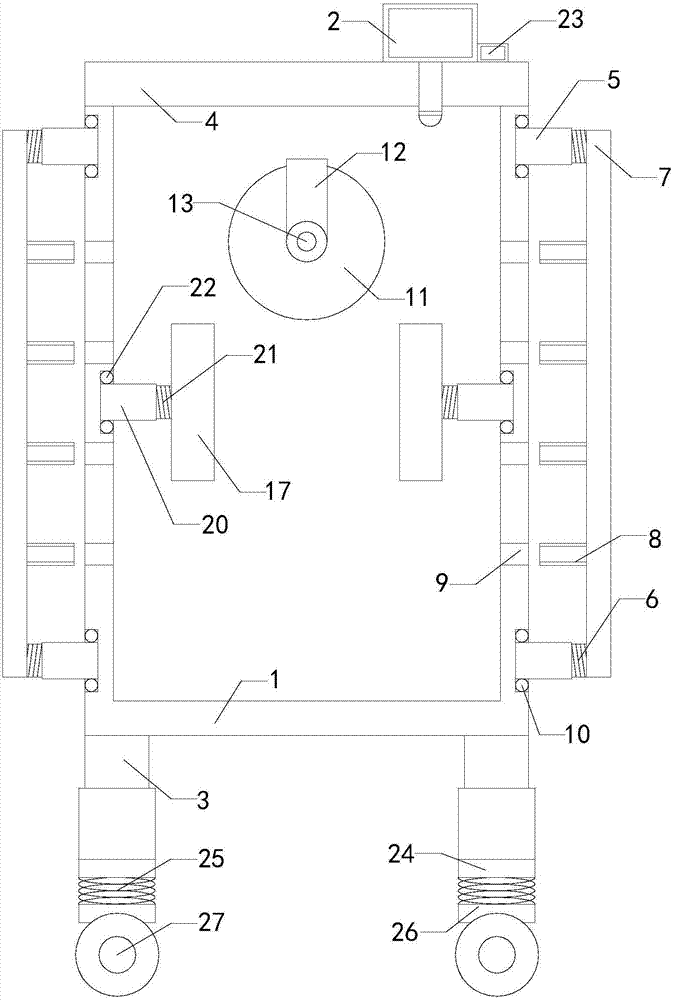

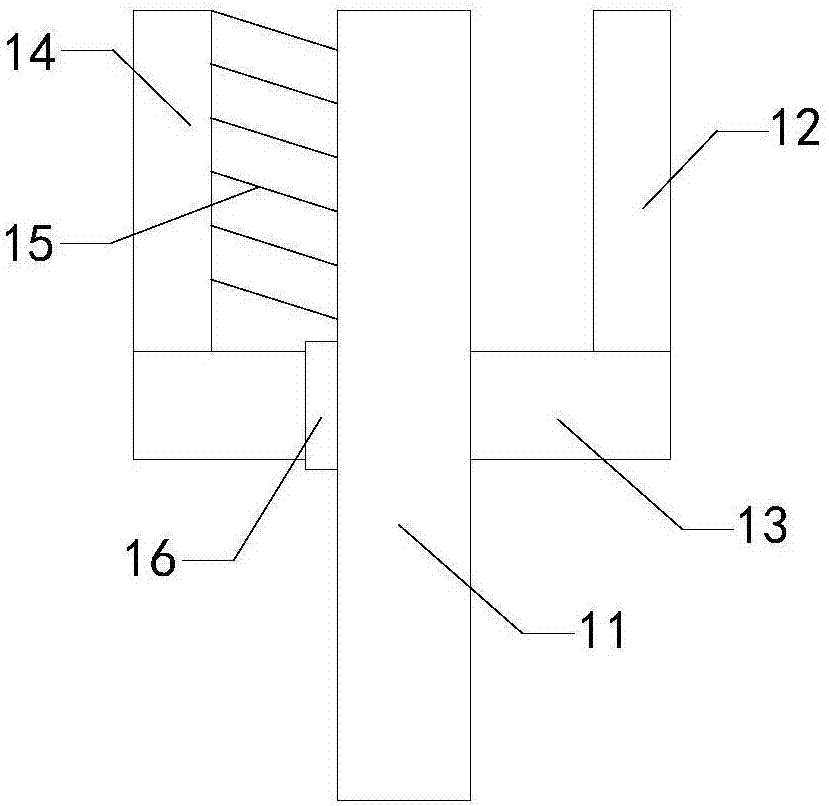

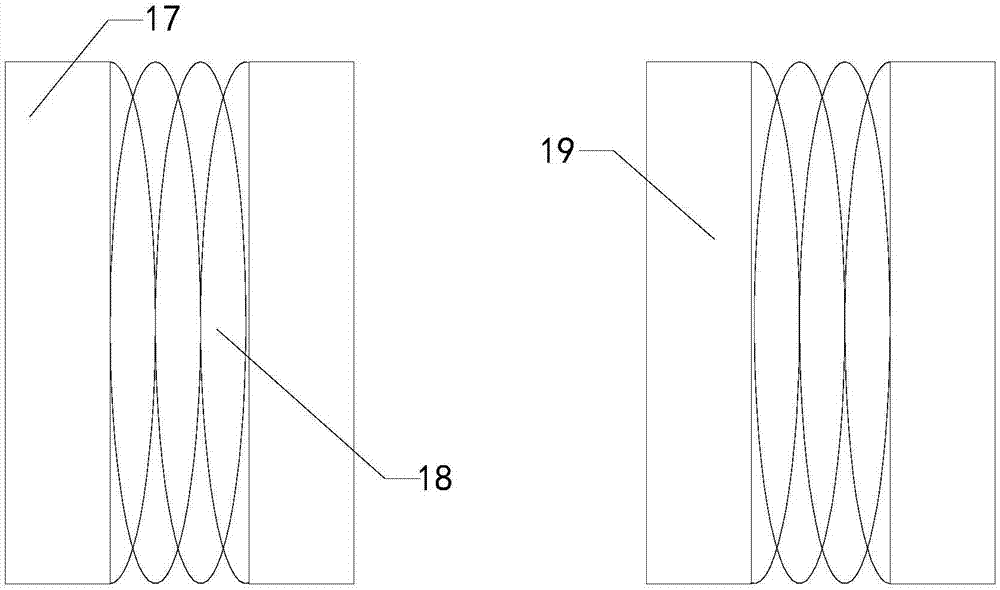

[0015] Such as Figure 1 to Figure 3 As shown, a kind of backlight luminous heat radiation detection equipment of the present invention comprises a working box 1, a detector 2 and four sets of supports 3, a working chamber is arranged inside the working box, and a pick-and-place opening is arranged on the top of the working box, and A cover 4 is provided at the access opening, and the tops of the four sets of brackets are respectively installed on the left front, right front, left rear and right rear of the bottom of the work box. The cover extends into the working chamber; it also includes two sets of first left-threaded tubes, two sets of first left-threaded rods, a lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com