Stress peak detection method through laser shock peening hole wall

A laser shock strengthening, stress peak technology, applied in force/torque/work measuring instruments, measuring devices, instruments, etc., can solve the problems of unpredictable strengthening effect of small hole components, difficult process control, cumbersome and other problems, to achieve online Monitoring and real-time control, solving measurement difficulties, and detecting the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

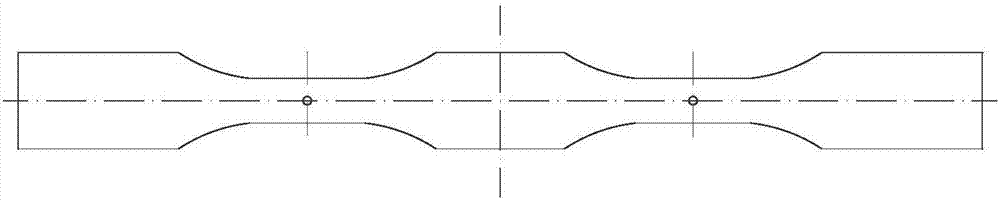

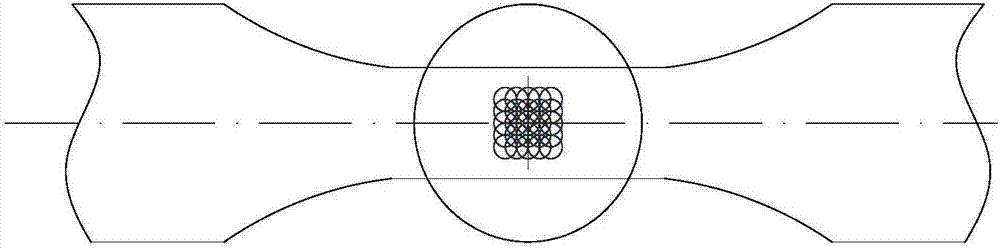

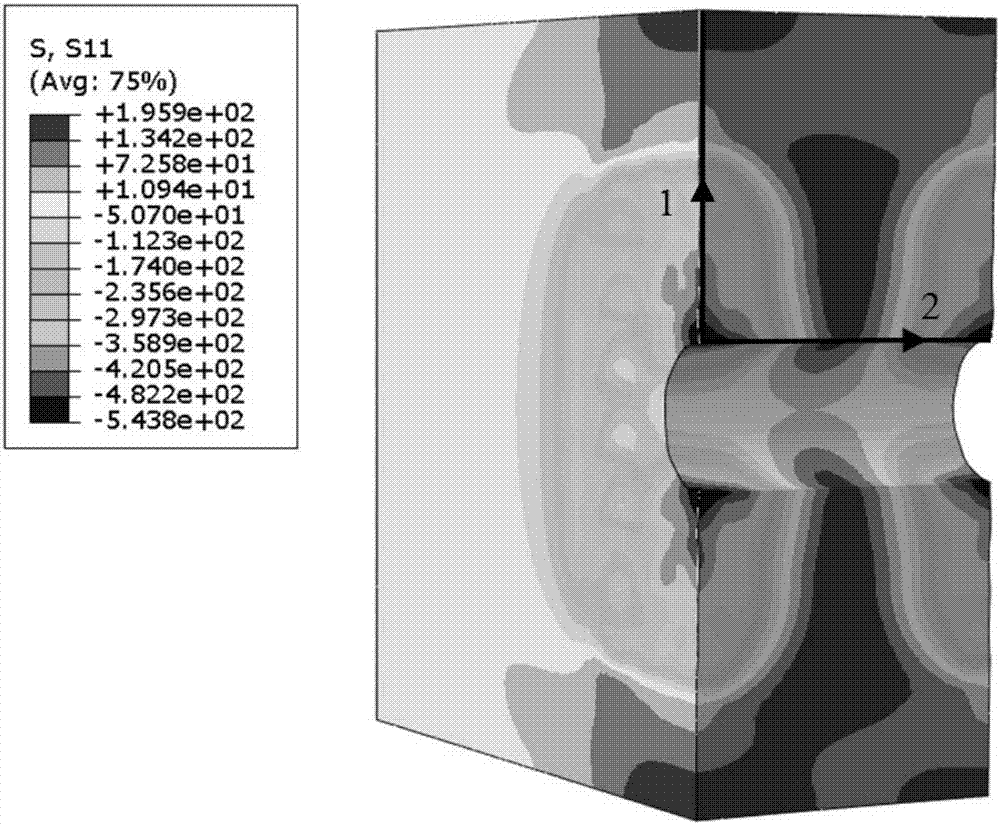

[0057] S01: Establish the finite element model of the laser shock strengthening hole; specifically, define the geometric model of the sample, select the unit, divide the mesh, set the laser shock action area, select the material constitutive model and parameters, and impose boundary constraints;

[0058] In the simulation software ABAQUS, the Y-axis is used as the thickness direction of the model, and the X-Z plane is the laser shock plane to create a geometric model of a rectangular small block. The type of grid division is the explicit linear reduced integration unit C3D8R, and the grid division process In order to carry out mesh refinement in the area of 2 times the length of the spot radius on the three coordinate axes; the mesh division process is to carry out mesh refinement in the area of 2 times the length of the spot radius on the three coordinate axes; the material constitutive model uses Johnson -Cook model; said imposing boundary conditions is imposing symmetry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com