A comprehensive utilization method for harmless disposal of high-salt chemical sludge

A technology of chemical sludge and high salt content, applied in chemical instruments and methods, water/sludge/sewage treatment, combustion methods, etc., can solve the problems of destroying surrounding vegetation, difficult to clean impurities, secondary pollution, etc., and achieve The effect of low equipment use cost, simple structure, easy maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

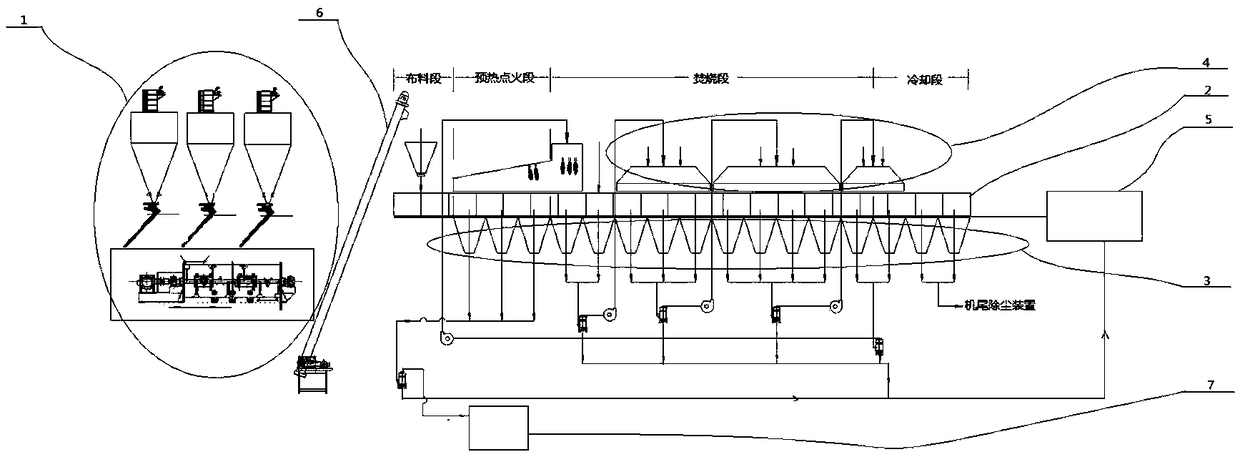

[0043] Example 1 Negative pressure cycle thermal storage incineration recovery equipment

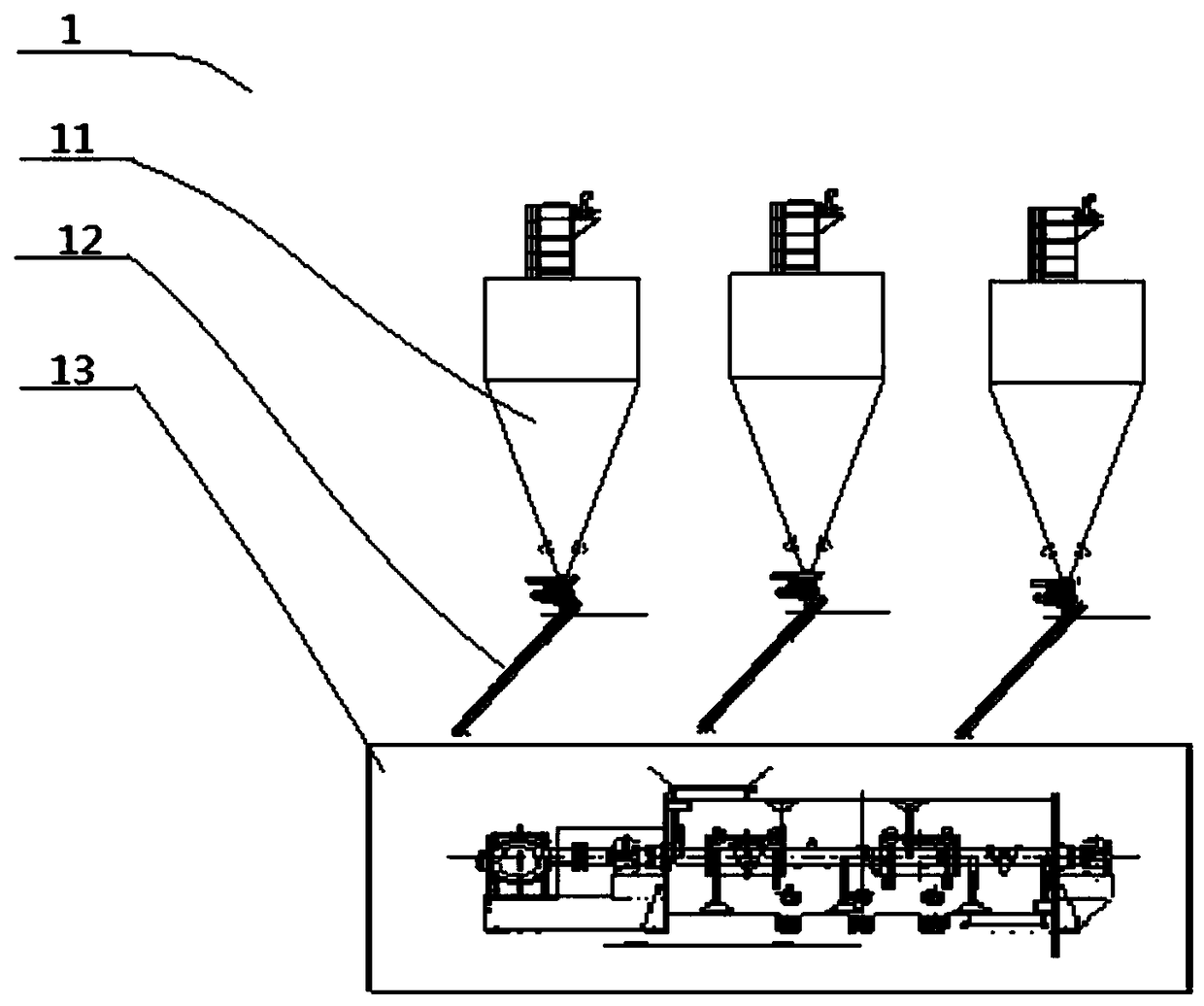

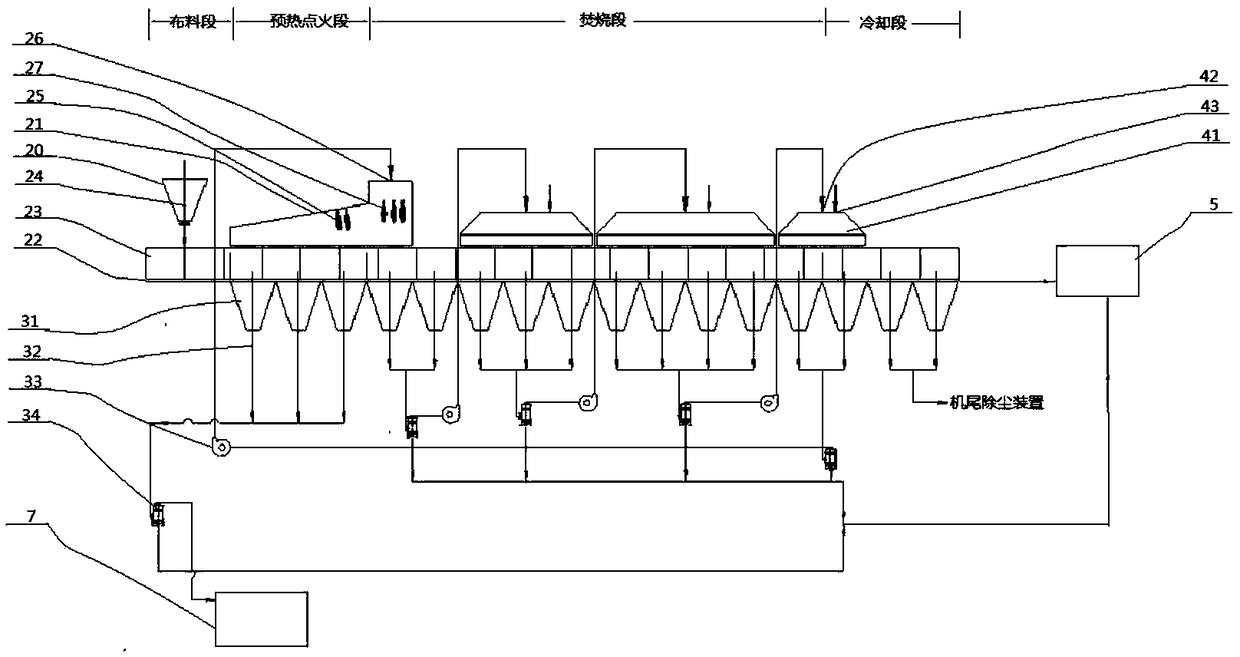

[0044] Such as Figure 1-5 As shown, the negative pressure cycle heat storage incineration recovery equipment of the present invention includes a mixing system 1, a trolley type incineration system 2, an exhaust system 3, a flue gas circulation system 4, a salt recovery system 5, a transmission system 6 and a flue gas purification system 7 , the mixing system 1 includes a plurality of silos 11, a metering scale 12, and a mixing and stirring device 13. The discharge port of the silo 11 is aligned with the weighing pan of the weighing scale 12, and the weighing pan of the weighing scale 12 Corresponding to the feed port of the mixing and stirring device 13, the discharge port of the mixing and stirring device 13 is connected to the transmission system 6, and the lime, chaff and biomass fuel in the silo 11 are weighed by the metering scale 12, and then sent to the mixing and stirring device...

Embodiment 2

[0050] Example 2 Comprehensive Utilization of High Salt Chemical Sludge

[0051] Step 1: crush the high-salt chemical sludge to a particle size of 3-12mm, mix the sludge with lime, chaff, and biomass fuel at a mass ratio of 45:5:15:35 to prepare a mixture, and the chaff The particle size of the biomass fuel is 2-8mm, the particle size of the biomass fuel is 1-8mm, and the calorific value is 5000 kcal;

[0052] Step 2: The mixture obtained in step 1 is sent into the trolley type incineration system of the negative pressure cycle heat storage incineration recovery equipment described in Example 1, the thickness of the mixture is 500mm, and the advancing speed of the mixture is 0.16m / s. Ignition and incineration, the waste gas discharged by the flue gas purification device 7 meets the EU 2000 standard, the salt recovery rate is 90%, and the purity (organic content) is less than 1%.

Embodiment 3

[0053] Example 3 Comprehensive Utilization of High Salt Chemical Sludge

[0054] Step 1: crush the high-salt chemical sludge to a particle size of 4-10mm, mix the sludge with lime, chaff, and biomass fuel at a mass ratio of 60:2:10:28 to prepare a mixture, and the chaff The particle size of the biomass fuel is 2-8mm, the particle size of the biomass fuel is 1-8mm, and the calorific value is 5000 kcal;

[0055] Step 2: The mixture obtained in step 1 is sent into the trolley type incineration system of the negative pressure circulation heat storage incineration recovery equipment described in Example 1, the thickness of the mixture is 700mm, and the advancing speed of the mixture is 0.08m / s. Ignition and incineration, the exhaust gas discharged by the flue gas purification device 7 meets the EU 2000 standard, the salt recovery rate is 92%, and the purity (organic content) is less than 1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com