Electric control hydraulic actuating mechanism of direct-drive clutch of motor and method for controlling electric control hydraulic actuating mechanism

An electronically controlled hydraulic and actuator technology, which is applied in the field of automobile transmission, can solve problems such as application restrictions of low-end and low-end automobiles, hidden dangers of reliability and safety, and production difficulties, and achieve the effects of energy saving, environmental protection, stable integration, and rapid separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

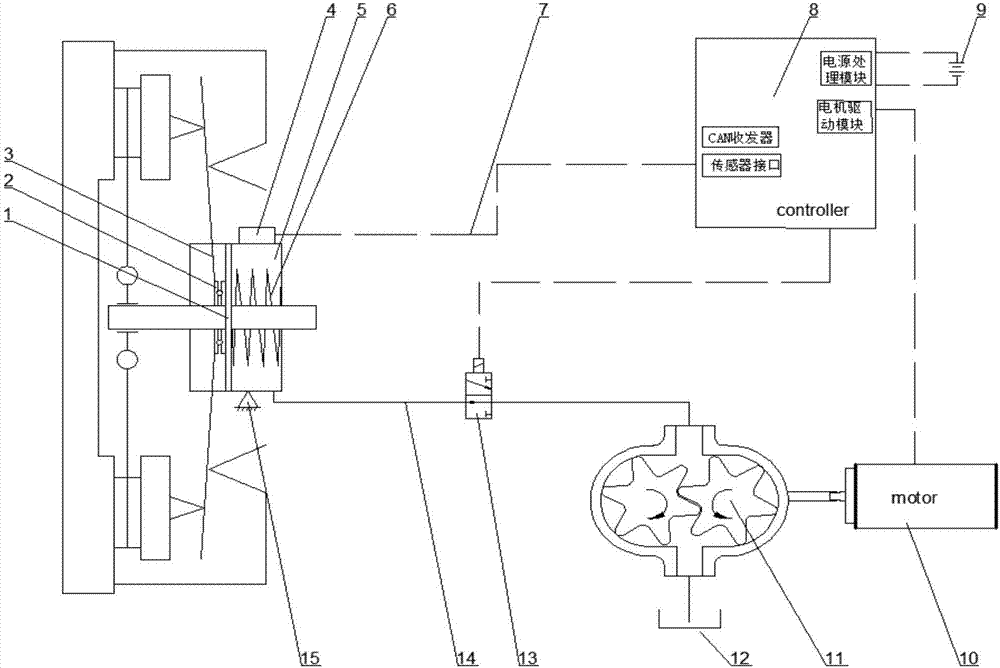

[0033] In order to further illustrate the technical solution of the present invention, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

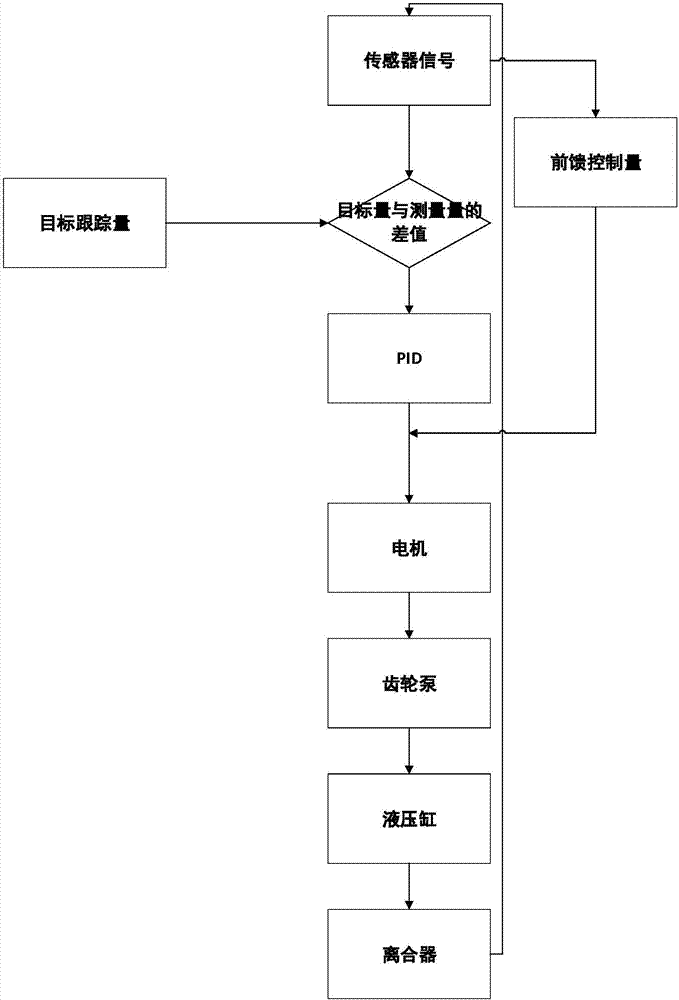

[0034] Such as figure 1 As shown, the present invention provides a motor direct drive type clutch electro-hydraulic actuator, and the actuator is composed of a mechanical assembly and an electric control assembly.

[0035] The mechanical assembly includes a clutch release bearing 2 , a hydraulic cylinder 5 , a return spring 6 , a DC motor 10 , a gear pump 11 , an oil reservoir 12 , a switching valve 13 , a hydraulic oil pipe 14 and a support 15 .

[0036] The DC motor 10 is fixed on the support 15 by fastening bolts; the gear pump 11 is also fixed on the support by fastening bolts, and the gear pump 11 is a medium-low pressure small displacement gear pump.

[0037] The output shaft of the DC motor 10 is coaxially connected with the input shaft of the gear pump 11 through a sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com