Independent presser foot control mechanism of embroidery machine

A technology of a control mechanism and an embroidery machine, which is applied in the field of embroidery machines, and can solve the problems of difficult individual adjustment of the initial stroke of the presser foot, poor applicability of different fabrics, and large impact of the fabric, so as to improve the quality of embroidery, improve adaptability, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

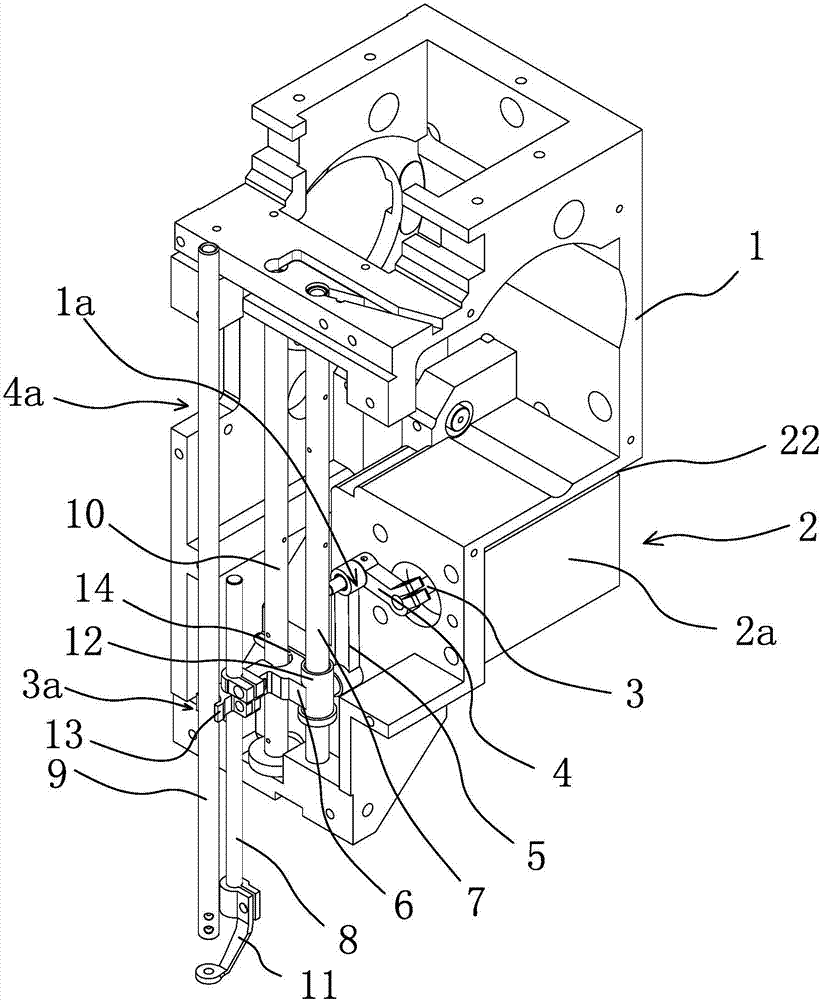

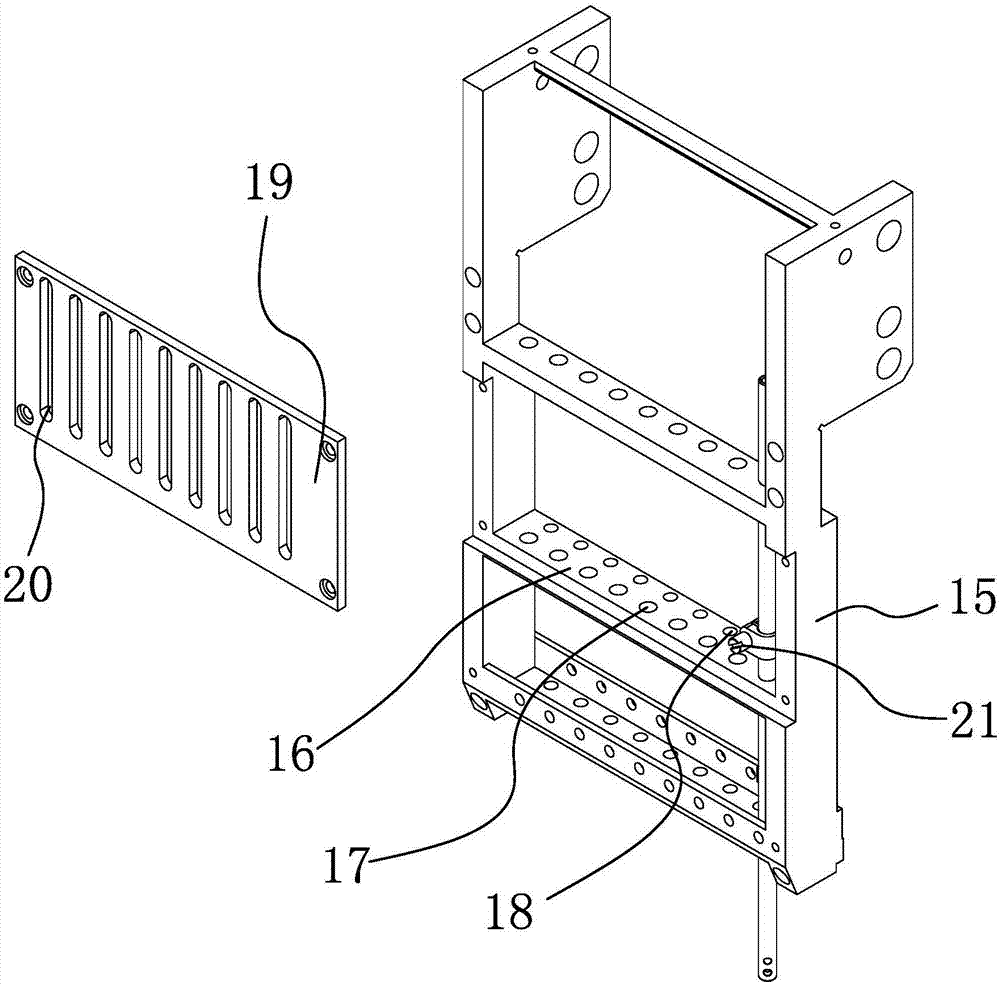

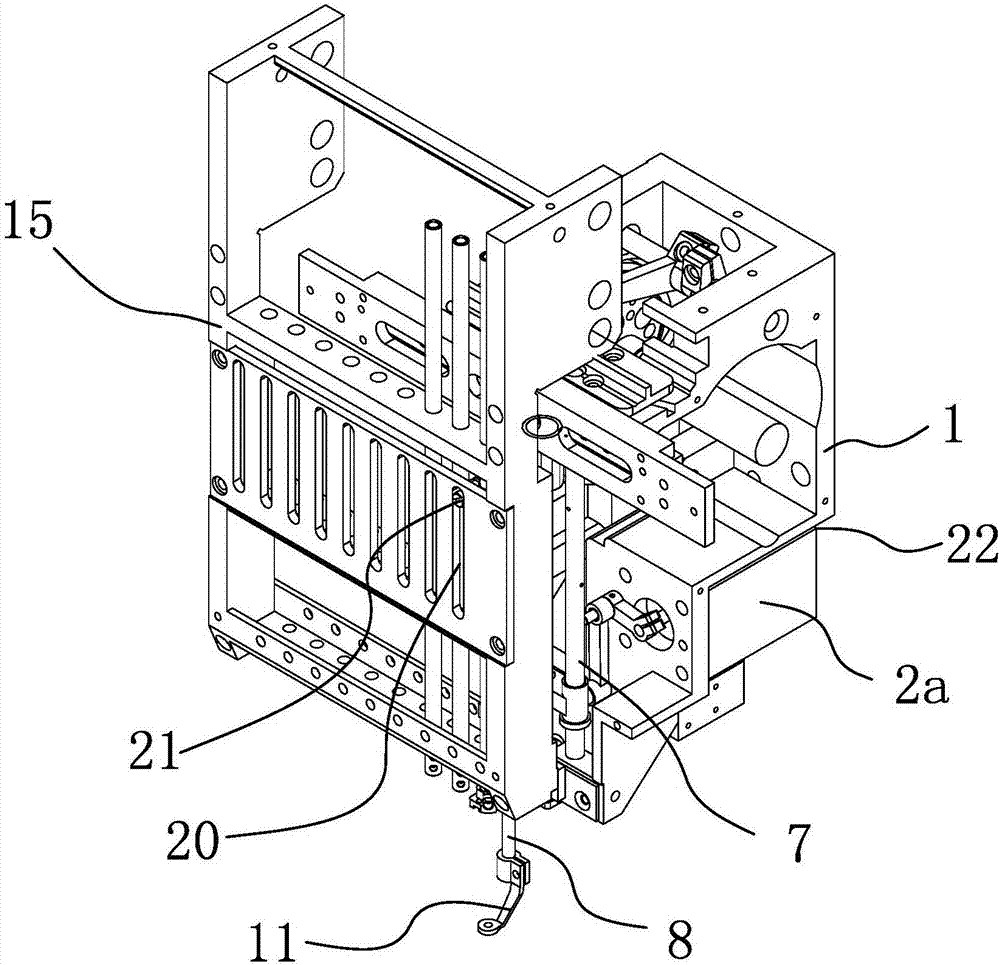

[0022] Such as Figure 1-3 As shown, the independent presser foot control mechanism of this embroidery machine includes a headstock 1, and a drive mechanism 2 is arranged on the headstock 1. The drive mechanism 2 is connected with a presser foot drive seat 6 through a connecting rod transmission structure 1a, and the presser foot is driven The seat 6 is movably sleeved on the presser foot driving rod 7 which is fixedly connected to the headstock 1, and one end of the presser foot driving seat 6 is connected with a presser foot driving seat 6 which can move up and down along the axial direction of the presser foot driving rod 7 to follow the pressure. The presser foot needle bar 8 that moves synchronously with the foot driving seat 6 is connected with the presser foot 11, and the circumferential outer side of the presser foot driving seat 6 is also connected with the presser foot driving seat 6 through the rod body positioning structure 3a. The needle bar assembly 4a is movable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com