Thread hooking device for preventing deformation of pull rod and embroidery machine

A thread catcher and pull rod technology, which is applied in the field of thread catcher, can solve the problems of torsion spring failure, ball detachment, etc., and achieve the effects of stable thread hooking action, increased rotational resistance, and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

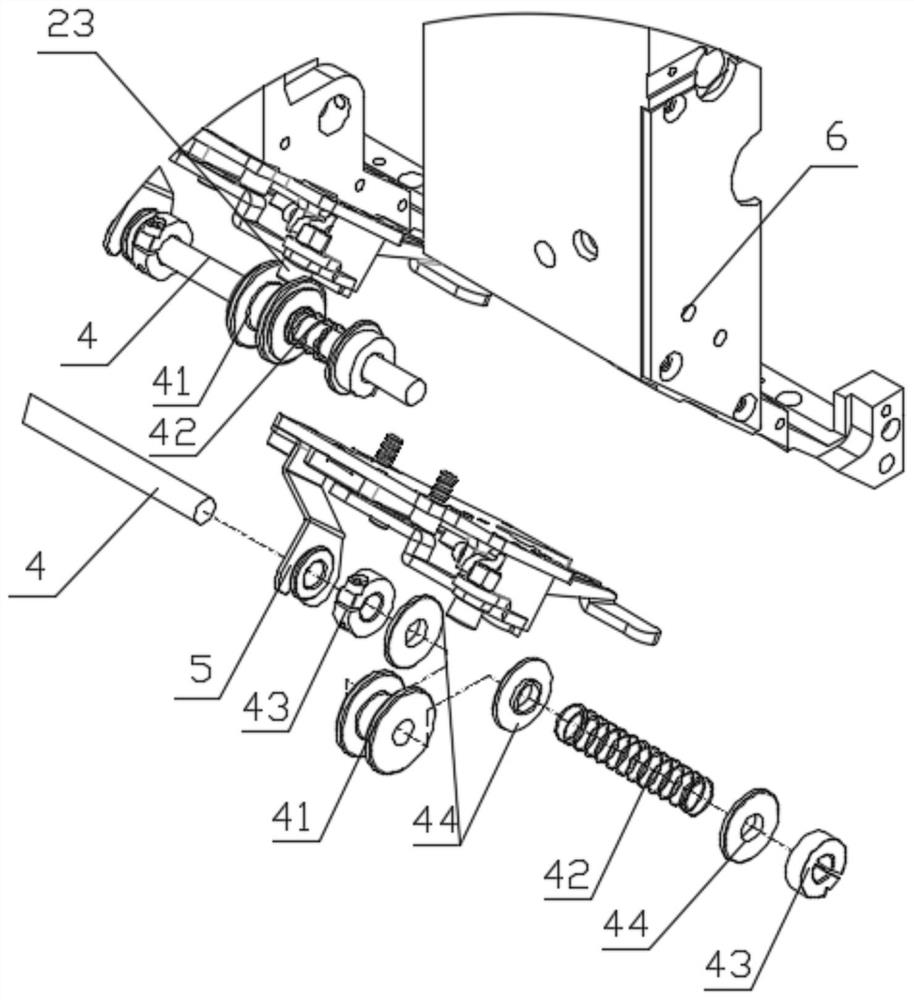

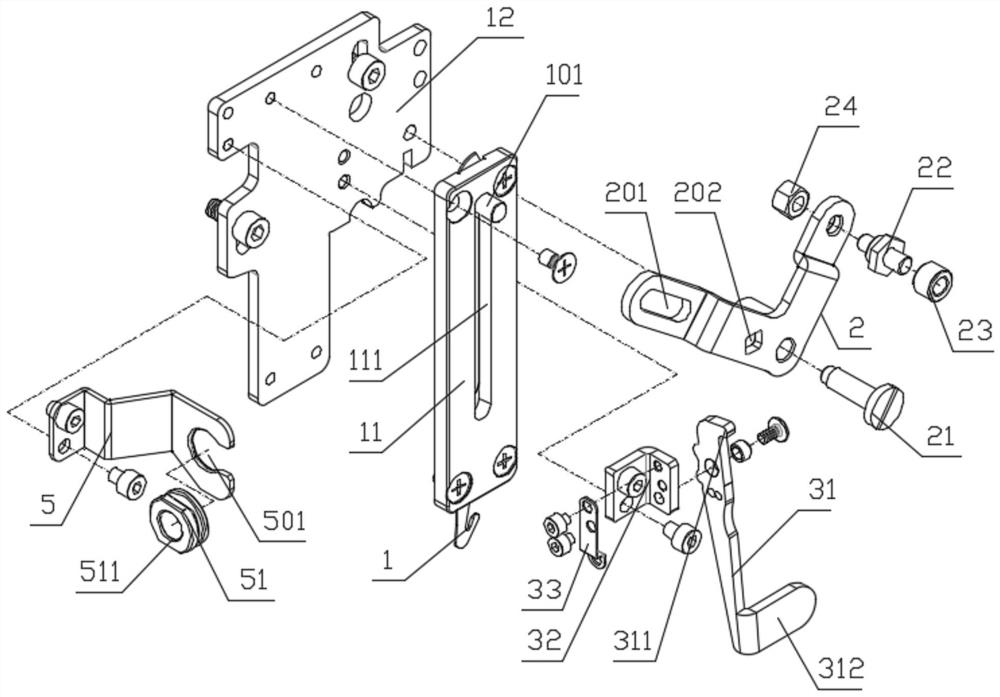

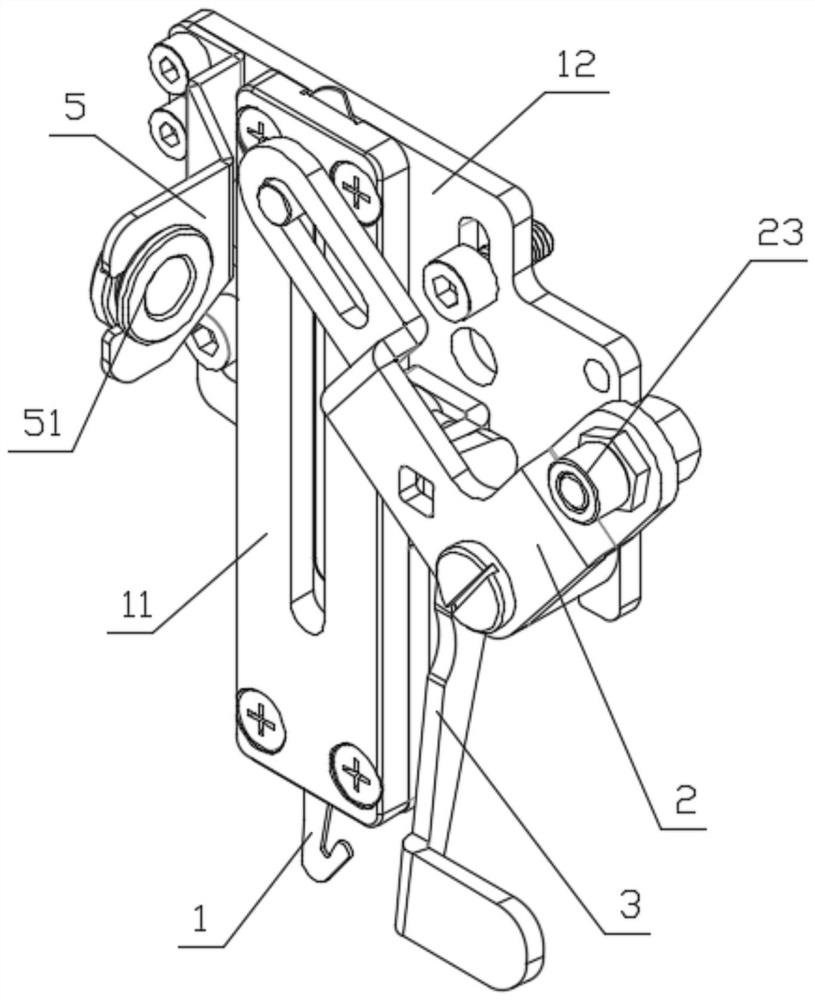

[0032] Such as Figure 1 to Figure 3 As shown, the hooking device includes a hooking driver, a hooking rod 4, a hooking fork 2 and a hooking knife 1. The hooking driver drives the hooking rod 4 to reciprocate in a straight line, and the hooking rod 4 is rotatably connected with a ball guide Block 41, the ball guide block 41 is provided with a ball guide groove arranged in a ring around the wire hooking rod 4, the wire hooking shift fork 2 is provided with a ball 23, and the ball guide block 41 is driven by the wire hooking rod 4 to move linearly to and fro , the ball 23 rolls in the ball guide groove to make the line-hooking shift fork 2 swing back and forth, and the line-hooking shift fork 2 drives the hook knife 1 to linearly reciprocate to realize the line-hooking. After the ball 23 rolls in the ball guide groove, no matter how the ball guide block rotates with respect to the thread-drawing pull bar, the ball is still in the ball guide groove and will not disengage.

[003...

Embodiment 2

[0046] An embroidery machine, comprising the thread catcher in the above embodiment, such as figure 1 As shown, the thread catcher is installed on the embroidery machine head housing 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com