A high-strength aluminum alloy with excellent oxidation effect and its preparation method and application

An aluminum alloy, high-strength technology, applied in the field of high-strength aluminum alloy and its preparation, can solve the problems of application limitation, insufficient attention to the effect of anodization, and inability to be universal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

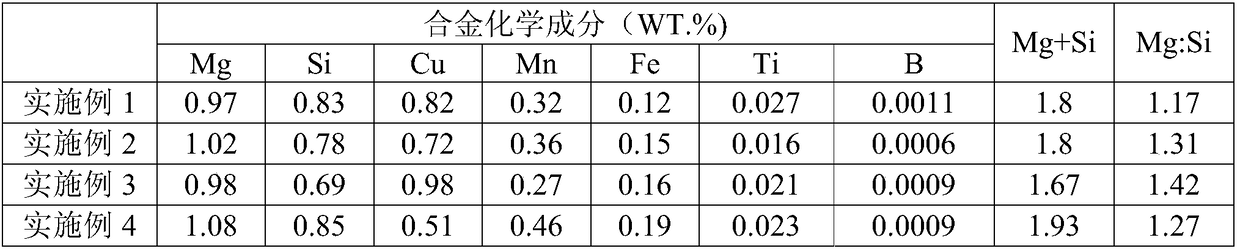

Embodiment 1

[0070]1. The chemical composition of the high-strength Al-Mg-Si-Cu alloy according to the excellent anodic oxidation effect is calculated by mass percentage: Mg is 0.97%, Si is 0.83%, Cu is 0.82%, Mn is 0.32%, and Fe is 0.12% %, Ti is 0.027%, B is 0.0011%, the total amount of other impurities is <0.15%, and the balance is Al for material preparation.

[0071] 2. Preparation method:

[0072] The first step: select aluminum ingots with a purity of ≥99.9%, magnesium ingots with a purity of ≥99.95%, and Al-20Cu, Al-12Si, Al-20Mn master alloys, Al-5Ti-0.2B alloy rods (grain refiner) as a raw material;

[0073] Step 2: Heat and melt the aluminum ingot at 750-760°C, add magnesium ingot and intermediate alloy according to the above mass percentage, stir and melt to form aluminum alloy liquid;

[0074] Step 3: According to the ratio of 0.5 kg of refining agent / ton of aluminum alloy liquid, the refining agent is sprayed with high-purity argon with a purity ≥ 99.99% to refine the alumi...

Embodiment 2

[0082] 1. The chemical composition of the high-strength Al-Mg-Si-Cu alloy according to the excellent anodic oxidation effect is calculated by mass percentage: Mg is 1.02%, Si is 0.78%, Cu is 0.72%, Mn is 0.36%, and Fe is 0.15% %, Ti is 0.016%, B is 0.0006%, the total amount of other impurities is <0.15%, and the balance is Al for material preparation.

[0083] 2. Preparation method:

[0084] Step 1: Select aluminum ingots with a purity of ≥99.9%, magnesium ingots with a purity of ≥99.95%, and Al-20Cu, Al-12Si, Al-20Mn master alloys, and Al-5Ti-0.2B alloy rods as raw materials;

[0085] Step 2: Heat and melt the aluminum ingot at 730-740°C, add magnesium ingot and intermediate alloy according to the above mass percentage, stir and melt to form aluminum alloy liquid;

[0086] The third step: according to the ratio of 2 kg of refining agent / ton of aluminum alloy liquid, the refining agent is sprayed with high-purity argon gas with a purity ≥ 99.99% to refine the aluminum alloy l...

Embodiment 3

[0094] 1. The chemical composition of the high-strength Al-Mg-Si-Cu alloy according to the excellent anodic oxidation effect is calculated by mass percentage: Mg is 0.98%, Si is 0.69%, Cu is 0.98%, Mn is 0.27%, and Fe is 0.16% %, Ti is 0.021%, B is 0.0009%, the total amount of other impurities is <0.15%, and the balance is Al for material preparation.

[0095] 2. Preparation method:

[0096] Step 1: Select aluminum ingots with a purity of ≥99.9%, magnesium ingots with a purity of ≥99.95%, and Al-20Cu, Al-12Si, Al-20Mn master alloys, and Al-5Ti-0.2B alloy rods as raw materials;

[0097] Step 2: Heat and melt the aluminum ingot at 742-755°C, add magnesium ingot and intermediate alloy according to the above mass percentage, stir and melt to form aluminum alloy liquid;

[0098] Step 3: According to the ratio of 1.5 kg of refining agent / ton of aluminum alloy liquid, use high-purity argon gas with a purity of ≥99.99% to blow the refining agent to refine the aluminum alloy liquid fo...

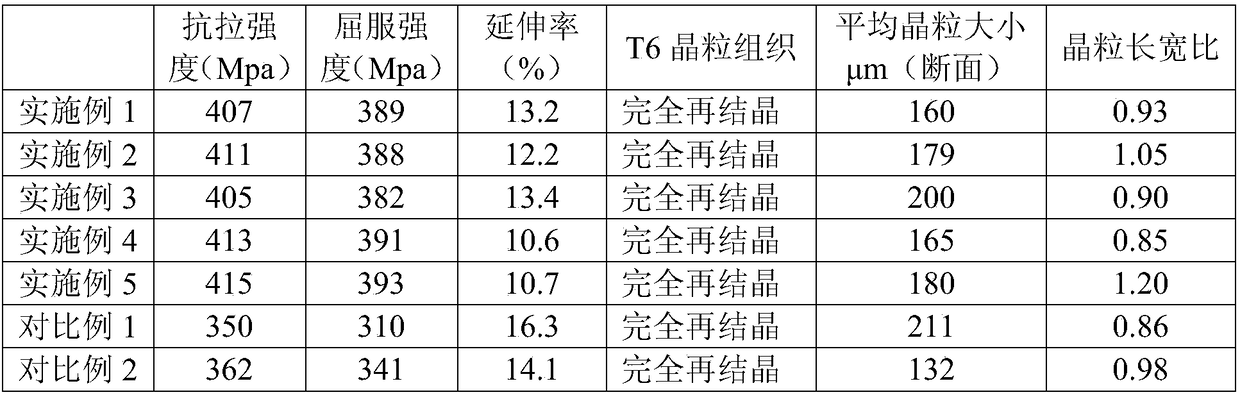

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com