A kind of preparation method of cellulose/chitosan-based nano fresh-keeping drug-loaded sponge

A technology of chitosan and cellulose, which is applied in the field of food packaging materials, can solve the problems that the antiseptic and antibacterial properties cannot be fully exerted, and the excellent properties are discounted, so as to achieve good loading and controlled release capacity, delay corruption, and important social and economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

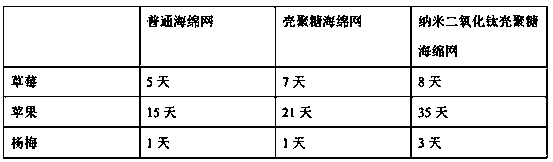

Image

Examples

Embodiment 1

[0019] (1) Take sodium carboxymethyl cellulose and chitosan powder according to the mass ratio of 2:1; wherein the degree of substitution of sodium carboxymethyl cellulose is 0.7, the degree of deacetylation of chitosan is 50%, and carboxymethyl Sodium cellulose was dissolved in distilled water to form a 2% sodium carboxymethylcellulose solution, chitosan was dissolved in acetic acid solution to form a chitosan solution with a concentration of 1.5%, and the pH of the two solutions was adjusted with hydrochloric acid to 1.0;

[0020] (2) Blend the two solutions in step (1), add nano-titanium dioxide, bentonite, glycerin, stir evenly, and let it stand for defoaming; wherein, the particle size of nano-titanium dioxide is 60 nm, and the amount added is 1% of the total dry matter. %, the density of bentonite is 2~3g / cm3, the amount added is 6% of the total dry matter, and the amount of glycerin added is 4% of the total dry matter;

[0021] (3) Pour the mixed liquid obtained in ste...

Embodiment 2

[0023] (1) Take sodium carboxymethyl cellulose and chitosan powder according to the mass ratio of 3:1; wherein the degree of substitution of sodium carboxymethyl cellulose is 0.8, the degree of deacetylation of chitosan is 60%, and the carboxymethyl Sodium cellulose was dissolved in distilled water to form a 2% sodium carboxymethylcellulose solution, chitosan was dissolved in acetic acid solution to form a chitosan solution with a concentration of 1.5%, and the pH of the two solutions was adjusted with hydrochloric acid to 1.0;

[0024] (2) Blend the two solutions in step (1), add nano-titanium dioxide, bentonite, glycerin, stir evenly, and let it stand for defoaming; wherein, the particle size of nano-titanium dioxide is 150 nm, and the amount added is 4% of the total dry matter. %, the bentonite density is 2~3g / cm3, the addition is 4% of the total dry matter, and the glycerin addition is 4% of the total dry matter;

[0025] (3) Pour the mixed liquid obtained in step (2) int...

Embodiment 3

[0027] (1) Take sodium carboxymethyl cellulose and chitosan powder according to the mass ratio of 4:1; wherein the degree of substitution of sodium carboxymethyl cellulose is 0.7, the degree of deacetylation of chitosan is 50%, and carboxymethyl Sodium cellulose was dissolved in distilled water to form a 2% sodium carboxymethylcellulose solution, chitosan was dissolved in acetic acid solution to form a chitosan solution with a concentration of 1.5%, and the pH of the two solutions was adjusted with hydrochloric acid to 1.0;

[0028] (2) Blend the two solutions in step (1), add nano-titanium dioxide, bentonite, glycerin, stir evenly, and let it stand for defoaming; wherein, the particle size of nano-titanium dioxide is 60 nm, and the amount added is 7% of the total dry matter. %, the density of bentonite is 2~3g / cm3, the amount added is 2% of the total dry matter, and the amount of glycerin added is 4% of the total dry matter;

[0029] (3) Pour the mixed liquid obtained in ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com