A kind of purification separation method of sucrose fatty acid ester

A technology of sucrose fatty acid ester and separation method, which is applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problems of large solvent usage, complicated process, high refining cost, etc., and achieve easy recycling and recycling , The process is simple, the effect of high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A method for purifying and separating sucrose fatty acid esters, comprising the following steps:

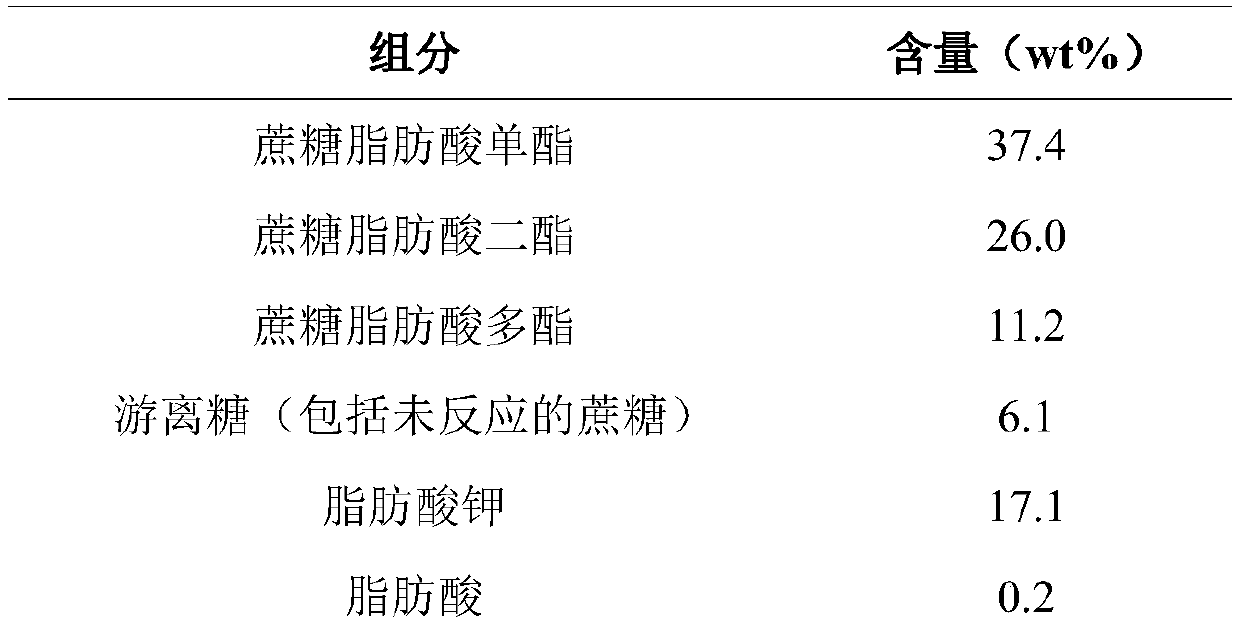

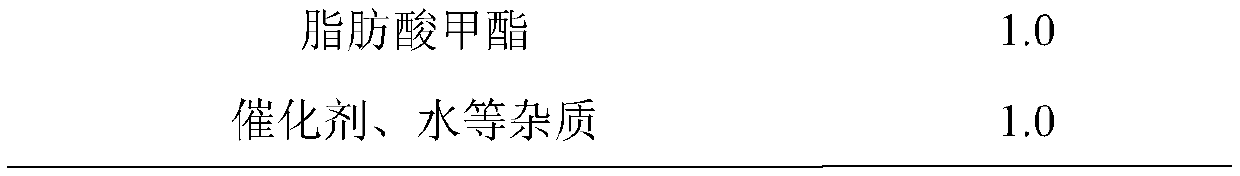

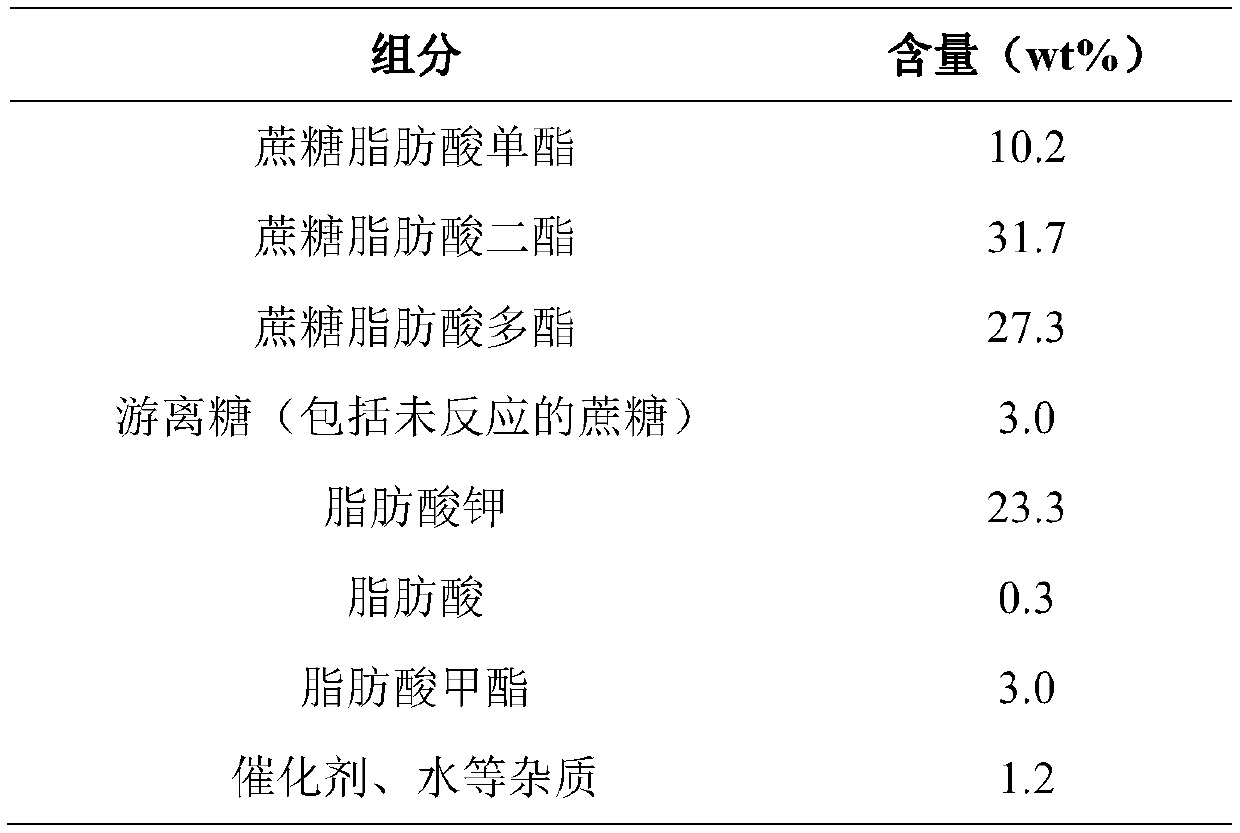

[0046] 1) Take 100 g of the sucrose fatty acid ester mixture shown in Table 1, add 200 mL of tetrahydrofuran, stir at 35° C. and 500 rpm for 30 min, filter and separate to obtain solid residue and sucrose fatty acid ester mother liquor;

[0047] 2) Add 1800mL of methanol to the sucrose fatty acid ester mother liquor, place it at 0°C for 120min, filter and separate to obtain filtrate A and solid B, filtrate A is distilled under reduced pressure to recover the organic solvent, and dry in vacuum to obtain 41.5g of sucrose fatty acid ester product I (wherein, the total content of sucrose fatty acid ester is 94.6%, monoester content is 88.6%, and diester and polyester content are 6.0%), solid B is through vacuum drying, obtains 32.3g sucrose fatty acid ester product II (wherein, The total content of sucrose fatty acid ester>99%, the content of monoester is 1.5%, and the content...

Embodiment 2

[0049]A method for purifying and separating sucrose fatty acid esters, comprising the following steps:

[0050] 1) Take 100 g of the sucrose fatty acid ester mixture shown in Table 1, add 200 mL of tetrahydrofuran, stir at 35° C. and 500 rpm for 30 min, filter and separate to obtain solid residue and sucrose fatty acid ester mother liquor;

[0051] 2) Add 800mL of methanol to the sucrose fatty acid ester mother liquor, place it at 0°C for 120min, filter and separate to obtain filtrate A and solid B, filtrate A is distilled under reduced pressure to recover the organic solvent, and dry in vacuum to obtain 45.5g of sucrose fatty acid ester product I (Wherein, the total content of sucrose fatty acid ester is 95.2%, monoester content is 75.2%, diester and polyester content are 20%), solid B is through vacuum drying, obtains 28.5g sucrose fatty acid ester product II (wherein, The total content of sucrose fatty acid ester>99%, the content of monoester is 7.7%, and the content of die...

Embodiment 3

[0053] A method for purifying and separating sucrose fatty acid esters, comprising the following steps:

[0054] 1) Take 100 g of the sucrose fatty acid ester mixture shown in Table 1, add 400 mL of tetrahydrofuran, stir at 20° C. and 300 rpm for 30 min, filter and separate to obtain the solid residue and sucrose fatty acid ester mother liquor;

[0055] 2) Add 1200mL of methanol to the sucrose fatty acid ester mother liquor, place it at 20°C for 30min, filter and separate to obtain filtrate A and solid B, filtrate A is distilled under reduced pressure to recover the organic solvent, and dry in vacuo to obtain 53.4g of sucrose fatty acid ester product I (Wherein, the total content of sucrose fatty acid ester is 95.5%, monoester content is 67.4%, diester and polyester content are 28.1%), solid B is through vacuum drying, obtains 22.7g sucrose fatty acid ester product II (wherein, The total content of sucrose fatty acid ester>99%, the content of monoester is 5.3%, and the content...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com