Method for preparing vinyl magnesium chloride

A technology of vinyl magnesium chloride and vinyl chloride, applied in the direction of magnesium organic compounds, etc., can solve the problems of slow solvent absorption rate, low vinyl chloride concentration, hidden dangers in production safety, etc., achieve accurate yield and concentration, and improve concentration and yield. , the effect of increasing solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

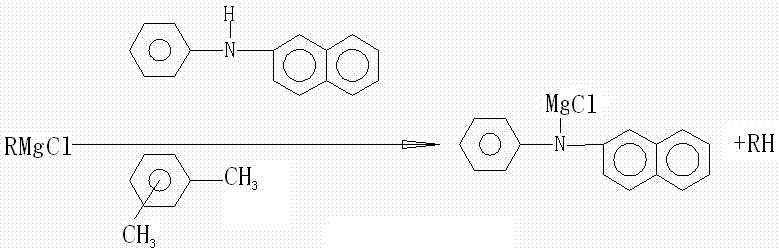

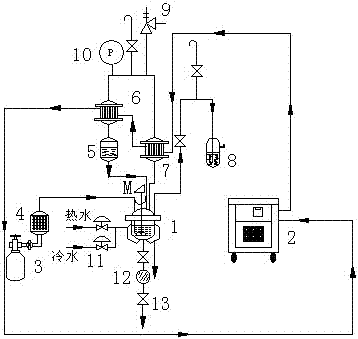

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: prepare vinylmagnesium chloride according to the following specific steps

[0023] (1) Treatment of magnesium chips: take a certain amount of magnesium chips, act for several minutes with a 5% hydrochloric acid solution with a mass concentration, remove the acid solution by suction filtration, wash with water, ethanol, tetrahydrofuran successively, drain and put in a desiccator for subsequent use;

[0024] (2) Check whether there is peroxide in tetrahydrofuran: mix tetrahydrofuran reagent with an equal volume of 2% KI solution, add a few drops of 5% dilute hydrochloric acid and shake together, if the starch solution can turn purple or blue , that is, to prove the presence of peroxide; to remove peroxide is to add a certain amount of tetrahydrofuran and tetrahydrofuran equal volume of FeSO with a mass concentration of 20% in the separatory funnel 4 Solution, after vigorous shaking, the solution will be divided into two layers, the upper layer is the organic...

Embodiment 2

[0028] Embodiment 2: prepare vinylmagnesium chloride according to the following specific steps

[0029](1) Treatment of magnesium chips: take a certain amount of magnesium chips, act for several minutes with a 5% hydrochloric acid solution with a mass concentration, remove the acid solution by suction filtration, wash with water, ethanol, tetrahydrofuran successively, drain and put in a desiccator for subsequent use;

[0030] (2) Check whether there is peroxide in tetrahydrofuran: mix tetrahydrofuran reagent with an equal volume of 2% KI solution, add a few drops of 5% dilute hydrochloric acid and shake together, if the starch solution can turn purple or blue , that is, to prove the presence of peroxide; to remove peroxide is to add a certain amount of tetrahydrofuran and tetrahydrofuran equal volume of FeSO with a mass concentration of 20% in the separatory funnel 4 Solution, after vigorous shaking, the solution will be divided into two layers, the upper layer is the organic ...

Embodiment 3

[0034] Embodiment 3: prepare vinylmagnesium chloride according to the following specific steps

[0035] (1) Treatment of magnesium chips: take a certain amount of magnesium chips, act for several minutes with a 5% hydrochloric acid solution with a mass concentration, remove the acid solution by suction filtration, wash with water, ethanol, tetrahydrofuran successively, drain and put in a desiccator for subsequent use;

[0036] (2) Check whether there is peroxide in tetrahydrofuran: mix tetrahydrofuran reagent with an equal volume of 2% KI solution, add a few drops of 5% dilute hydrochloric acid and shake together, if the starch solution can turn purple or blue , that is, to prove the presence of peroxide; to remove peroxide is to add a certain amount of tetrahydrofuran and tetrahydrofuran equal volume of FeSO with a mass concentration of 20% in the separatory funnel 4 Solution, after vigorous shaking, the solution will be divided into two layers, the upper layer is the organic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com