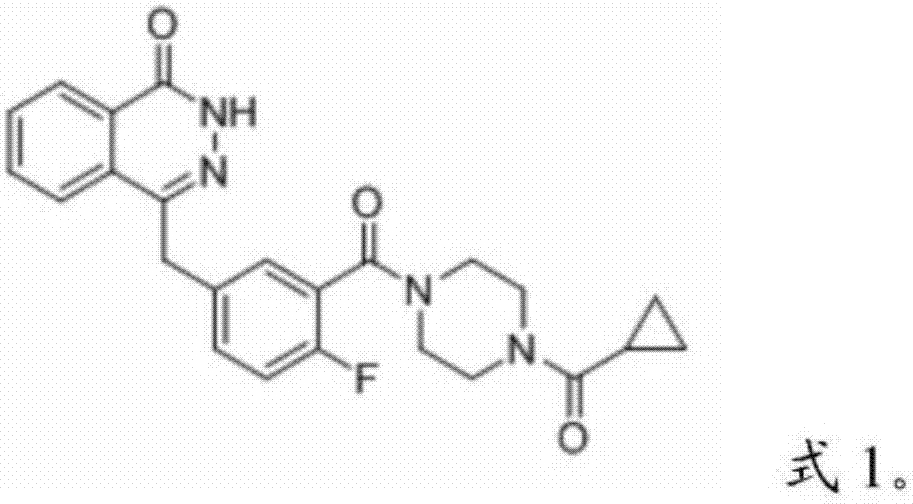

Preparation method of medicine Olaparib for treating ovarian cancer

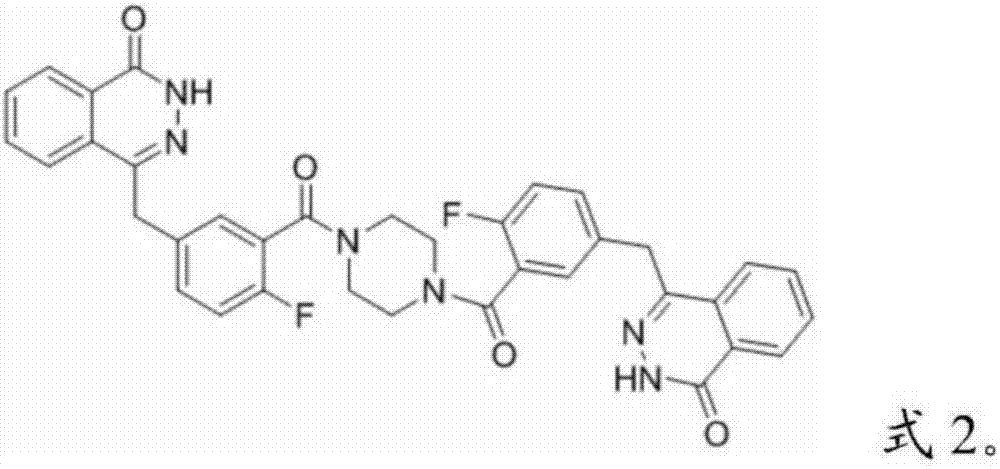

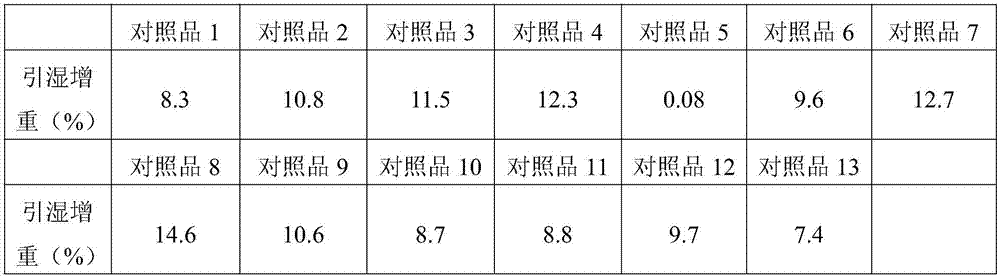

A technology for ovarian cancer and drugs, which is applied in the field of drug preparation, can solve the problem of no removal of special impurities in double-substituted products, and achieve the effect of reduced hygroscopicity and good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 10 g of crude olaparib to 70 mL of a mixed solvent of dimethyl carbonate and isopropyl ether (the volume ratio of dimethyl carbonate and isopropyl ether is 1.0:1), and slowly heat to 45-50° C. Keep stirring at a stirring speed of 110 rpm for 30 minutes, continue to heat up to 60-65°C, stir at a stirring speed of 110 rpm for 30 minutes, dissolve the crude product, and obtain a crude product solution; add activated carbon to the crude product solution, decolorize, filter, and collect the filtrate Slowly lower the temperature, reduce the temperature of the filtrate to 30-35°C, keep warm, control the stirring speed at 110 rpm, and stir for 30 minutes; then cool the filtrate to 5°C or below, control the stirring speed at 150 rpm, and add 0.2g of seed crystals , after controlling the temperature and stirring speed at 150 revs / min to grow the crystal for 2 h, filter, filter the cake with a small amount of dimethyl carbonate and isopropyl ether mixed solvent rinse, suction f...

Embodiment 2

[0033] Add 10 g of crude olaparib to 75 mL of a mixed solvent of dimethyl carbonate and isopropyl ether (the volume ratio of dimethyl carbonate and isopropyl ether is 1.2:1), slowly heat to 45-50 ° C, and Keep stirring at a stirring speed of 110 rpm for 30 minutes, continue to heat up to 60-65°C, stir at a stirring speed of 110 rpm for 30 minutes, dissolve the crude product, and obtain a crude product solution; add activated carbon to the crude product solution, decolorize, filter, and collect the filtrate Slowly lower the temperature, reduce the temperature of the filtrate to 30-35°C, keep warm, control the stirring speed at 110 rpm, and stir for 30 minutes; then cool the filtrate to 5°C or below, control the stirring speed at 150 rpm, and add 0.2g of seed crystals , after controlling the temperature and stirring speed at 150 revs / min to grow the crystal for 2 h, filter, filter the filter cake with a small amount of dimethyl carbonate and isopropyl ether mixed solvent rinse, s...

Embodiment 3

[0036] Add 10 g of crude olaparib to 80 mL of a mixed solvent of dimethyl carbonate and isopropyl ether (the volume ratio of dimethyl carbonate and isopropyl ether is 1.5:1), and slowly heat to 45-50° C. Keep stirring at a stirring speed of 110 rpm for 30 minutes, continue to heat up to 60-65°C, stir at a stirring speed of 110 rpm for 30 minutes, dissolve the crude product, and obtain a crude product solution; add activated carbon to the crude product solution, decolorize, filter, and collect the filtrate Slowly lower the temperature, reduce the temperature of the filtrate to 30-35°C, keep warm, control the stirring speed at 110 rpm, and stir for 30 minutes; then cool the filtrate to 5°C or below, control the stirring speed at 150 rpm, and add 0.2g of seed crystals , after controlling the temperature and stirring speed at 150 revs / min to grow the crystal for 2 h, filter, filter the cake with a small amount of dimethyl carbonate and isopropyl ether mixed solvent rinse, suction f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com