Air cathode, preparation method and sewage treatment system

An air cathode and catalyst layer technology, applied in the fields of materials, energy, and environment, can solve the problems of difficult to achieve practical application, expensive catalysts, serious pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Embodiment 1 Preparation of oxygen-doped graphene catalyst

[0070] Add 100mg of graphene powder into 25mL of concentrated sulfuric acid, react for four hours, gradually add 25mL of 10% dilute sulfuric acid to the reaction system within one hour, then gradually add 75mL of deionized water within two hours, and finally add 2mL of hydrogen peroxide Terminate the reaction and complete the oxidation process. During the whole process of the reaction, the whole system was placed in an ice bath and kept stirring. Then dry at 60°C for 12 hours to obtain oxygen-doped graphene. Utilize XPS to test the composition of the obtained oxygen-doped graphene, scanning spectrogram and O1s peak division result are as follows Figure 10 shown.

Embodiment 2

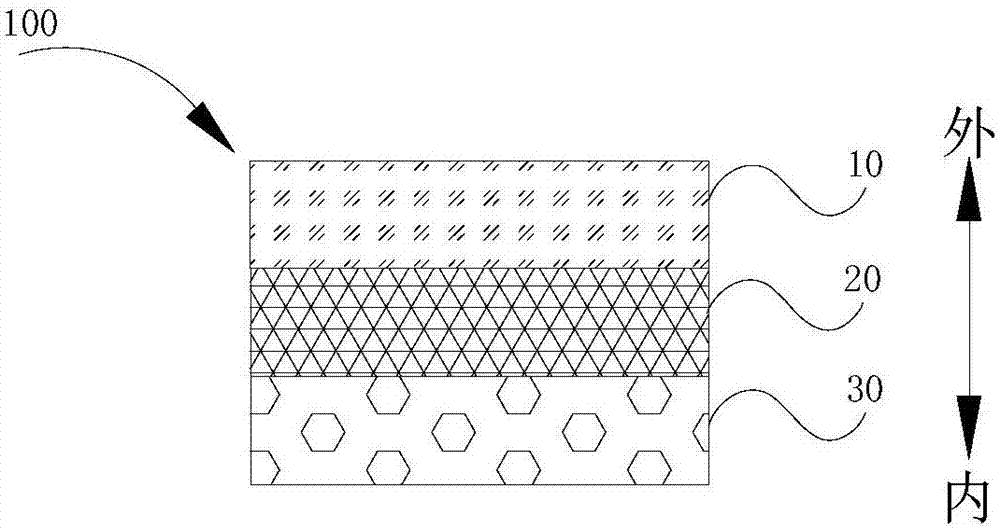

[0071] Example 2 Preparation of air cathode

[0072] First the diffusion layer is prepared. The mass ratio of carbon black to PTFE on the diffusion layer is controlled at 3:10, that is, the loading of carbon black is about 13mg / cm 2 , while the load of PTFE is about 44mg / cm 2 , according to 11.34cm 2 Weigh carbon black and PTFE, add appropriate amount of ethanol to increase the viscosity of the mixture. Ultrasonic mixing in a water bath for about 1 min forms a viscous substance. The viscous substance is rolled on the flat plate for 2-3 times, and then directly pressed on the stainless steel mesh or titanium mesh, and pressed under the condition of 4.5MPa for 10 minutes. Put the pressed diffusion layer into a muffle furnace, and heat-treat at 340°C for 20 minutes to make it solidify and form.

[0073] Next, a catalyst layer is prepared. Weigh 300 mg of the catalyst formed by carbon black, add 50 μL of 60% PTFE and 450 μL of deionized water, and add 300 μL of ethanol, and ...

Embodiment 3

[0075] Example 3 Preparation of Air Cathode

[0076] Referring to Example 2, the difference is that graphene is used as a catalyst, and the loading capacity of the catalyst is 17.6 mg / cm 2 . Among them, the XPS spectrum of graphene and the O1s peak splitting results are as follows Figure 11 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com