Snow anti-skid track structure design for automobile

A technology of anti-slip track and structural design, applied in the field of transportation, can solve problems such as heavy workload, achieve the effects of reducing burden, preventing rollover accidents, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

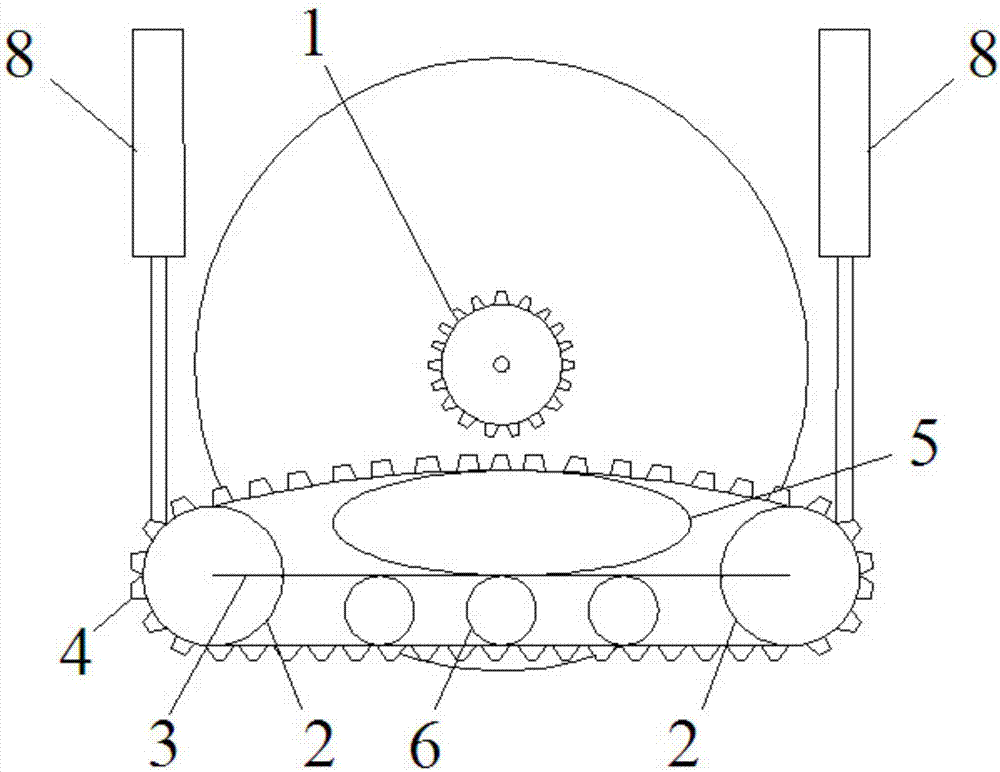

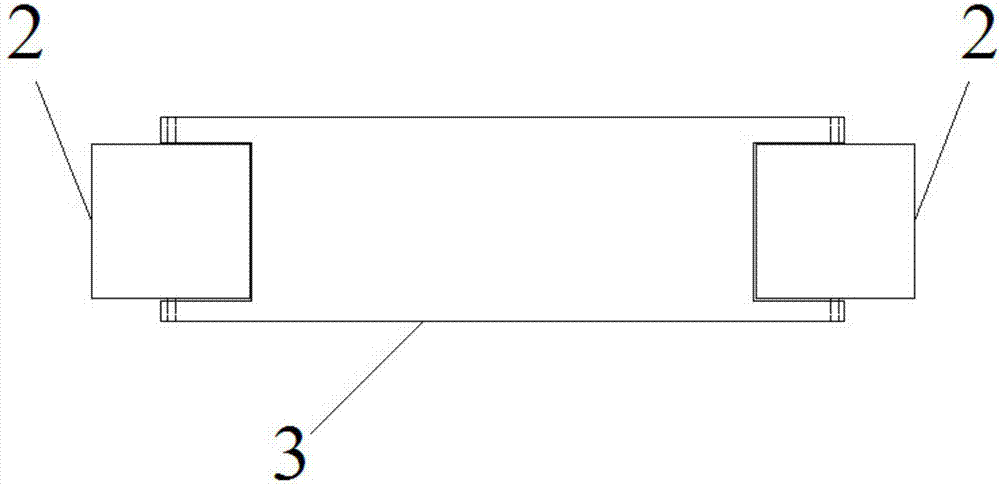

[0022] The present invention provides a structure design of a snow skid track for automobiles, specifically as Figure 1-5 As shown, it includes a driving wheel 1, a tensioning wheel 2, a bracket 3, a crawler 4, an air cushion 5, a supporting wheel 6, a side plate 7 and an automatic lifting mechanism 8;

[0023] Such as Figure 1-2 As shown, the driving wheel 1 is installed on the outside of the wheel axle, and the axle of the driving wheel 1 is collinear with the wheel axle. The power of the driving wheel 1 is provided by the motor that provides power to the wheels. The driving wheel 1 is a gear mechanism in order to transmit torque. For the crawler, there are two tensioning wheels 2, two tensioning wheels 2 are located below the driving wheel 1, the axles of the two tensioning wheels 2 are parallel to the wheel axles, and the two tensioning wheels 2 are on the same horizontal plane to ensure The lower crawler is parallel to the ground to increase the contact area between the cr...

Embodiment 2

[0029] On the basis of Embodiment 1, the present invention also proposes Embodiment 2.

[0030] The difference from Embodiment 1 is that the outer ring of the crawler 4 is provided with a through hole that matches the gear of the driving wheel 1. The other structure is the same as that of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com