Full-automatic assembly device of LED string lights and welding and detection mechanism thereof

A technology of LED light string and detection mechanism, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of high production and management costs, difficult quality control, and a large number of operators, and improve the delivery rate of good products. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0038] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the following embodiments and features in the embodiments can be combined with each other.

[0039] Up, down, left, and right in this embodiment are only for the purpose of description, and are not used to limit the applicable scope of the present invention. Changes or adjustments of their relative relationships should be regarded as the applicable scope of the present invention.

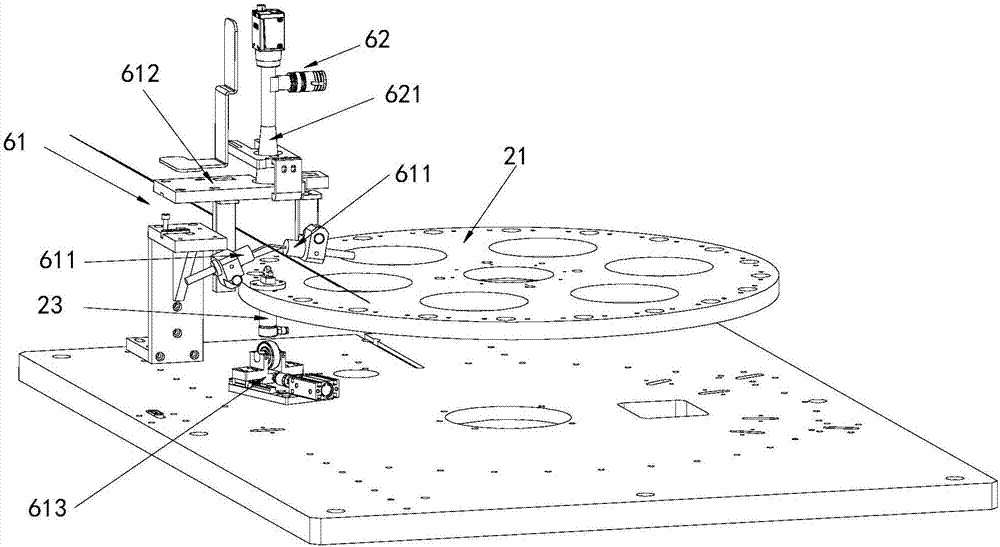

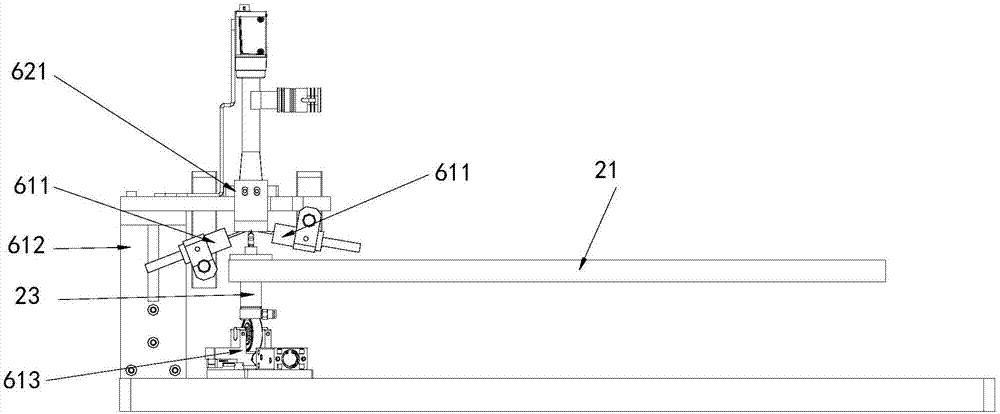

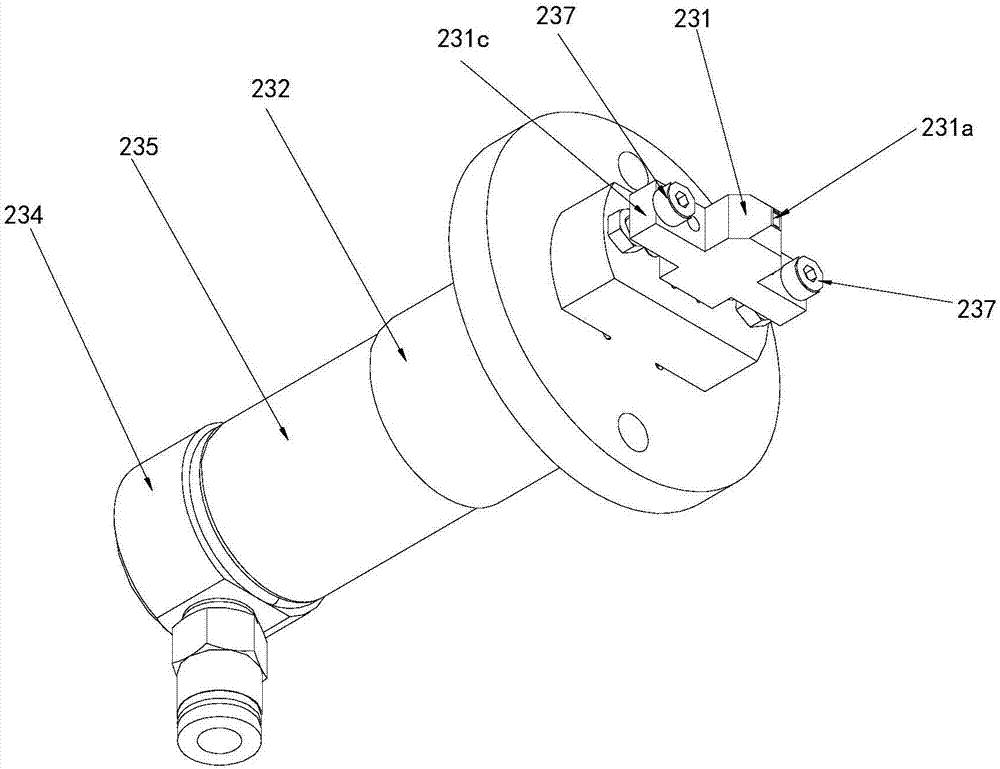

[0040] like figure 1 , 2 As shown, the fully automatic assembly equipment for LED light strings in the embodiment of the present invention includes a turntable conveying assembly 20, and the turntable conveying assembly 20 includes a turntable 21, a plurality of LED fixing fixture assemblies arranged at intervals on the circumference of the turntable 21, and for driving The turntable driving device for rotating the turntable 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com