Circulation solid poultry feed smashing device

A pulverizing device and a cyclic technology, applied in the field of circulating poultry solid feed pulverizing devices, can solve the problems of insufficient feed pulverization effect, uneven size of feed particles, etc., so as to avoid excessive concentration of falling, improve pulverization effect, and ingenious structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

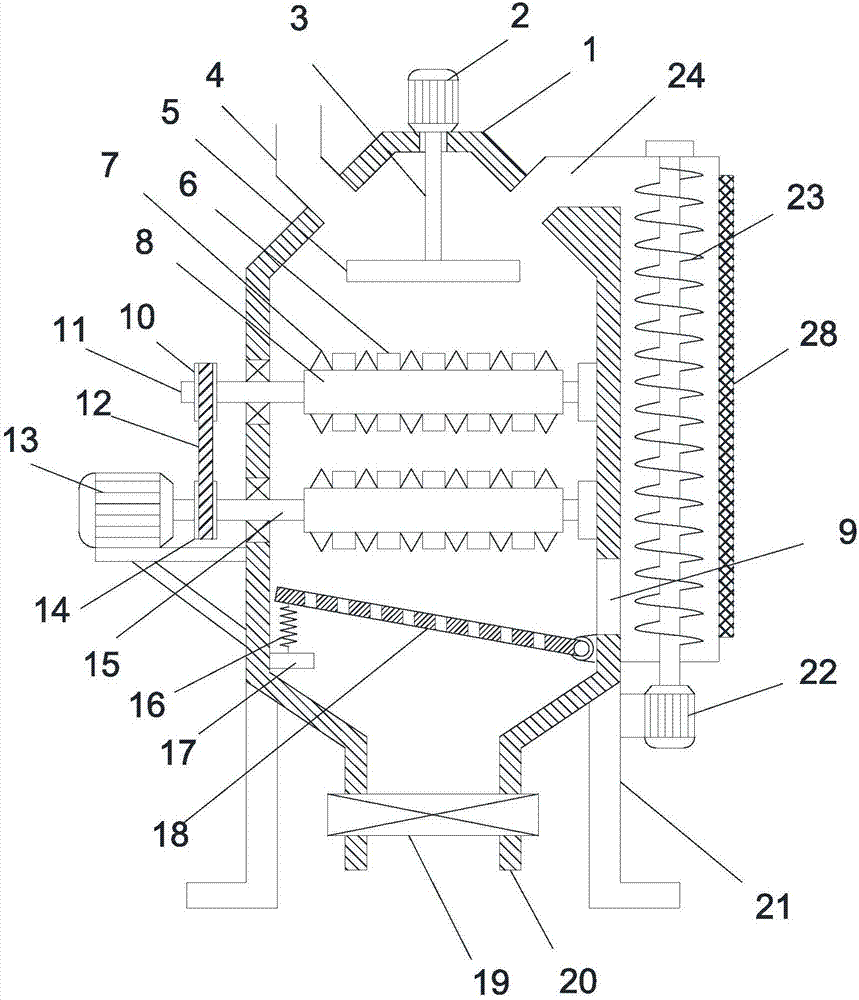

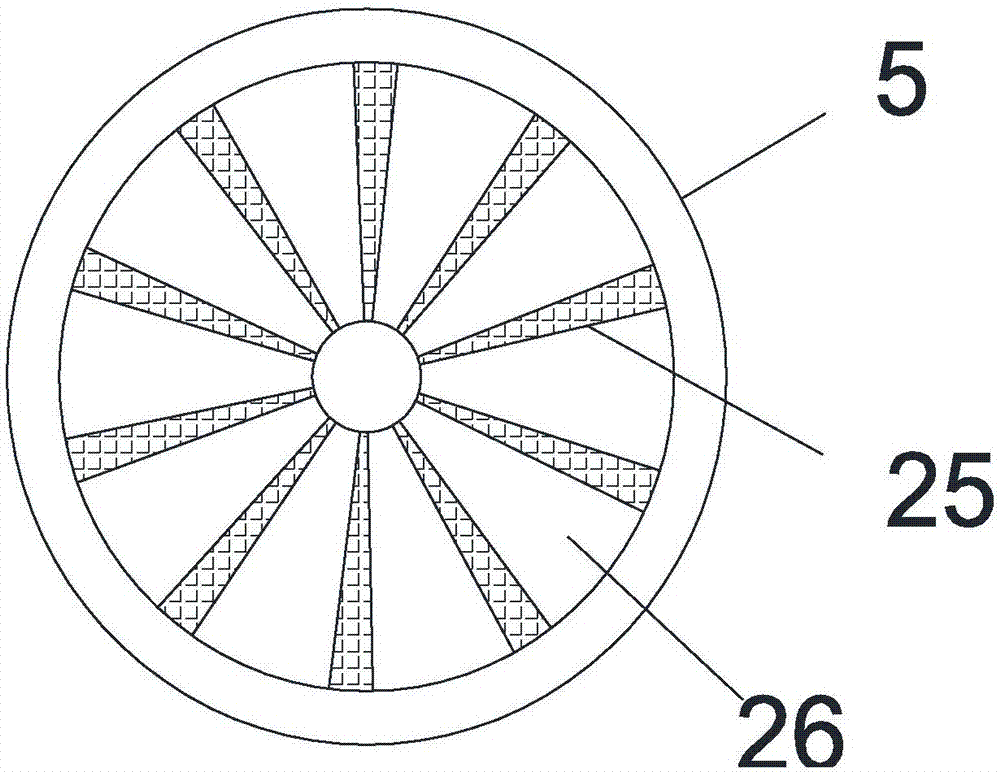

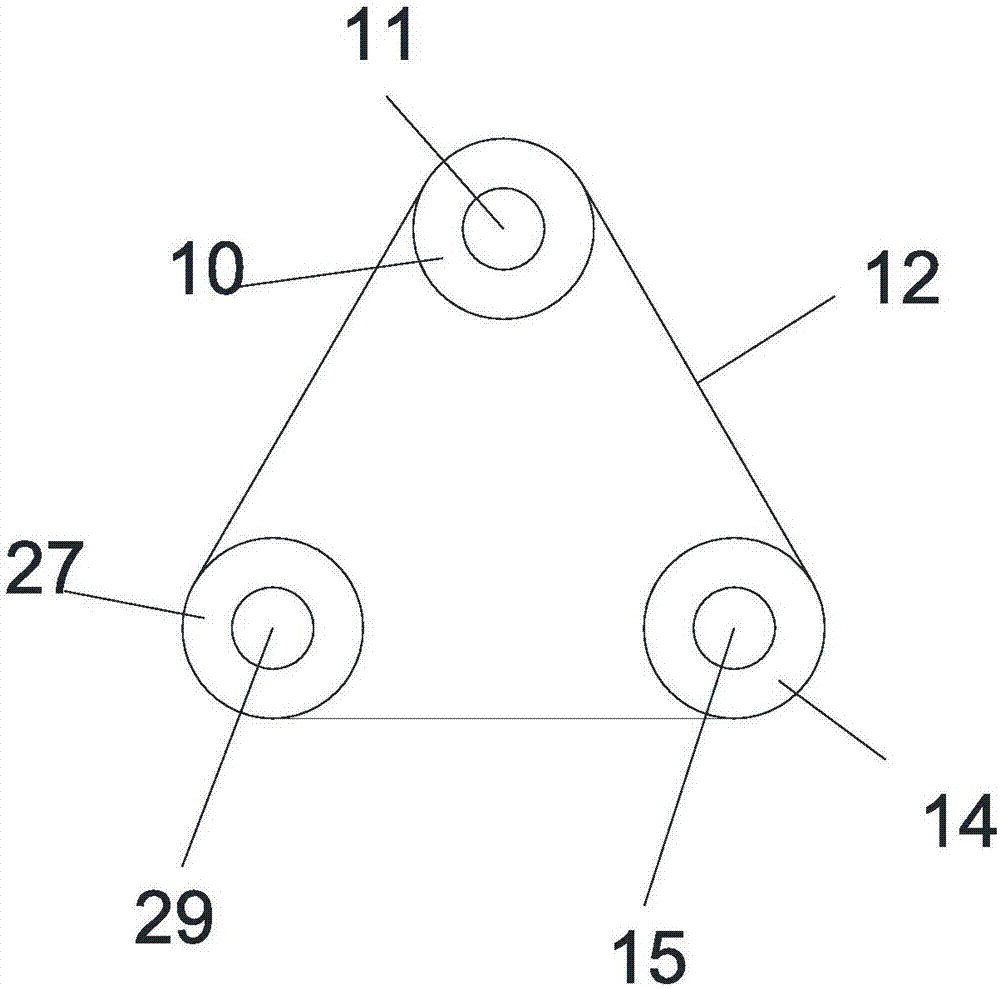

[0019] see Figure 1-3 , a circulating poultry solid feed crushing device, comprising a crushing box 1, the top of the crushing box 1 is provided with a feed pipe 4, the top of the crushing box 1 is provided with a first motor 2, and the output shaft of the first motor 2 is coaxial A rotating shaft 3 is fixedly installed, and the rotating shaft 3 is located inside the crushing box 1, and the bottom end of the rotating shaft 3 is provided with a dispersing disc 5; Radial extension is provided with several dispersing rods 25, the angles between the center of circles between adjacent dispersing rods 25 are equal, and a blanking through hole 26 is formed between adjacent dispersing rods 25; Shaft 15, the first driven shaft 11 and the second driven shaft 29, the driving shaft 15 is provided with the driving pulley 14, the first driven shaft 11 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com