Cable fixing and mounting method

An installation method and cable technology, applied in the field of fixed installation of cables, can solve the problems of damage to the generator set, signal interruption, affecting power generation, etc., and achieve the effect of small requirements, solving wear and tear, and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

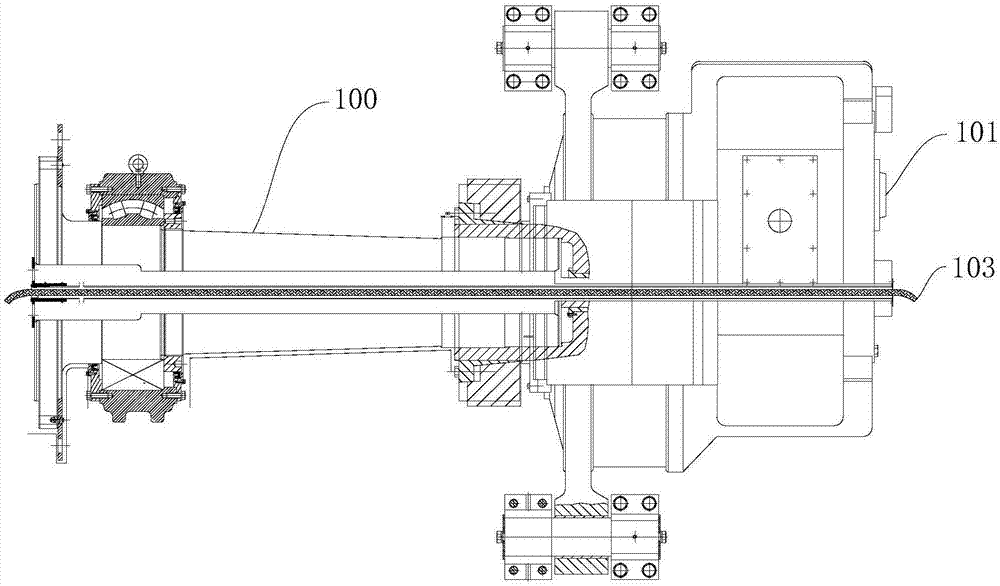

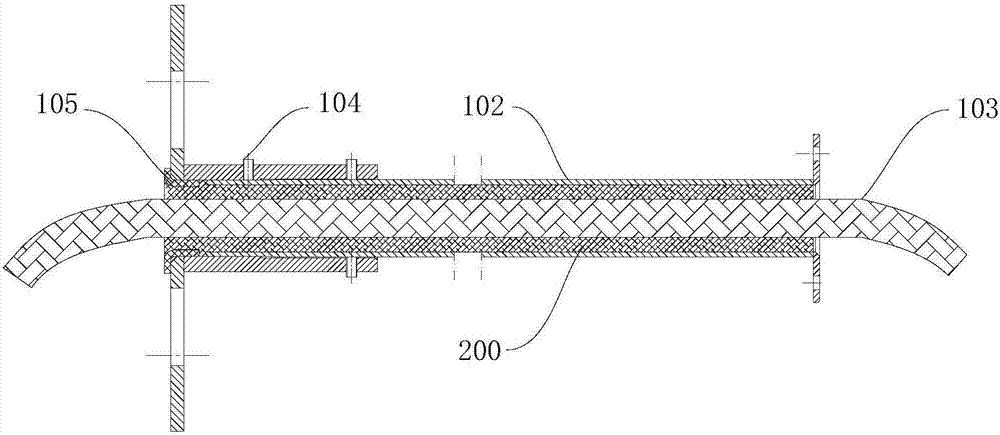

[0053] This embodiment provides a cable fixing and installation method, the apparatus used in this method and the place where it is implemented can refer to Figure 1 to Figure 3 .

[0054] The cable fixed installation method includes the following steps:

[0055] A threading pipe 102 is installed inside the main shaft 100 and the gearbox 101;

[0056] The communication cable 103 is threaded in the threading pipe 102;

[0057] Disassemble the slip ring;

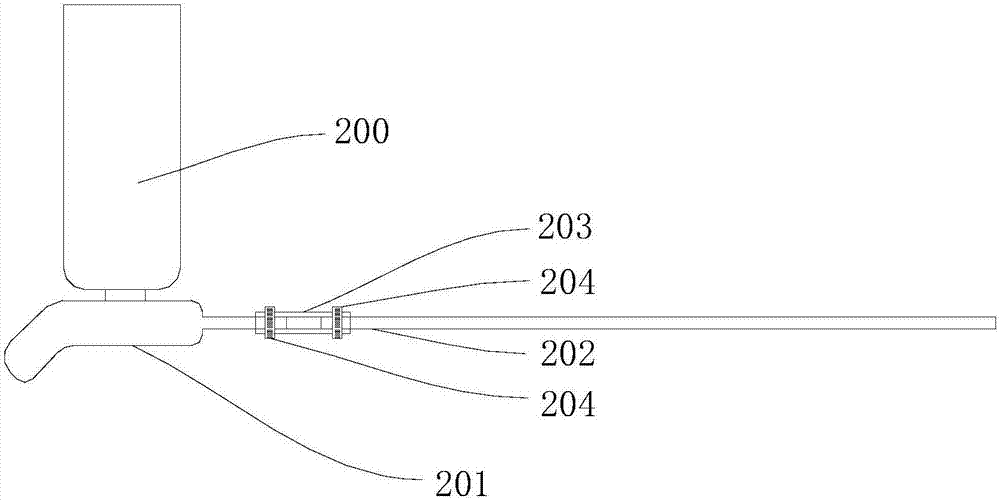

[0058] Assemble foam gun 201, foam pipe 202 and hose 203 with hoop 204;

[0059] Insert the foam tube 202 into the gap between the communication cable 103 and the threading pipe 102, insert it from the end of the threading pipe 102 close to the main shaft 100 and insert it to the other end of the threading pipe 102, and the cable skin cannot be damaged when inserting;

[0060] Foam at a speed of 0.6-0.7m / min and gradually pull away from the foam tube 202 without damaging the cable sheath;

[0061] Clean up the rubbish prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com