Cell pole piece and lithium ion battery cell

A pole piece and cell technology, which is applied in the field of secondary battery cells, can solve the problems of low energy density and heavy cell weight, and achieve the effects of increasing energy density, reducing weight, and stabilizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

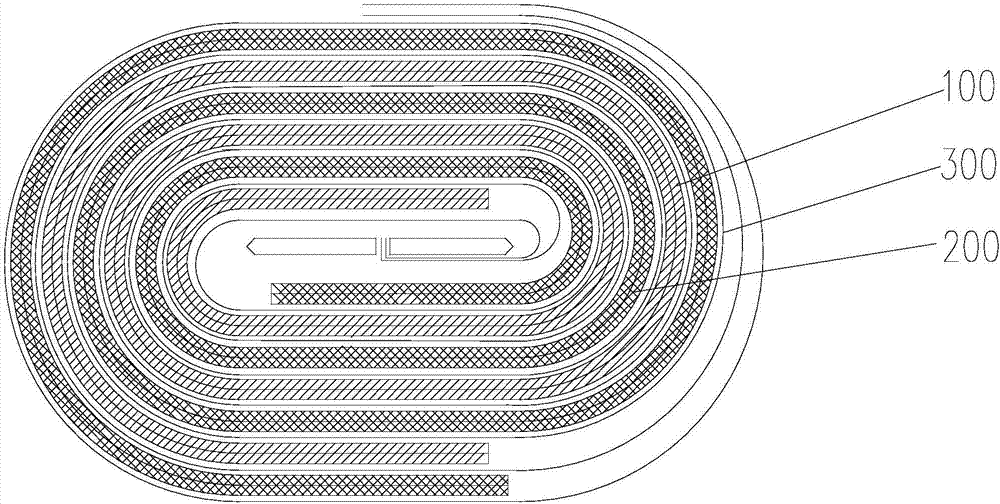

[0023] see figure 1 , a lithium-ion battery cell, comprising a positive cell pole piece 100 wound together after lamination, a negative battery pole piece 200 and a separator 300, the separator 300 is located on the positive battery pole piece 100 and the negative battery pole piece 200 between.

[0024] see figure 1 and figure 2 , both the positive battery pole piece 100 and the negative battery pole piece 200 are battery pole pieces. The electrode sheet of the battery cell includes a current collector 1 and an active material layer 2. The current collector 1 is provided with a plurality of through holes 11, and the plurality of through holes 11 are a plurality of through holes arranged in a matrix. Preferably, the shape of the through hole 11 is circular, polygonal or irregular. When the through hole 11 is circular, the diameter of the through hole 11 is 1-10 mm. In this embodiment, the diameter of the through hole 11 is 9 mm. The through hole 11 is coated with a cond...

Embodiment 2

[0028] The difference between this embodiment and Embodiment 1 is that the number of through holes 11 of the positive electrode sheet and the negative electrode sheet is 100, arranged in a 5×20 (number of rows×number of columns) arrangement.

Embodiment 3

[0030] The difference between this embodiment and Embodiment 1 is that the number of through-holes 11 of the positive electrode sheet and the negative electrode sheet is 80, arranged in a 4×20 (number of rows×number of columns) arrangement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com